Patents

Literature

34results about How to "Increase filling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

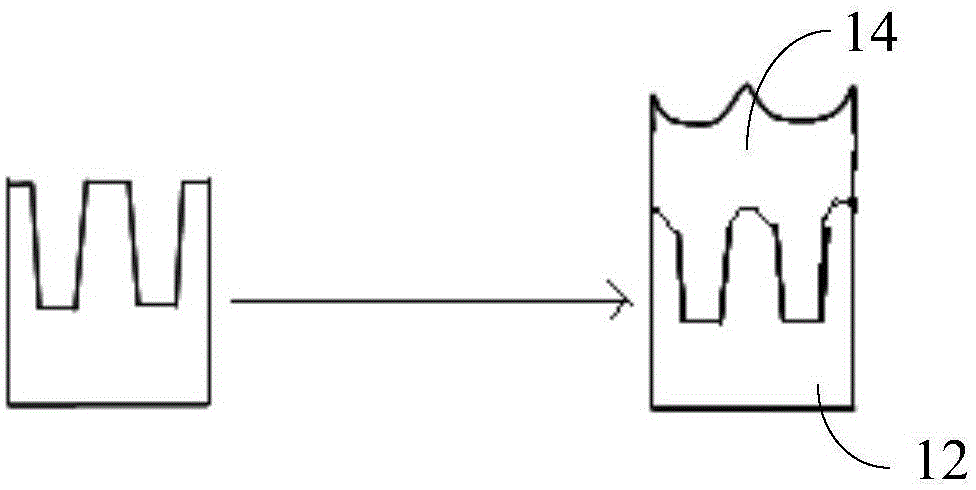

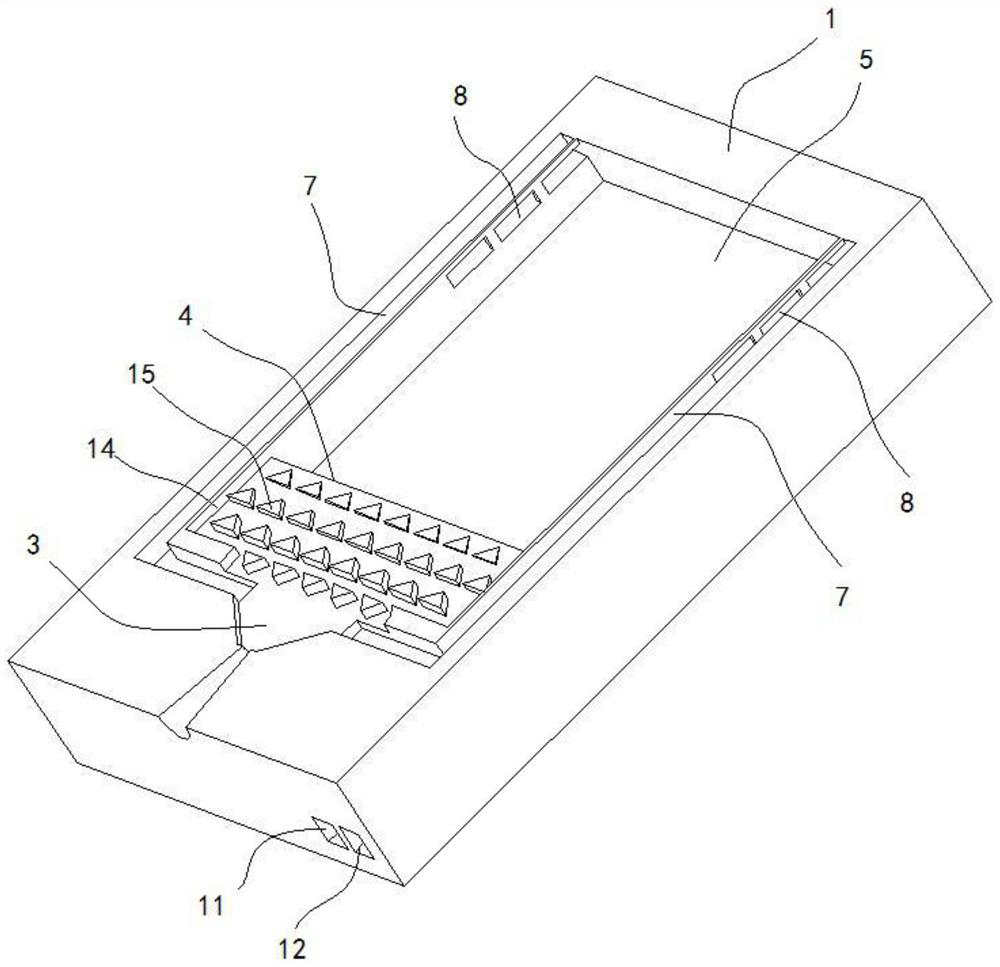

Preparing method of superhydrophobic concave angle T-shaped microcolumn structure

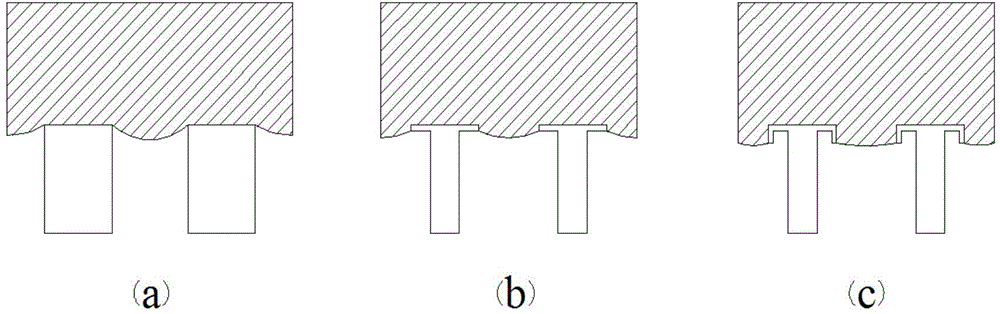

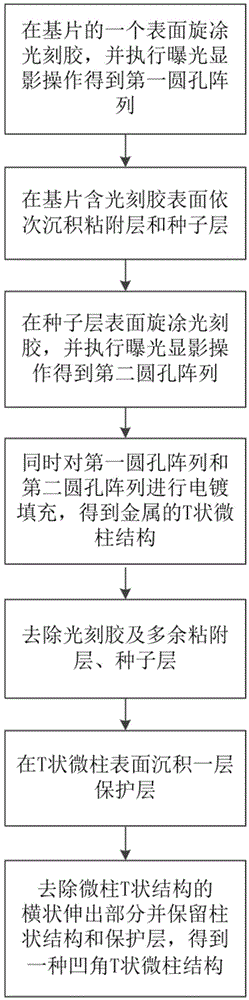

InactiveCN104649216AAvoid multiple sputteringAvoid filling multiple timesDecorative surface effectsCoupling light guidesProcess windowProtection layer

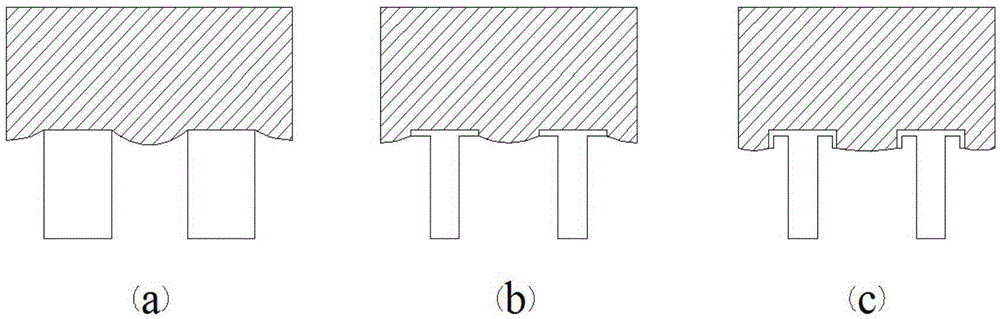

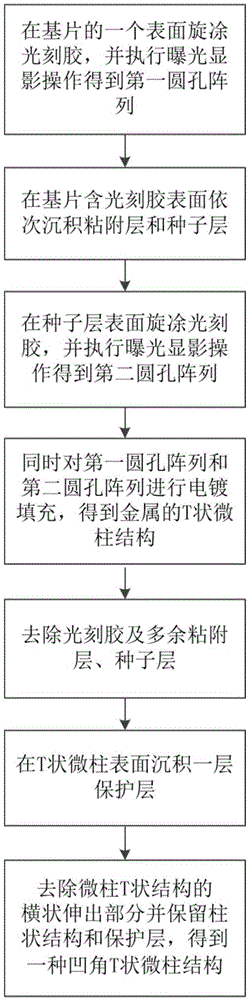

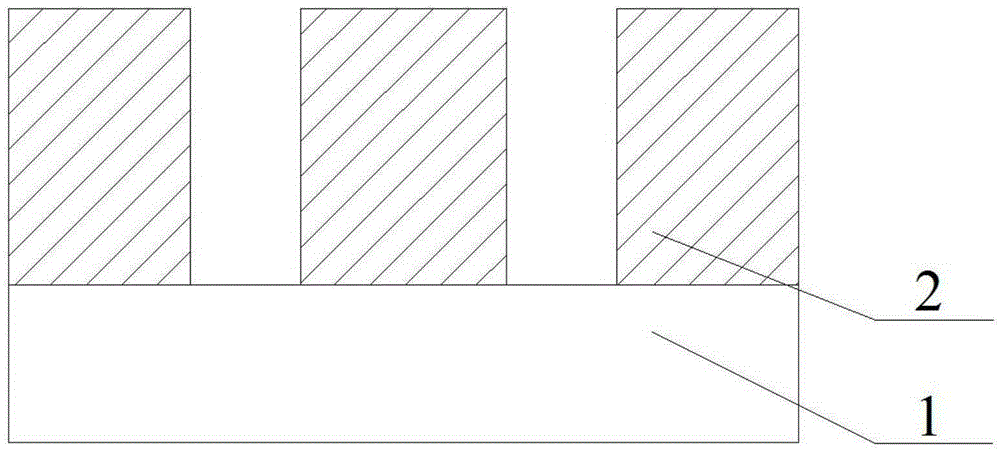

The invention discloses a preparing method of a superhydrophobic concave angle T-shaped microcolumn structure. The method comprises the steps of (a), rotationally coating photoresist on one surface of a chip and executing developing operation to obtain a first round hole array; (b), depositing an adhesion layer and a seed layer on the surface of the photoresist in sequence; (c) rotationally coating the photoresist on the surface of the seed layer and executing the developing operation to obtain a second round hole array; (d), performing plating and filling on the first round hole array and the second round hole array to obtain a metal T-shaped microcolumn structure; (e) removing the photoresist and surplus adhesion layer and seed layer; (f), depositing a protection layer on the surface of the T-shaped microcolumn; (g), removing a lateral extending part of the microcolumn T-shaped structure and remaining a columnar structure and the protection layer to obtain one concave angle T-shaped microcolumn structure. According to the method, a target structure of different sizes can be prepared controllably, a process window is wide, the repeatability is good, the chemical stability is high, and the superhydrophobic concave angle T-shaped microcolumn structure has excellent superhydrophobic performance and self-cleaning capacity.

