Degradation type composite material

A composite material and polymer technology, applied in the field of degradable composite materials, can solve the problem of high production cost, achieve the effects of good opening, good compatibility, and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

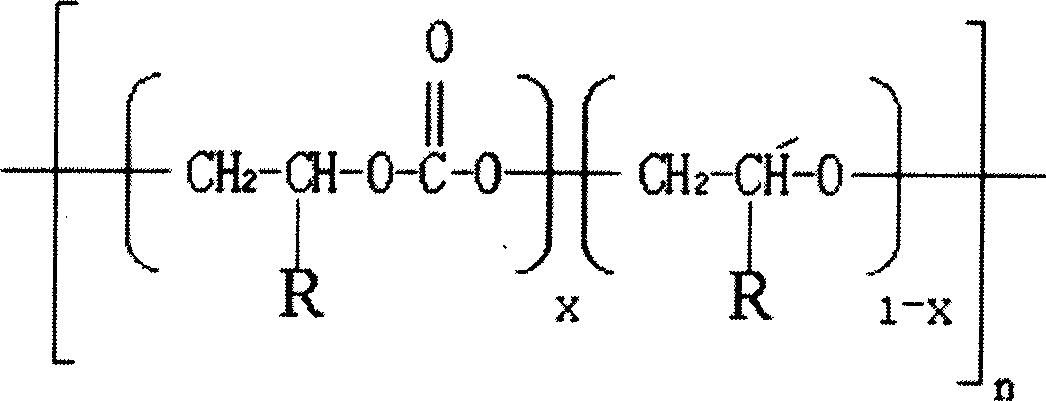

Image

Examples

Embodiment 1

[0026] Embodiment 1: take each component by following formula (weight part):

[0027] Carbon Dioxide Polymer 100

[0028] PBS 10

[0029] Acetyl tri-n-butyl citrate 10

[0030] Maleic anhydride end-capping agent 1 Mix the components in a high-speed mixer for 5 minutes, then cool and stir, discharge at 20-30°C, and then plasticize, extrude and granulate in a twin-screw or single-screw extruder , the compound is obtained through sterilized and sealed packaging. The temperature setting of the extruder is: 70-120°C in the feeding section, 130-155°C in the plasticizing section, and 130-150°C in the extrusion section. The screw speed is: 300 rpm. The tensile strength (Mpa) of the composite material is 2.64Mpa, and the elongation at break (%) is 846%.

Embodiment 2

[0031] Embodiment 2: take each component by following formula (weight part)

[0032] Carbon Dioxide Polymer 100

[0033] PBS 25

[0034] Acetyl tri-n-butyl citrate 5

[0035] Maleic anhydride end-capping agent 4 Mix the components in a high-speed mixer for 5 minutes, then cool and stir, discharge at 20-30°C, and then plasticize and extrude pellets in a twin-screw or single-screw extruder , the compound is obtained through sterilized and sealed packaging. The temperature setting of the extruder is: 70-120°C in the feeding section, 130-155°C in the plasticizing section, and 130-150°C in the extrusion section. The screw speed is: 300 rpm. The tensile strength (Mpa) of the composite material is 12.10Mpa, and the elongation at break (%) is 598%.

[0036] Embodiment 2: take each component by following formula (weight part)

[0037] Carbon Dioxide Polymer 100

[0038] PBS 20

[0039] Maleic anhydride end-capping agent 2 Mix the components in a high-speed mixer for 5 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com