Owner:HUAZHONG UNIV OF SCI & TECH

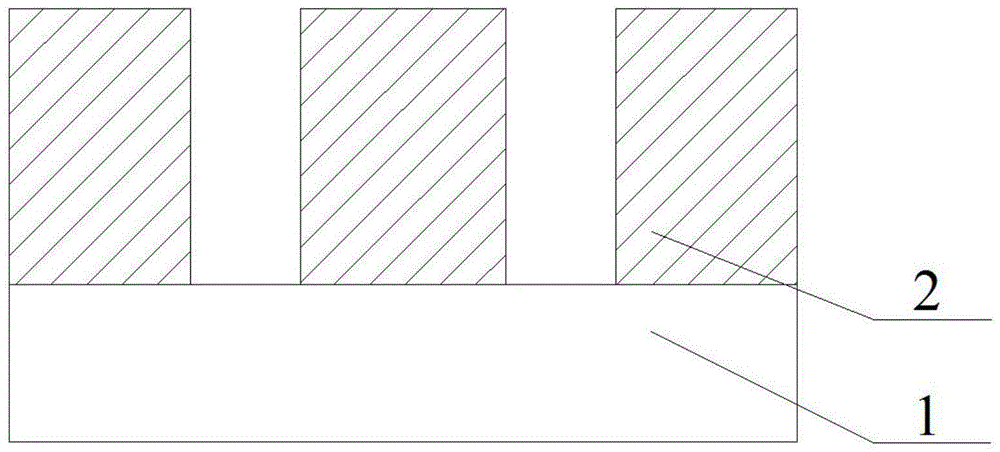

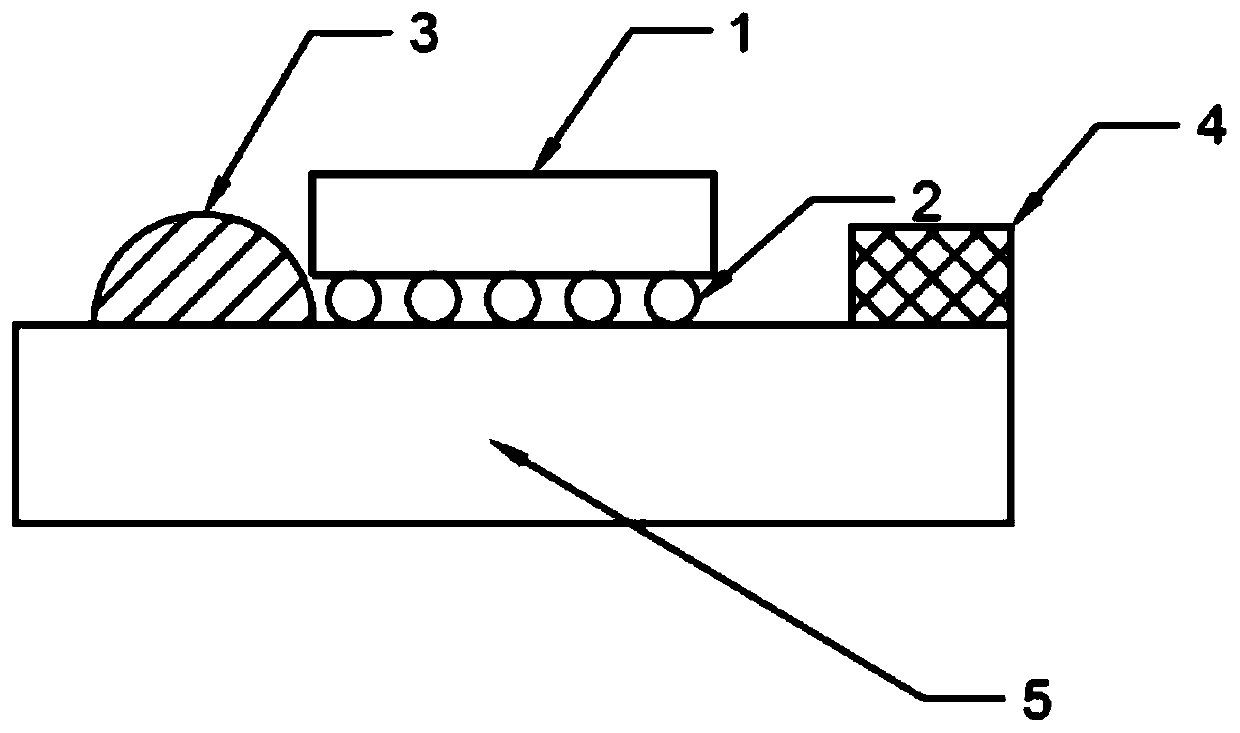

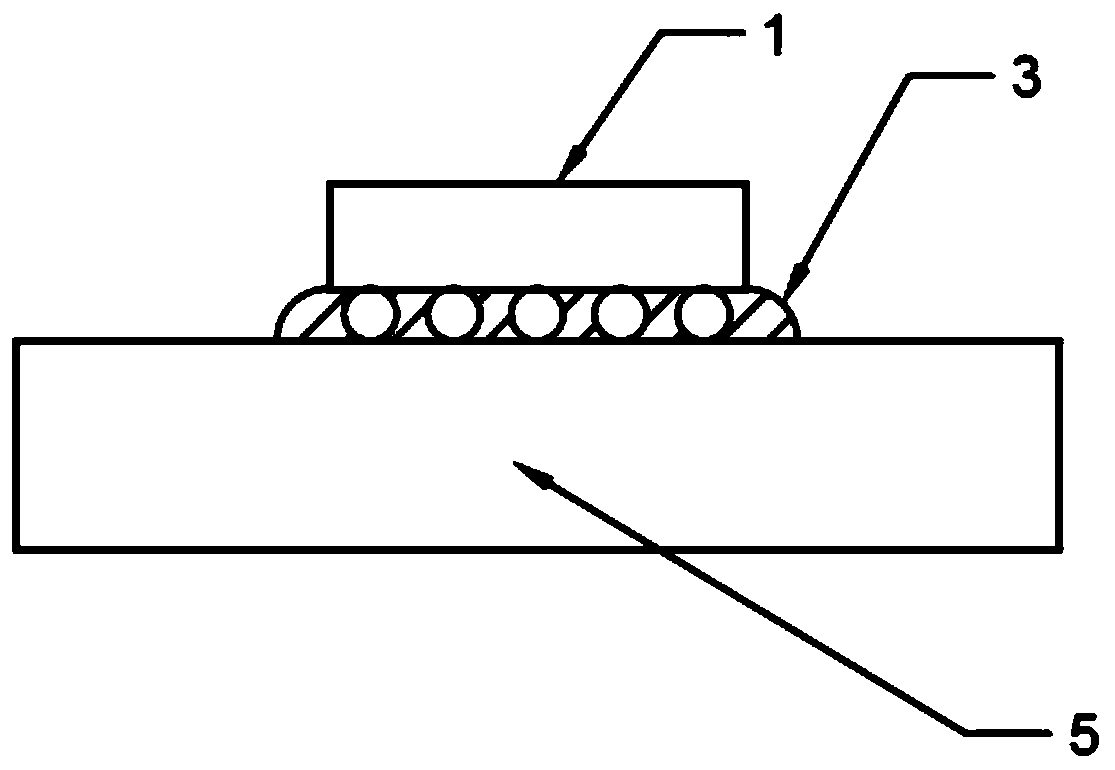

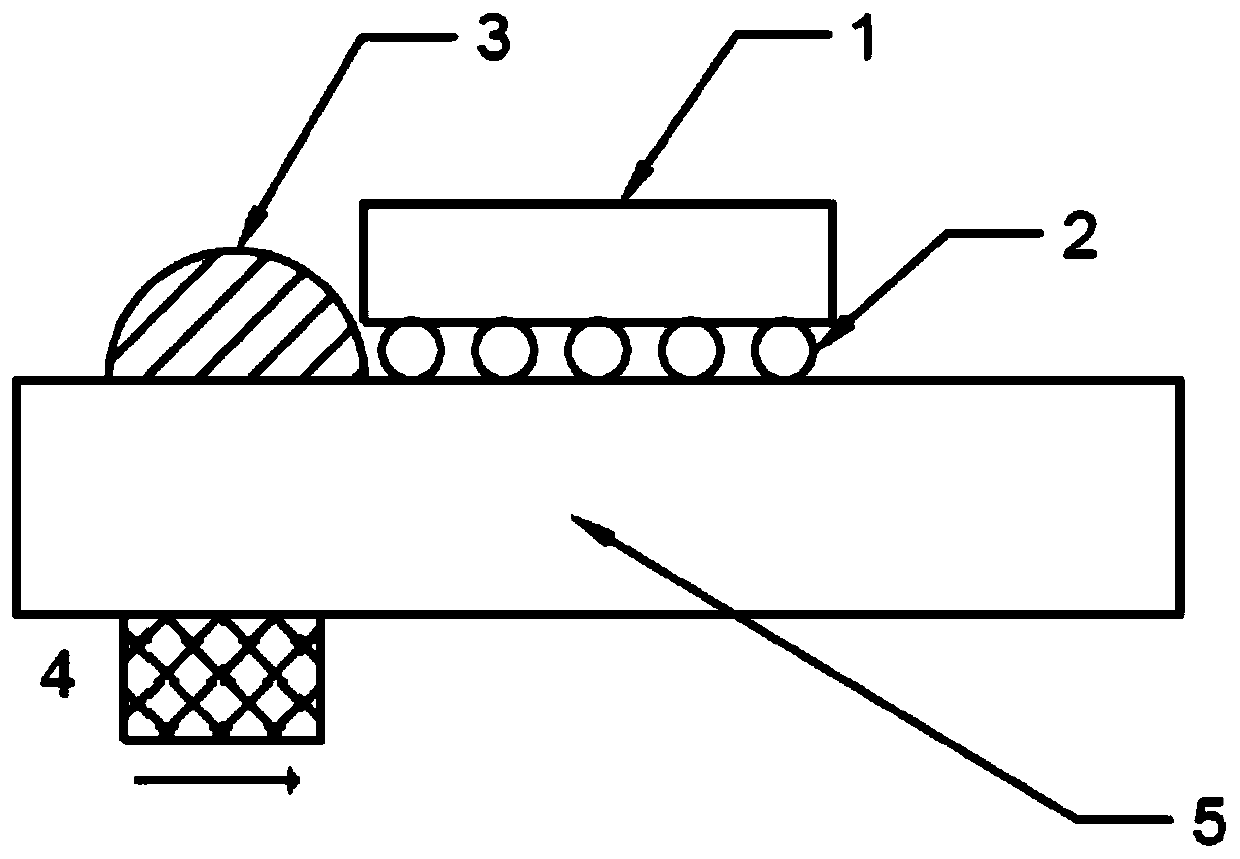

Electronic packaging device and underfilling method

InactiveCN110429066AImprove reliabilityImprove structural strengthSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageThermal expansion

The invention belongs to the technical field of semiconductor packaging, and particularly relates to application of magnetic materials as a bottom glue filling filler in an electronic packaging device, an electronic packaging device and an underfilling method thereof. The magnetic materials are taken as the bottom glue filling filler to achieve the filling of small gaps, reduce stress impact caused by large difference of the thermal expansion coefficient between a substrate and a chip and / or between a base and a mother board, improve the reliability, structural strength and the auto-dropping performance of the electronic package device.

Owner:SHANGHAI XIANFANG SEMICON CO LTD

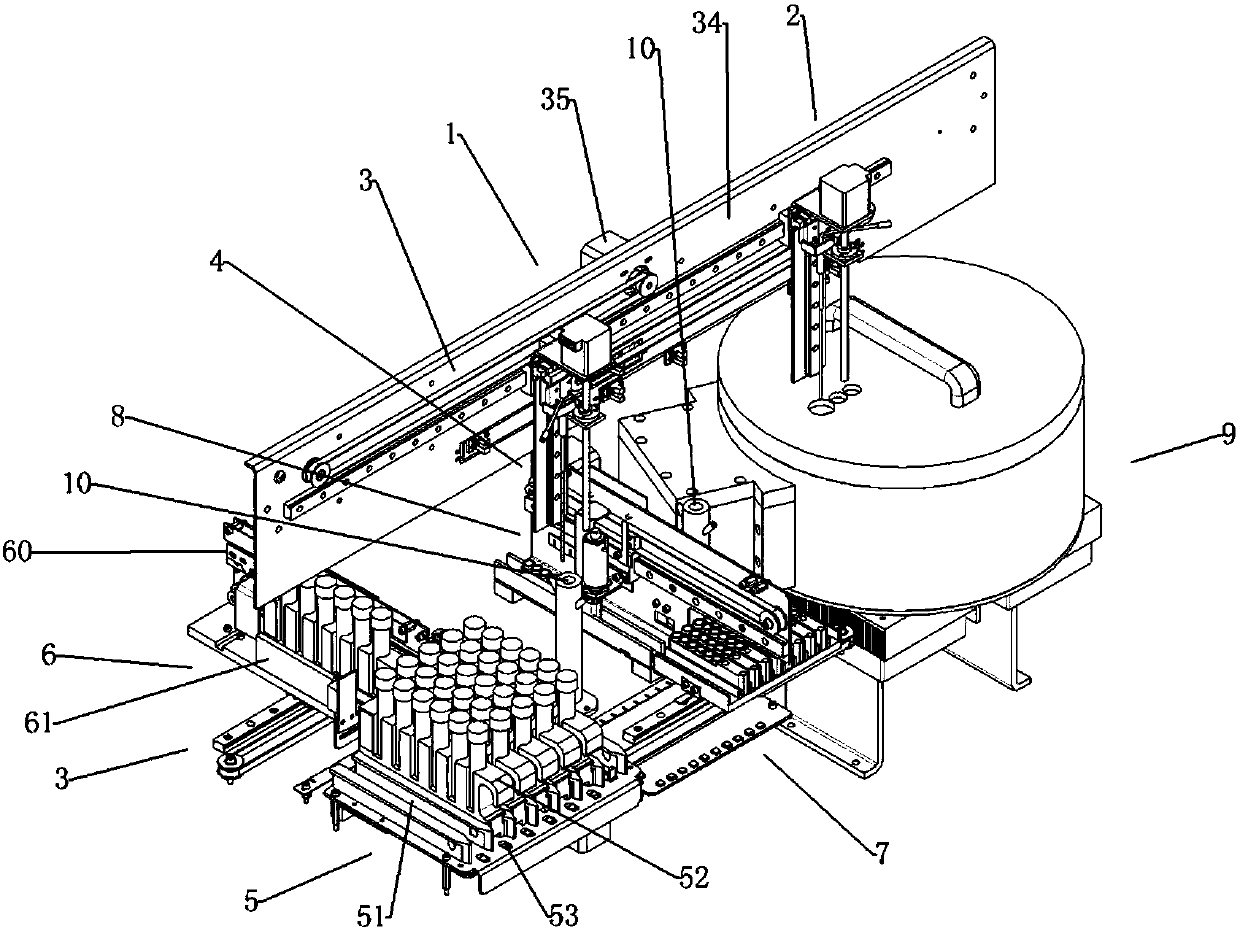

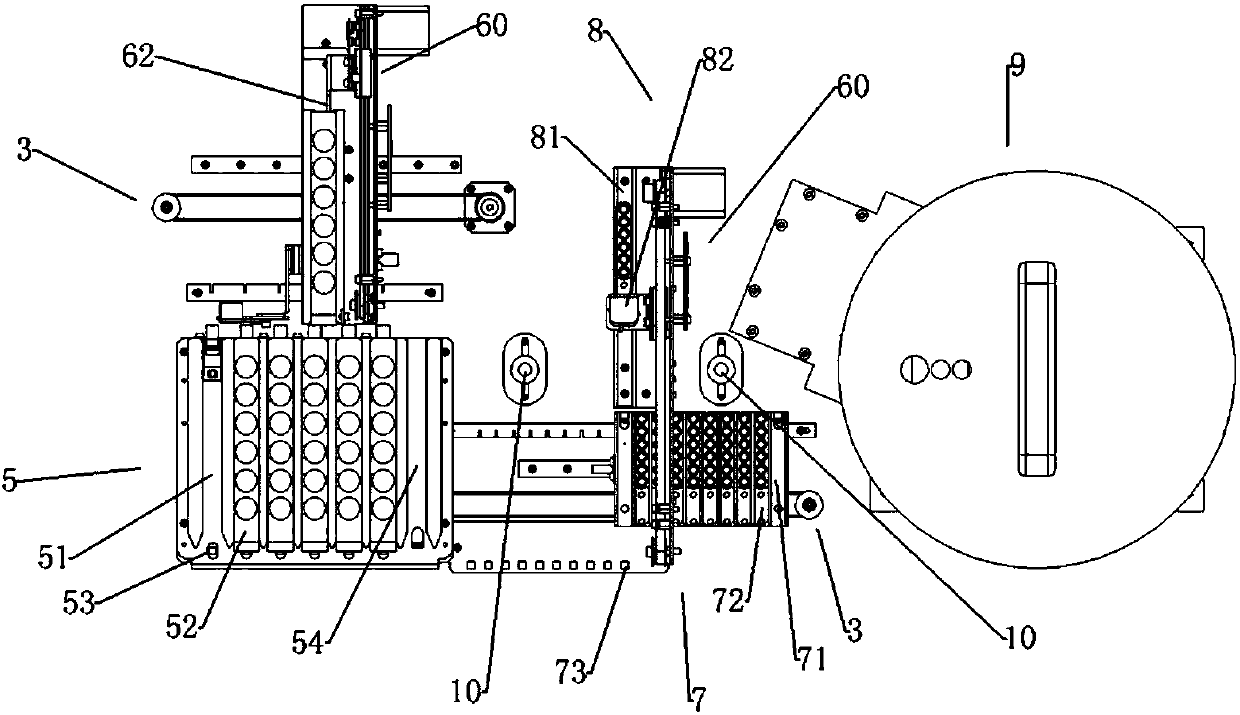

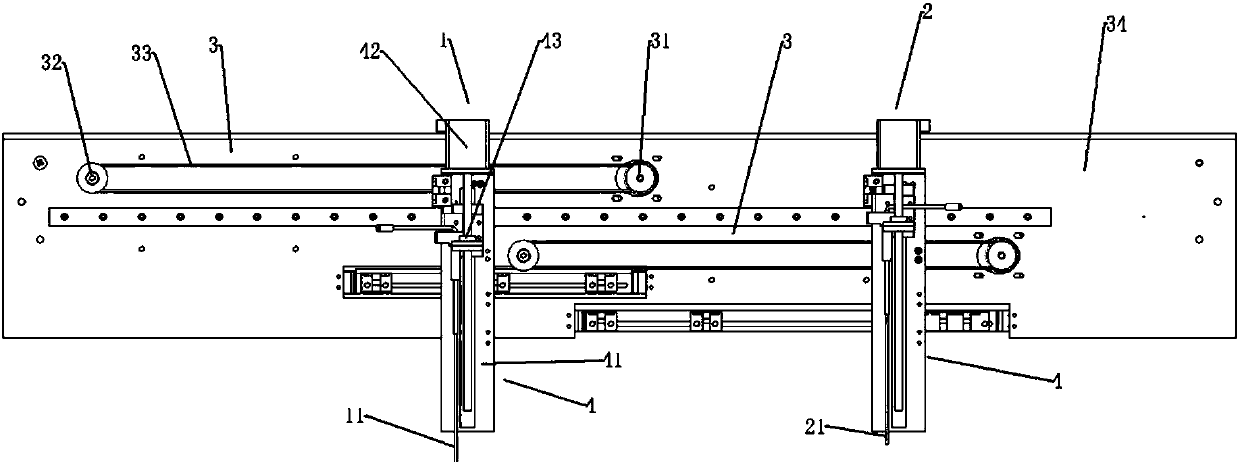

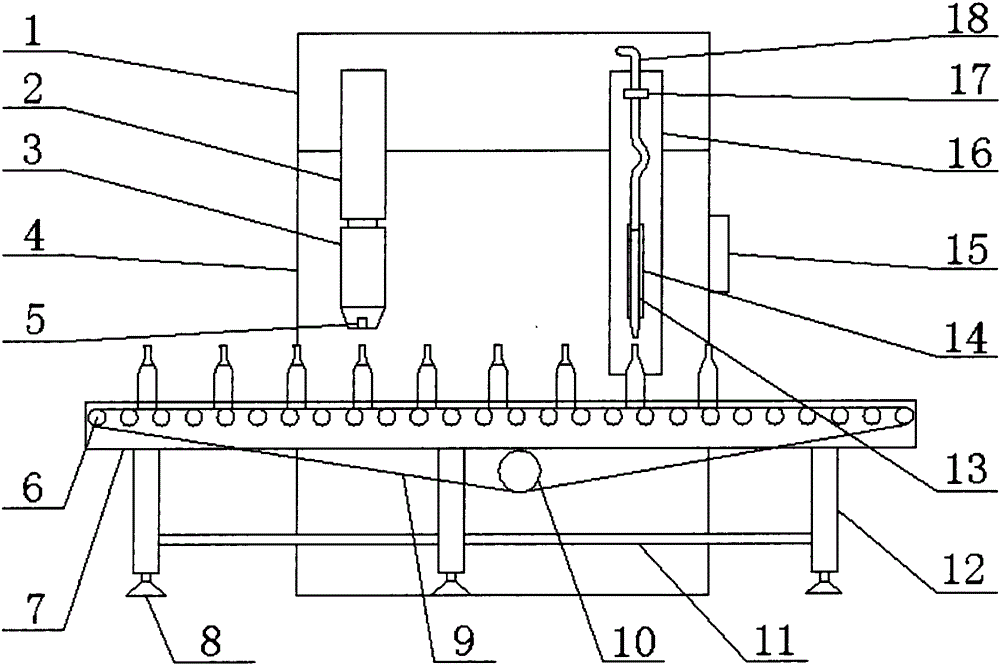

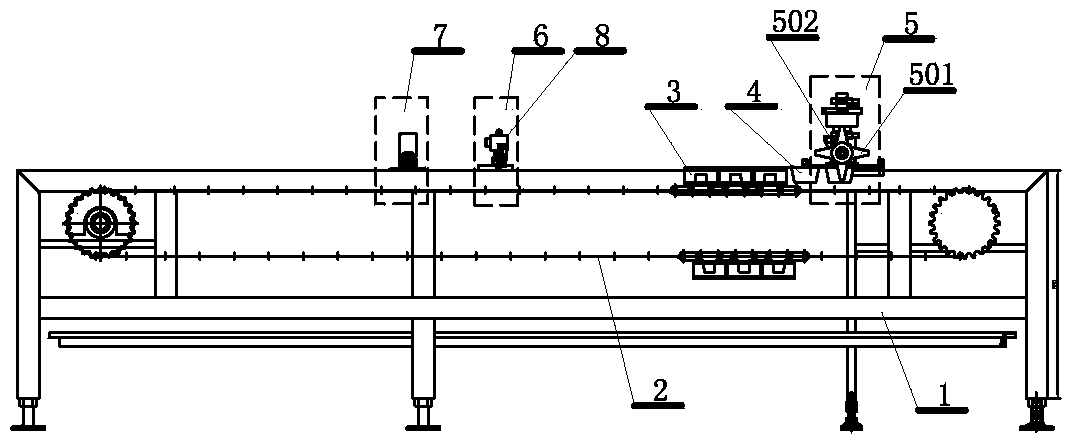

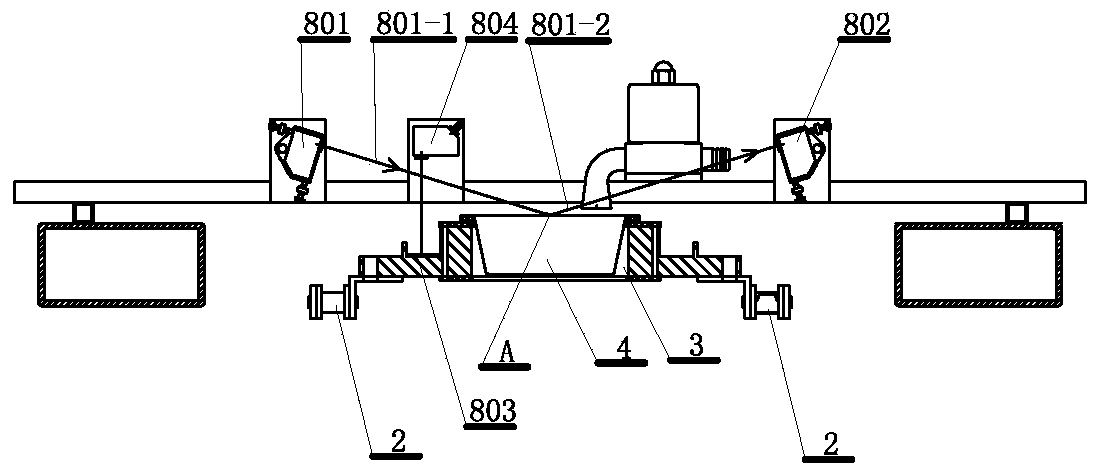

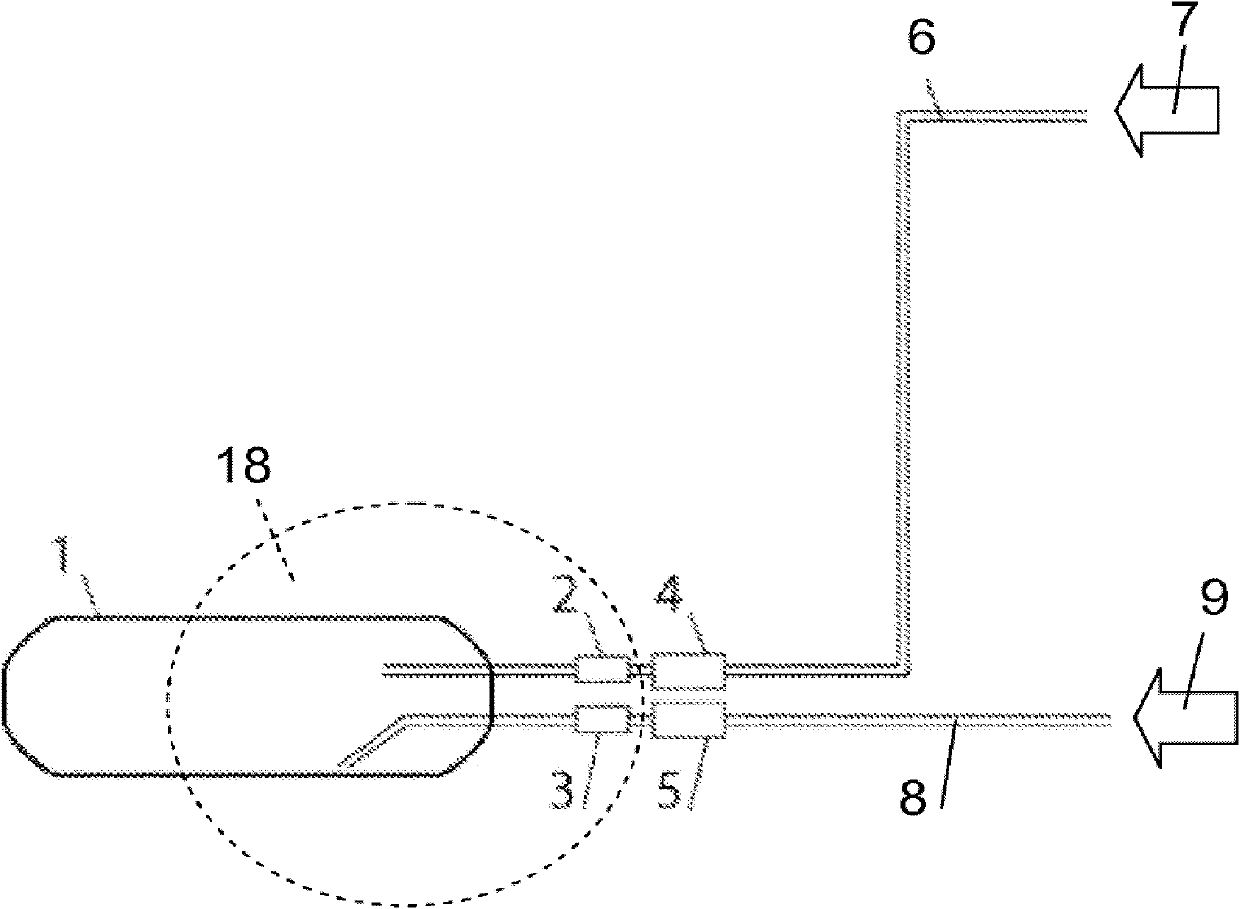

Sampling device of full-automatic chemiluminescent analyzer and sampling method of sampling device

The invention provides a sampling device of a full-automatic chemiluminescent analyzer and a sampling method of the sampling device. The chemiluminescent analyzer comprises a sampling needle system, areagent needle system, a sample area, an injection area and a reagent area, wherein the sample area, the injection area and the reagent area are sequentially arranged from left to right; the samplingneedle system and the reagent needle system are fixed on a same transverse guide track; a reaction cup area perpendicular to the injection area is arranged between the reagent area and the sample area; needle cleaning devices are respectively arranged between the sample area and the injection area and the reagent area and the injection area; sampling positions of the sample area, the injection area, the reagent area and the two needle cleaning devices are on a same straight line; a sampling needle passes through sampling positions of the sample area and the injection area; a reagent needle passes sampling positions of the reagent area and the injection area. According to the sampling device of the full-automatic chemiluminescent analyzer and the sampling method of the sampling device, thesampling positions, the injection positions, grooves and a cleaning area are positioned on a same straight line, so that the injection speed is increased; the sampling positions and the injection positions are fixed, so that the error probability is reduced.

Owner:天津博硕科技有限公司

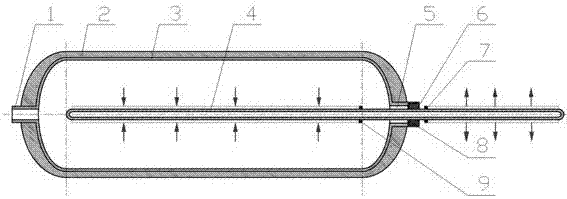

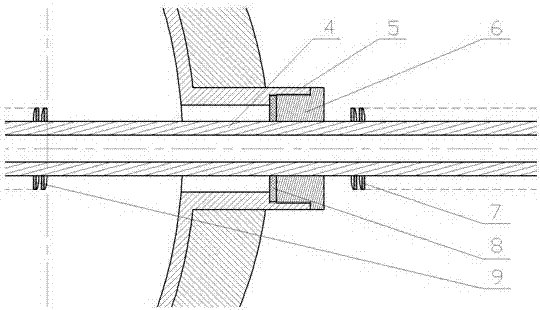

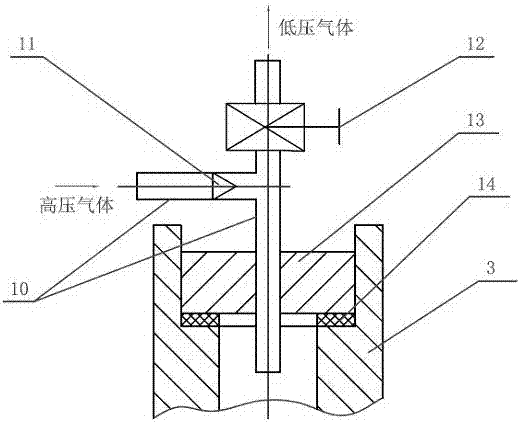

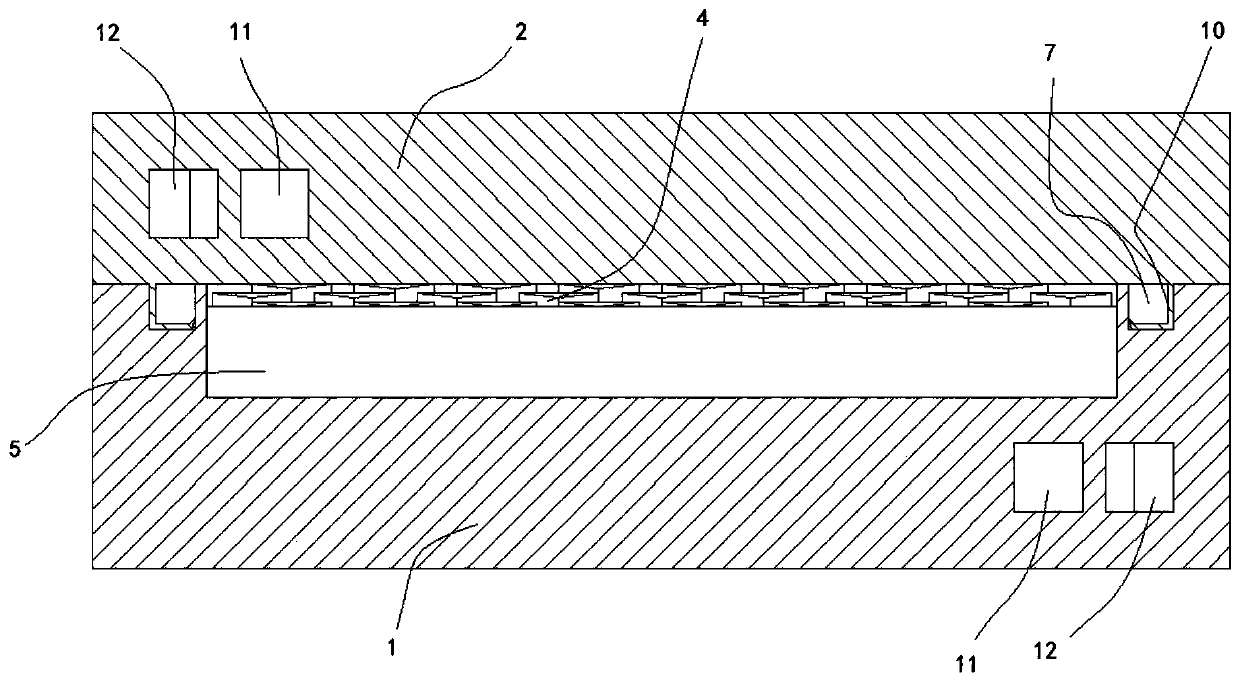

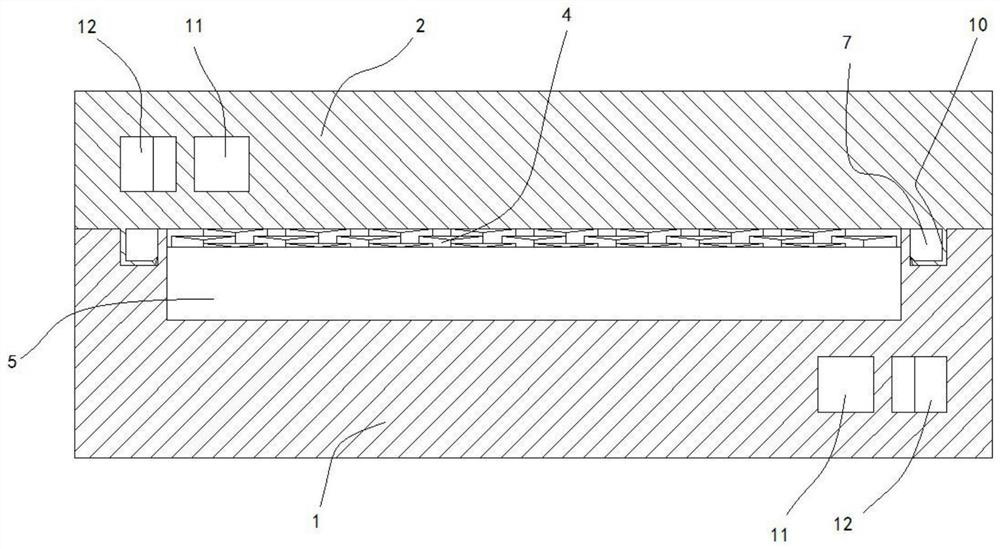

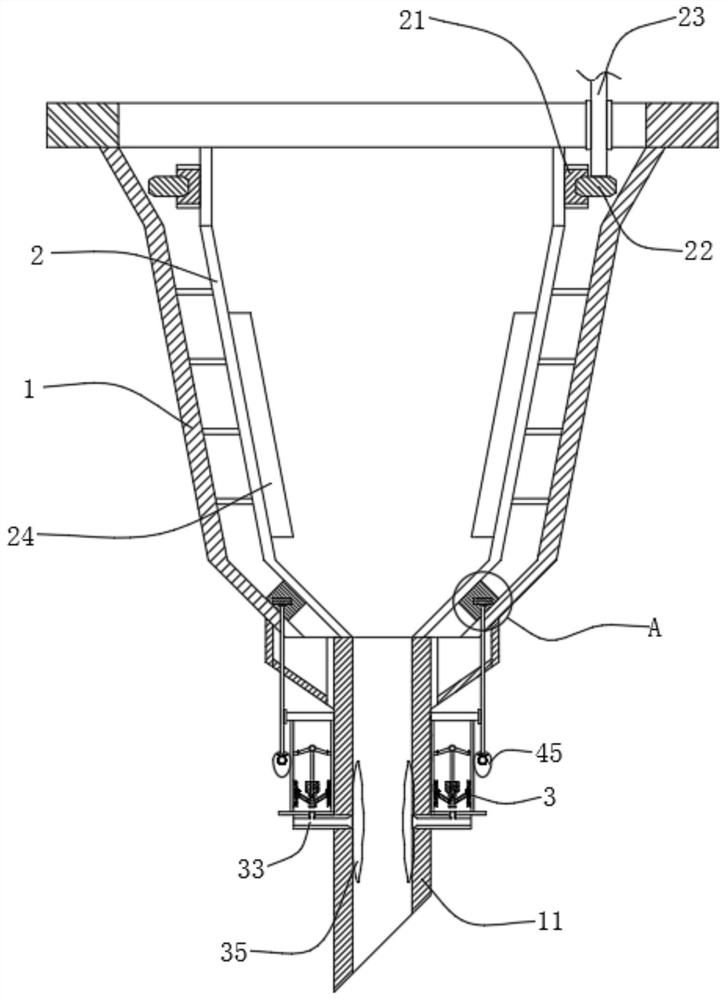

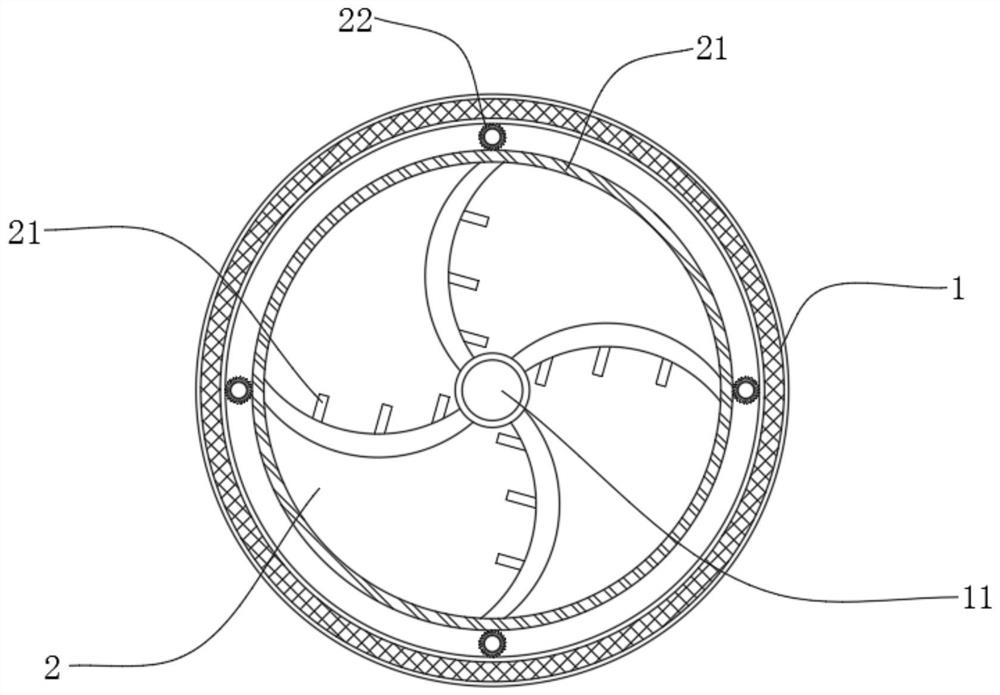

Fiber reinforced composite material high-pressure gas bottle with superconduction radiating device

InactiveCN106895253AReduce energy consumptionIncrease filling rateVessel mounting detailsVessel wallsGas cylinderFilling rate

The invention discloses a fiber reinforced composite material high-pressure gas bottle with a superconduction radiating device. One end of the high-pressure gas bottle is provided with a gas in-out opening, the other end of the high-pressure gas bottle is provided with an opening, one end of a superconduction heat pipe is inserted into the high-pressure gas bottle, the other end of the superconduction heat pipe is located outside the high-pressure gas bottle, fins are arranged outside the superconduction heat pipe, and an inorganic salt superconduction medium is inflated into the pipe; the first end of a three-way pipe penetrates a center hole of a gas in-out opening end cap to be inserted into the high-pressure gas bottle through a front sealing gasket, the second end of the three-way pipe is provided with a high-pressure gas inlet through a one-way valve, and the third end of the three-way pipe is provided with a low-pressure gas outlet through a reducing valve. Or only one end of the high-pressure gas bottle is provided with the gas in-out opening, and one end of the superconduction heat pipe penetrates the center hole of the gas in-out opening end cap to be inserted into the high-pressure gas bottle through the front sealing gasket. In the air inflation process of the fiber reinforced composite material high-pressure gas bottle, measures such as precooling are not needed, and energy consumption is reduced; under the same temperature limitation, the higher filling rate can be achieved; and compared with existing metal tube radiators and heat pipe radiators at home and abroad, the radiating speed is higher, and adaptability is wider.

Owner:ZHEJIANG UNIV

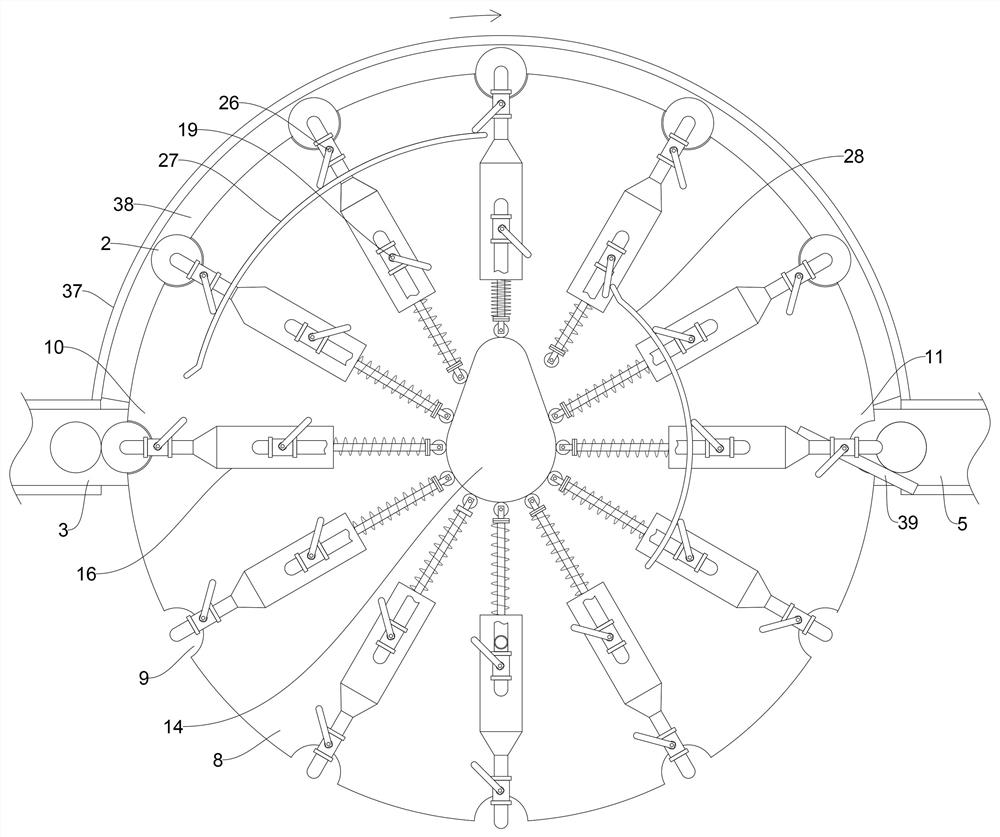

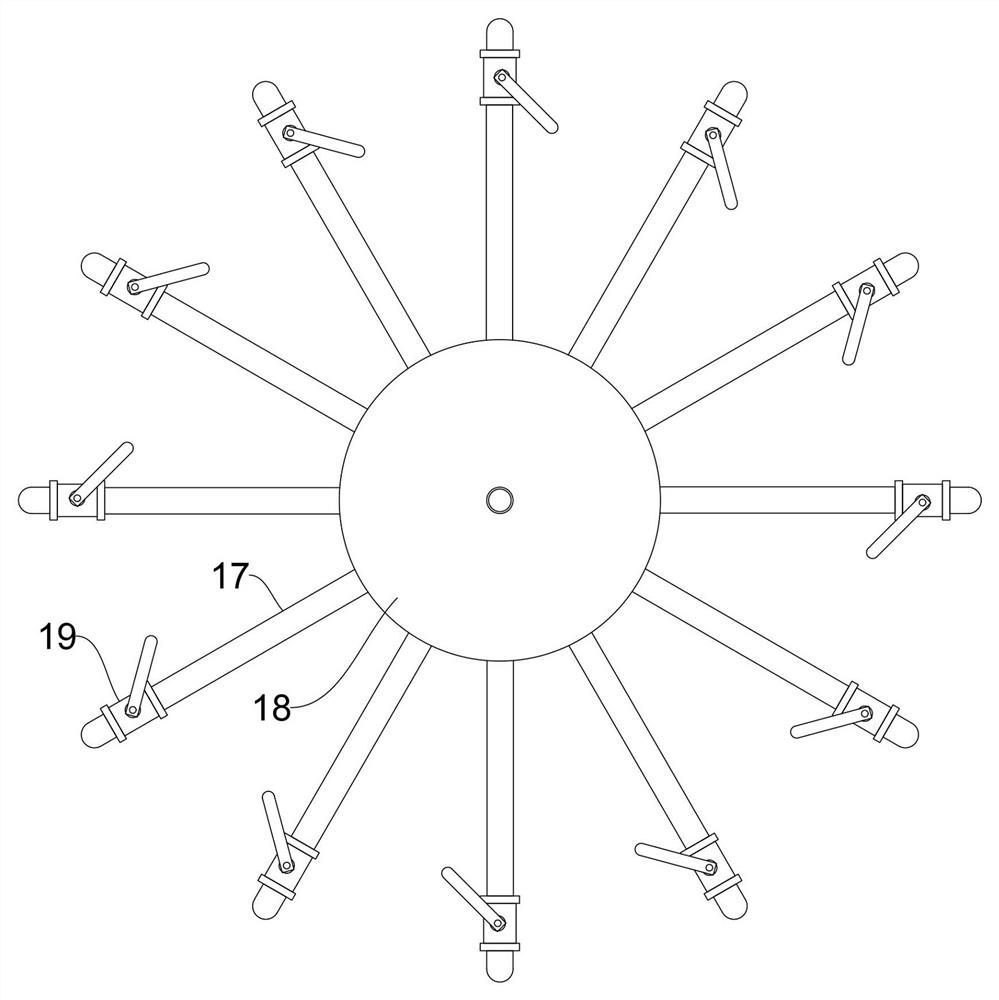

Automatic bottled chili sauce filling device

The invention discloses an automatic bottled chili sauce filling device. The automatic bottled chili sauce filling device comprises a filling table, bottle bodies used for containing chili sauce, an empty bottle conveying belt used for conveying empty bottle bodies to a feeding station, sauce containing tanks used for storing the chili sauce and a sauce bottle conveying belt used for outputting the full-loaded chili sauce bottle bodies, wherein the filling table is provided with a hollow electric turntable, the hollow electric turntable is provided with a filling turntable, and the filling turntable is clamped with the bottle bodies at the feeding station through notches at the edges of the filling turntable, and the bottle bodies filled with the chili sauce are output to the sauce bottleconveying belt at a discharging station; quantitative sauce bins corresponding to the notches in one-to-one correspondence are fixed on the filling turntable through a fixing frame, a distributing pipe is communicated with the upper end of the middle of each quantitative sauce bin, a rotary distributing bin is communicated with the other ends of the distributing pipes, and a feeding mechanism forconveying the chili sauce in the sauce containing tanks to the rotary distributing bin is further included. According to the automatic bottled chili sauce filling device, quantitative material distribution and quantitative filling can be carried out in the moving process of the bottle bodies, and the filling rate can be obviously improved.

Owner:河北世轩科技有限公司

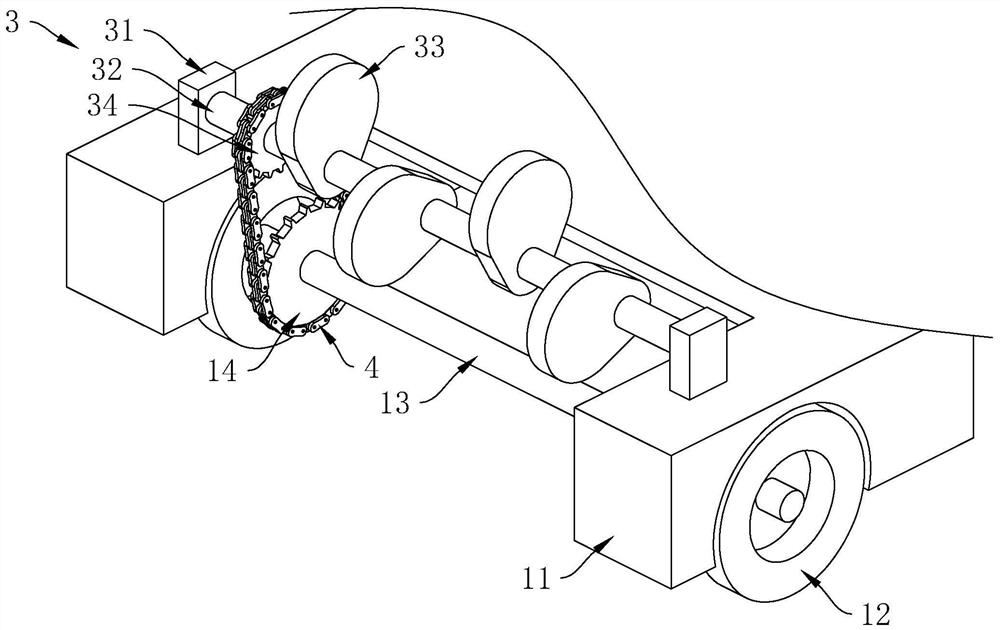

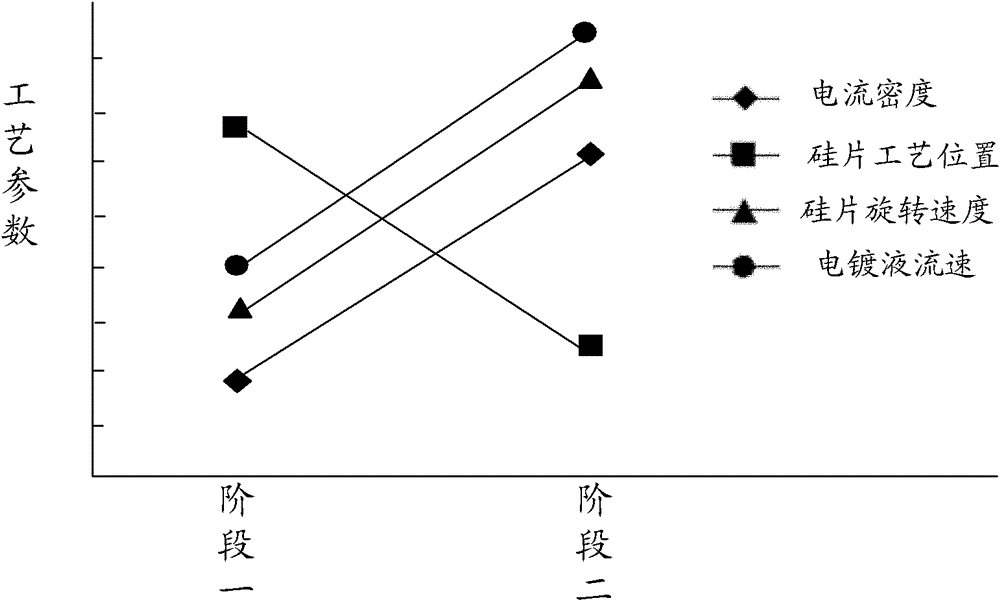

Electrocoppering method

InactiveCN107858715AReduce corrosionReduce thicknessSemiconductor devicesCopper platingProcess conditions

The invention discloses a copper electroplating method, which comprises the following steps: the first step, before the chemical electroplating process of the chip, the wafer groove is ultrasonically oscillated or flushed with deionized water to fill it with deionized water; the second step, Prepare the electroplating solution, the third step, the initial condition electroplating, the transition stage electroplating, and the final stage electroplating, set different parameters respectively. The present invention is used to form copper plating film on integrated circuit graphics with large size and depth, and conducts electroplating process step by step under different current density, silicon chip rotation speed, electroplating solution flow rate and silicon chip process position conditions, reducing the cost of electroplating process The required copper film thickness is shortened, thereby shortening the electroplating process time and chemical mechanical polishing process time, and saving the use of chemical consumables.

Owner:王衍春

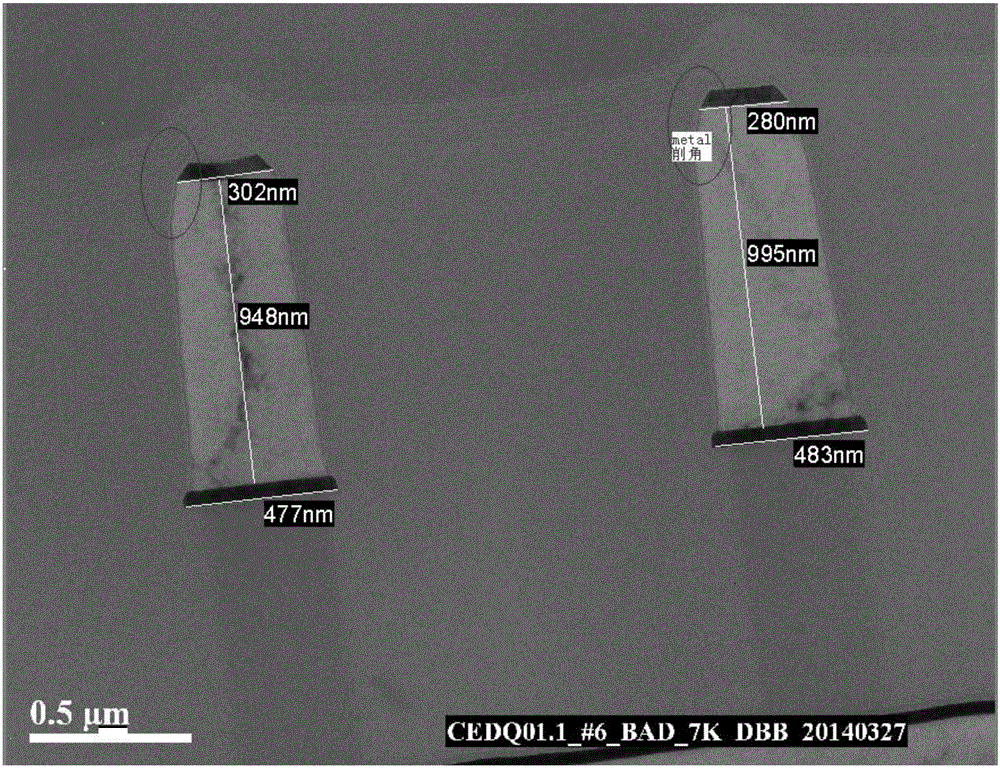

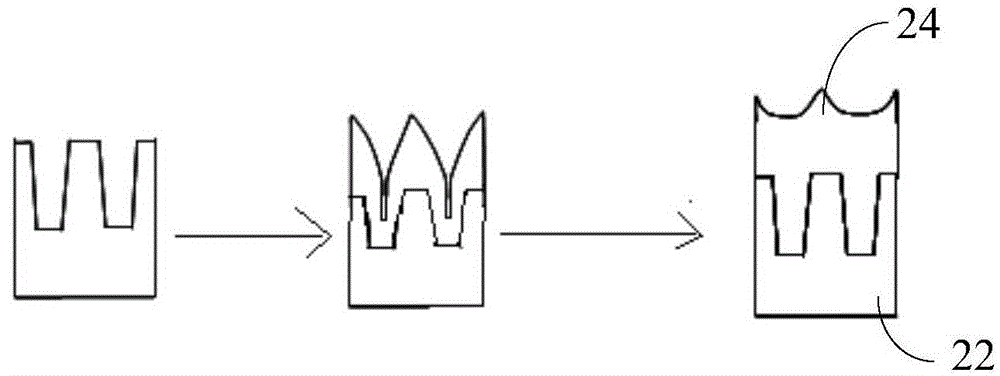

Formation method and HDPCVD method for metal interlay dielectric film layer

InactiveCN106328582AImprove chamferingLow costSolid-state devicesSemiconductor/solid-state device manufacturingDeposition processDielectric

The invention relates to a formation method and an HDPCVD method for a metal interlay dielectric film layer. The HDPCVD method for the metal interlay dielectric film layer adopts a two-step deposition process; a deposition sputtering ratio D / S in the first-step deposition is smaller than the D / S in the second-step deposition; in the first-step deposition, the D / S is 2.1-3.5; the power is 2,800-3,200W; the gas flow is as follows: 100-120sccm of argon, 80-100sccm of oxygen, and 40-50sccm of SiH<4> and SiF<4> altogether; in the second-step deposition, the D / S is 5.1-7.5; the power is 2,300-2,700W; and the gas flow is as follows: 100-120sccm of argon, 160-190sccm of oxygen, and 80-90sccm of SiH<4> and SiF<4> altogether. The HDPCVD method adopts the two-step deposition process; the second-step deposition adopts relatively low power; meanwhile, the gas flow is regulated to enable the environment of an overall deposition chamber to change, thereby obviously relieving a metal angle-cutting phenomenon; meanwhile, relatively low RF power is adopted in the second-step deposition to reduce a bombardment effect, so that the deposition rate in the second-step deposition is increased, thereby improving filling rate while lowering HDP cost; and in addition, the tape-out time of a product can be obviously shortened while the capacity can be improved.

Owner:CSMC TECH FAB2 CO LTD

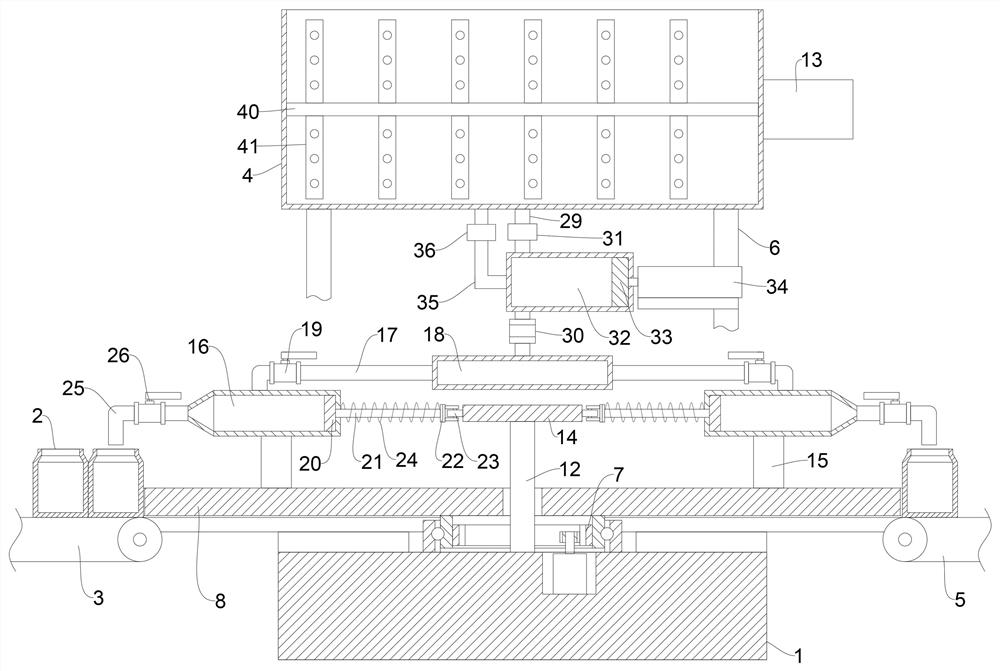

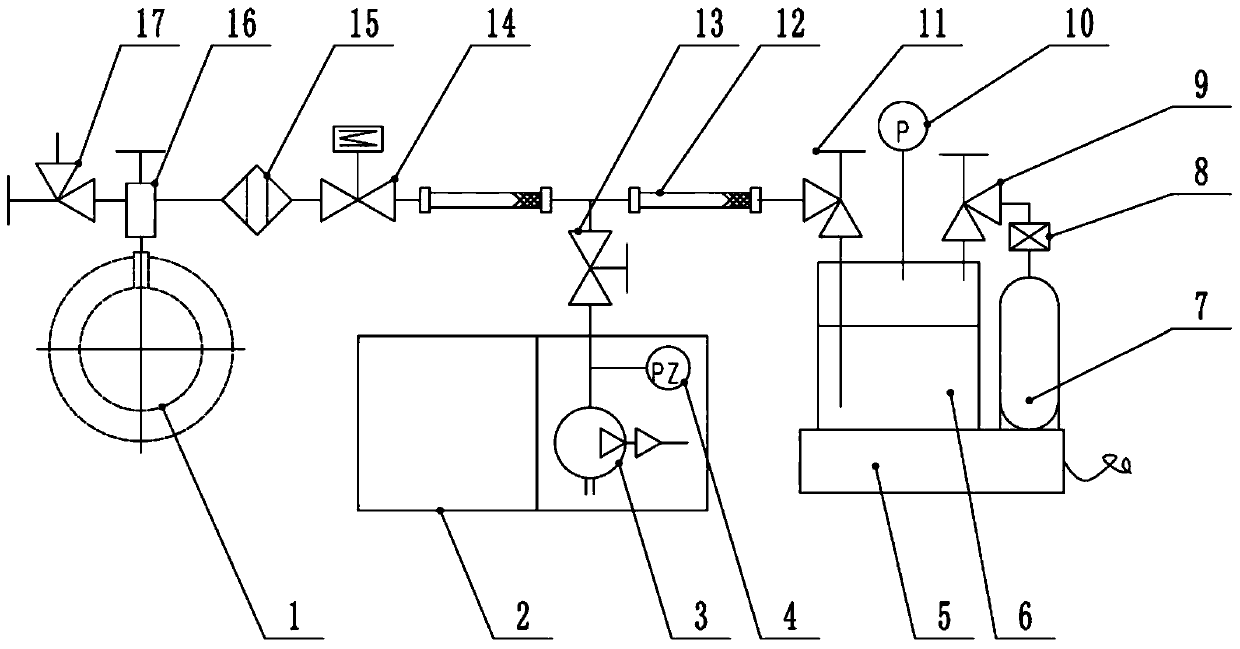

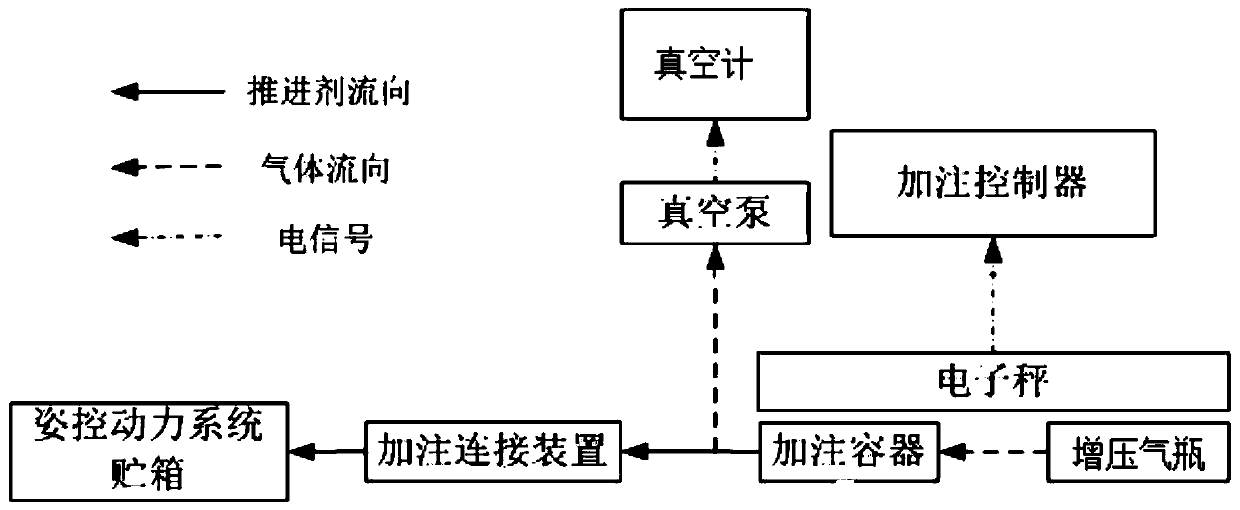

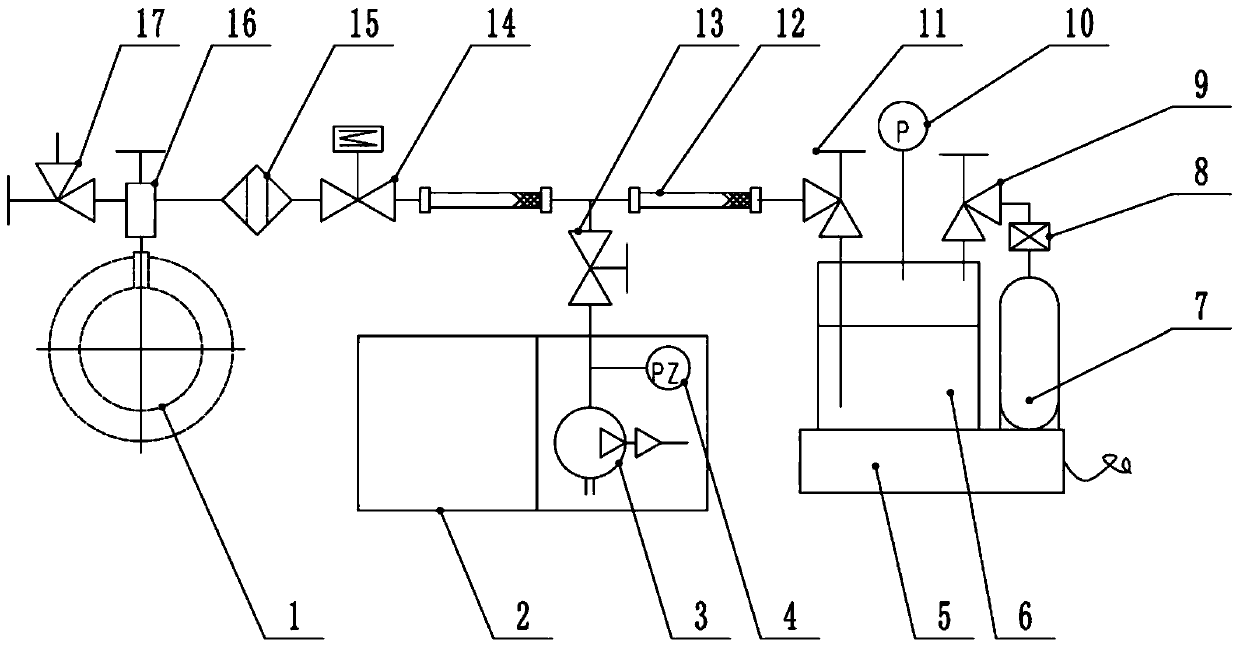

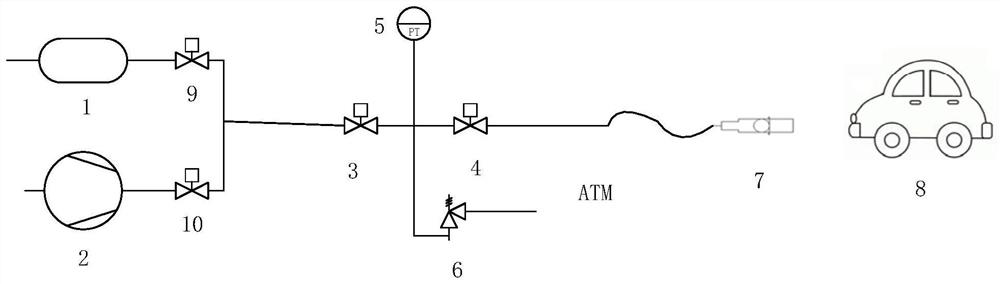

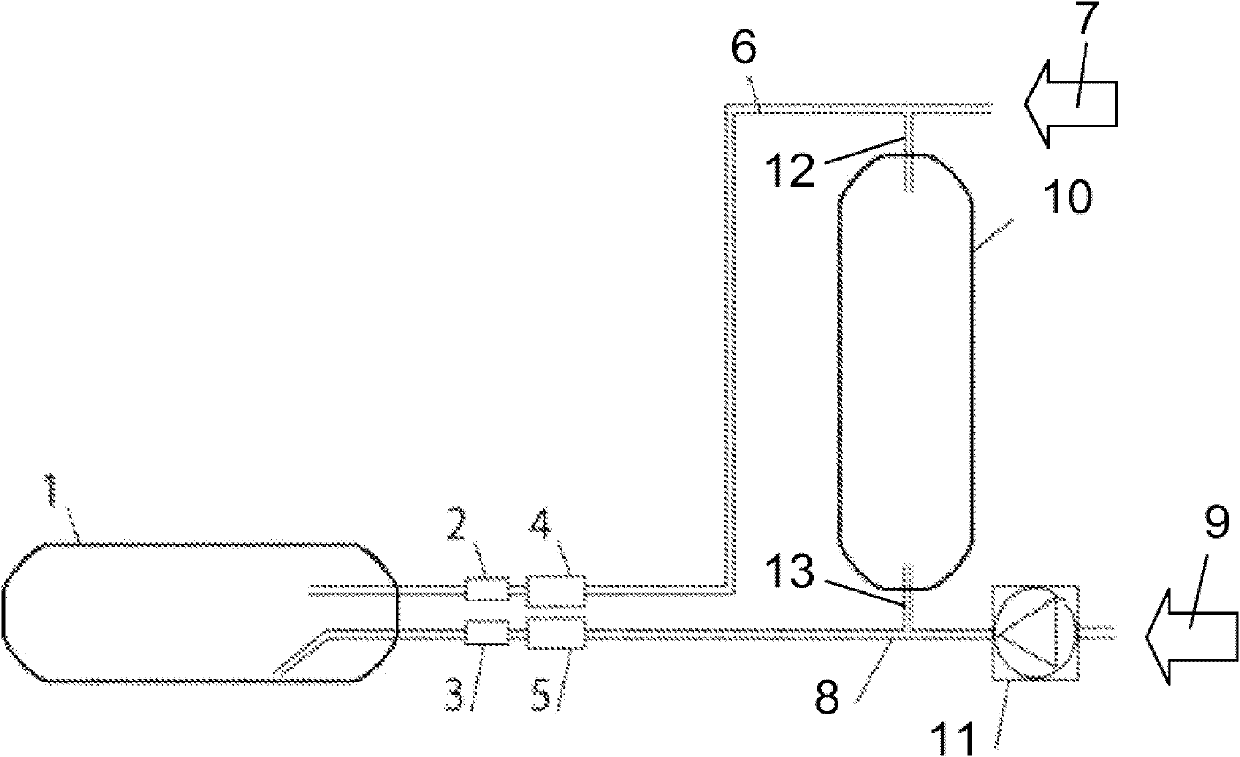

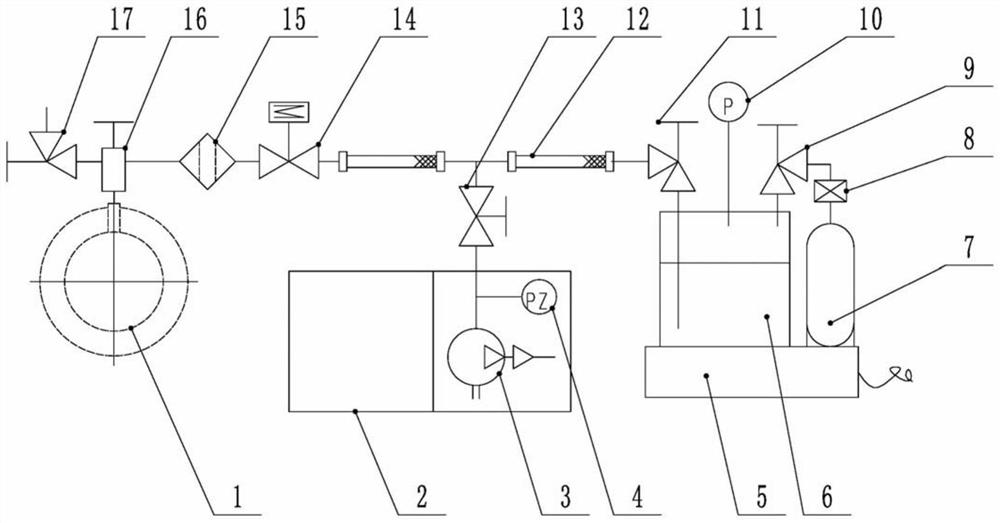

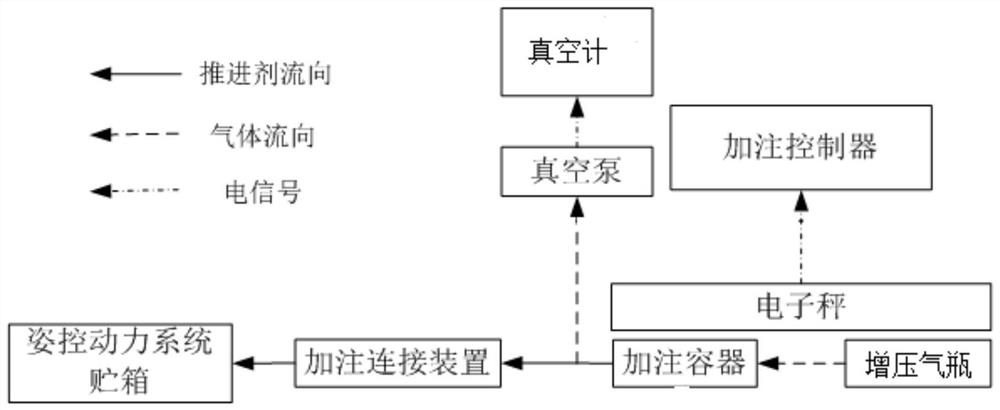

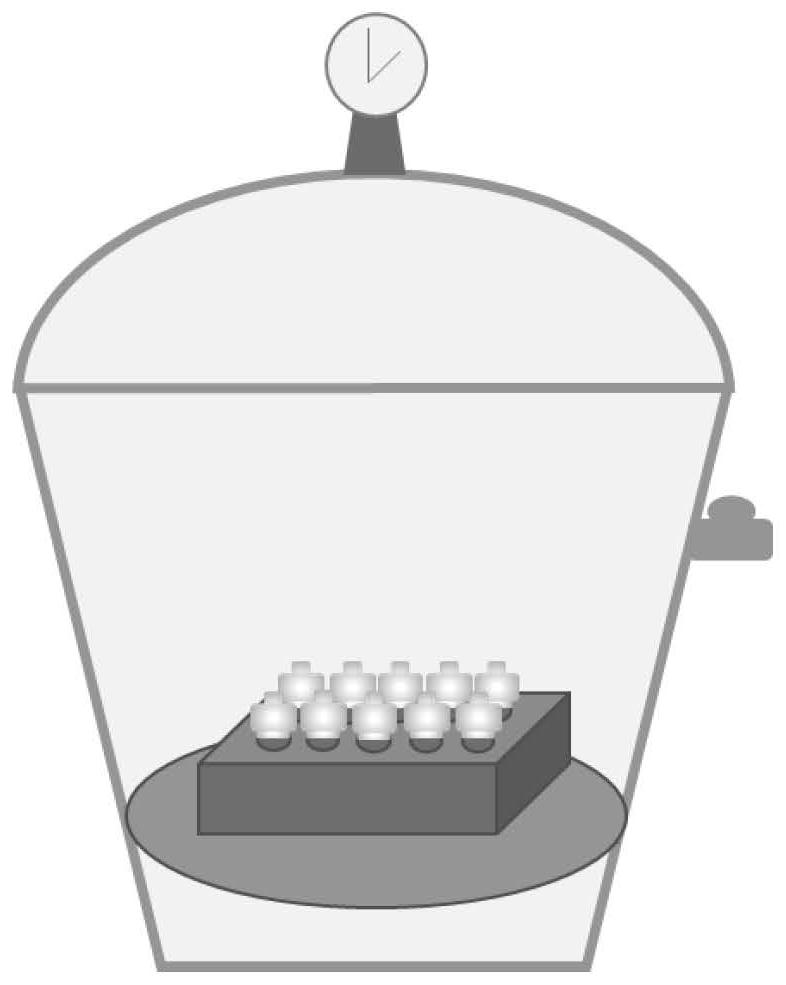

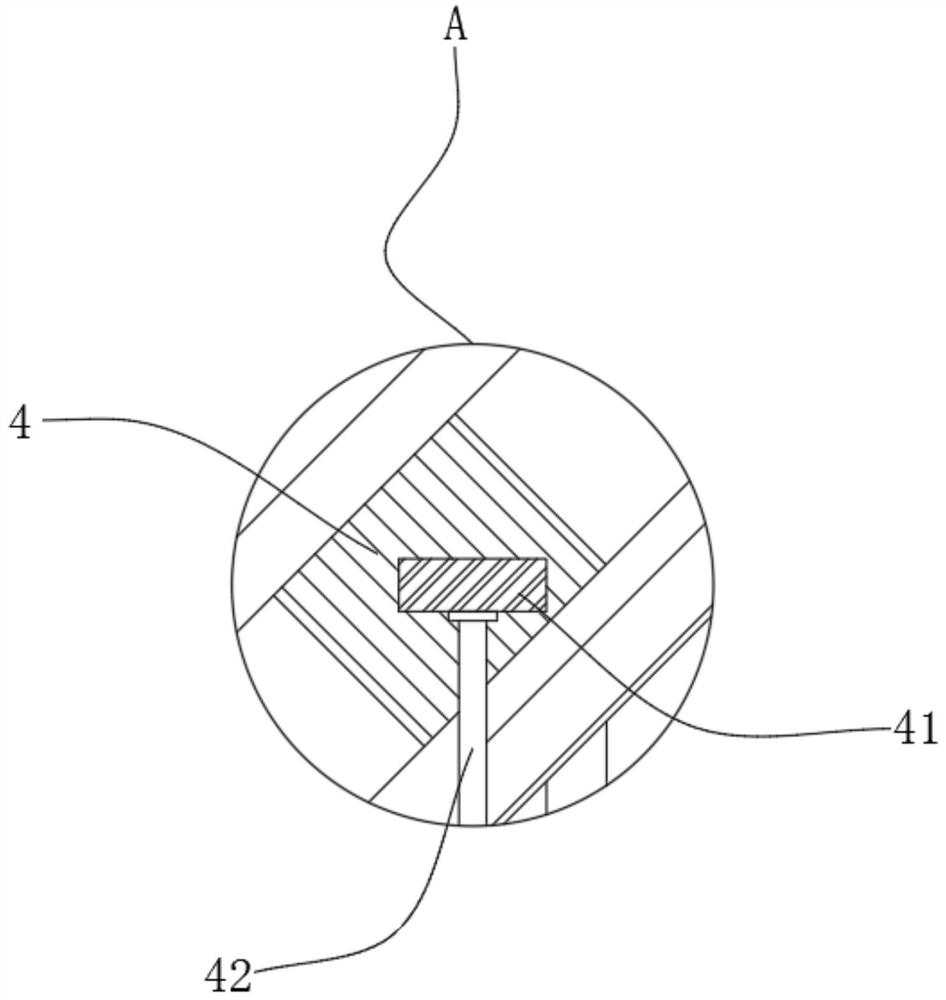

Quantitative charging device and method of attitude control power system

ActiveCN109708896AImprove filling accuracyIncrease filling rateGas-turbine engine testingJet-propulsion engine testingAttitude controlVoltage

The invention relates to a quantitative charging device and method of an attitude control power system, and solves the problem of deviation caused by the charging precision of a present charging system. The device comprises a charging console, a vacuum-pumping system, a charging container, an electronic scale, a voltage stabilization system, a charging connector and a charging pipeline; the charging pipeline comprises a conveying pipe, a metal hose, a charging isolating valve, a filter and a charging solenoid valve; one end of the conveying pipe is connected with a tank of the attitude controlpower system via a charging connector, and the other of the conveying pipe is connected with the metal hose; the end, connected with the charging connector, of the charging pipe is provided with a tapping valve; the vacuum-pumping system comprises a vacuum pump, a vacuum pipe and a vacuum gauge; one end of the vacuum pipe is connected with the vacuum pump, and the other end of the vacuum pipe iscommunicated with the charging isolating valve; the voltage stabilizing system comprises an pressurized air bottle, both the charging container and the pressurized air bottle are arranged on the electronic scale, and the pressurized air bottle is communicated with the charging container; and the charging container is communicated with the conveying pipe of the charging pipe via the tapping valve of the charging container.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

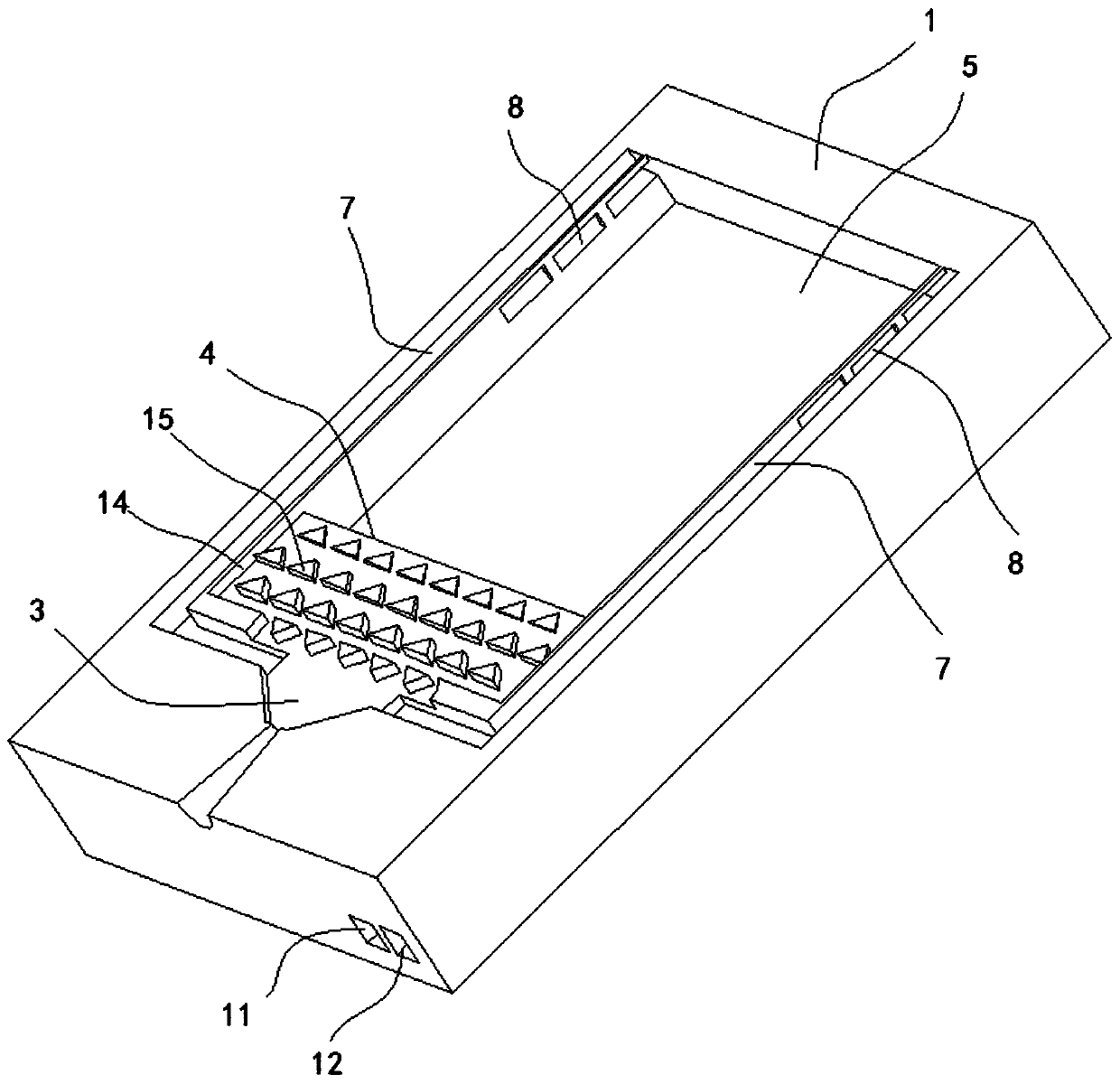

PVC foaming plate extrusion die

The invention discloses a PVC foaming plate extrusion die, and relates to the technical field of foaming plate extrusion dies. The PVC foaming plate extrusion die comprises a lower die plate and an upper die plate matched with the lower die plate, a flow-division buffer zone, a flow equalization zone and a forming die groove are arranged at the upper surface of the lower die plate in a mode of sequentially communicating with a feeding port, wherein the flow-division buffer zone comprises a buffer groove, a pair of L-shaped guide grooves communicating with the buffer groove are symmetrically formed at the positions, located on the two sides of the buffer groove, of the upper surface of the lower die plate, rectangular flow guide holes are linearly arranged on the opposite side surfaces of the pair of L-shaped guide grooves and at the ends, away from the flow-division buffer zone, of the pair of L-shaped guide grooves, a T-shaped flow guide groove communicating with the feeding port is formed in the lower surface of the upper die plate, the T-shaped flow guide groove communicates with the buffer groove and the pair of L-shaped guide grooves correspondingly, and a pair of L-shaped connection guide grooves are symmetrically fixed on the lower surface of the upper die plate. According to the PVC foaming plate extrusion die, through the lower die plate and the upper die plate which are designed, a foaming material enters the forming die groove in three directions, a PVC foaming plate is easier to form rapidly, so that the problem that the efficiency is low when an existing die isused for forming the PVC foaming plate is solved.

Owner:合肥帝品数码科技有限公司

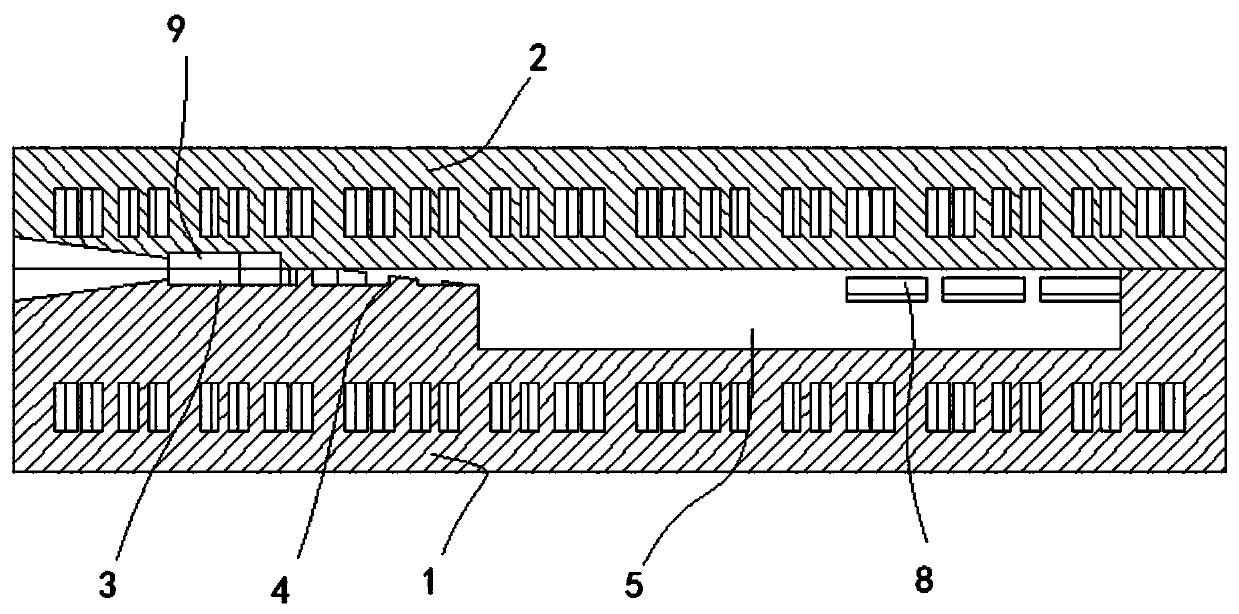

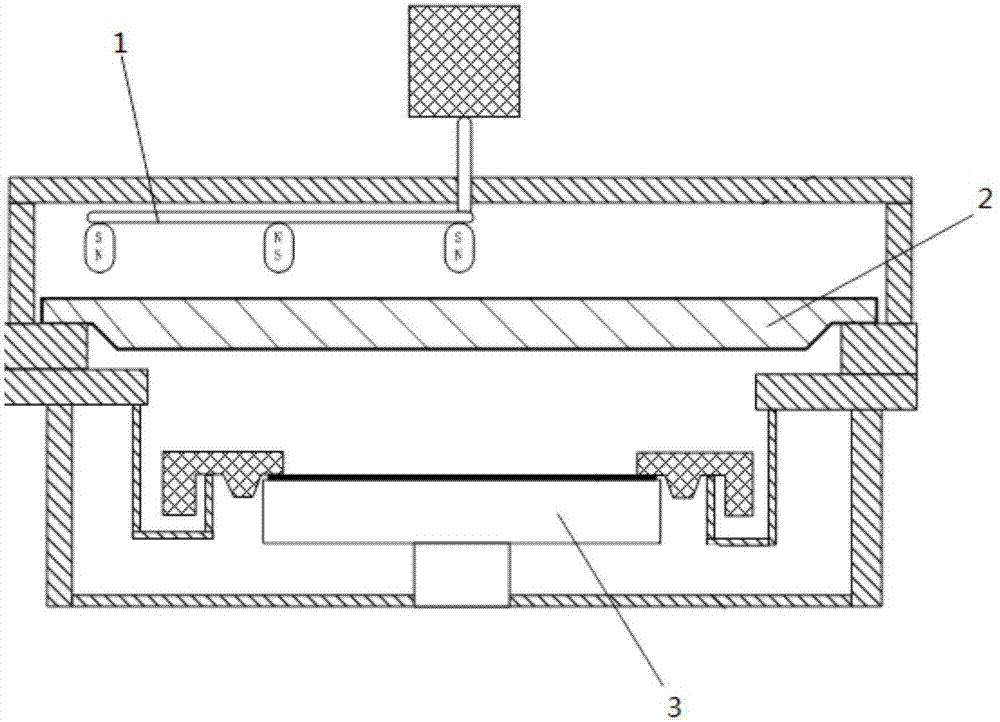

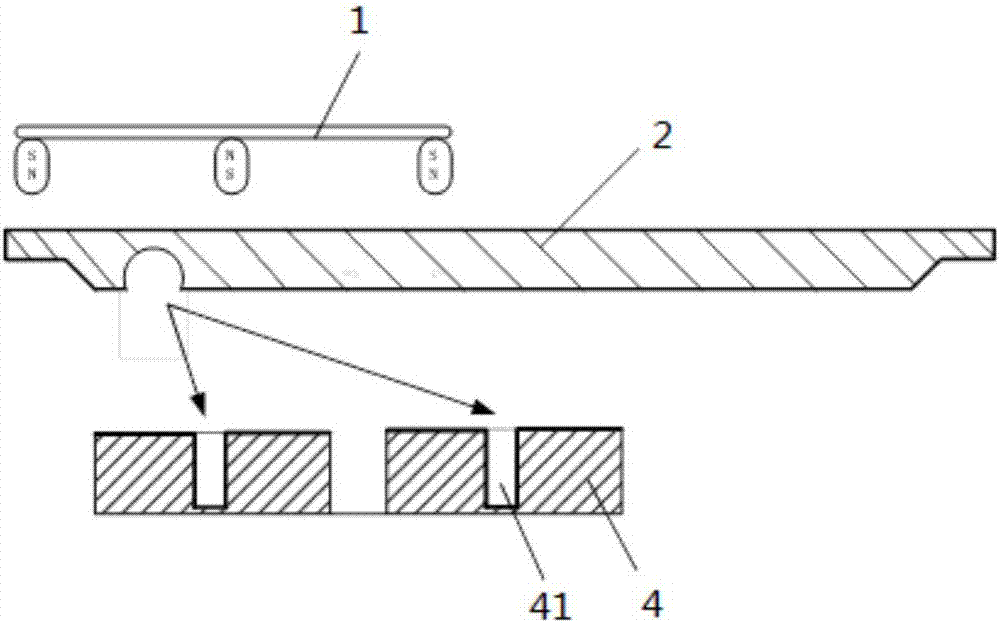

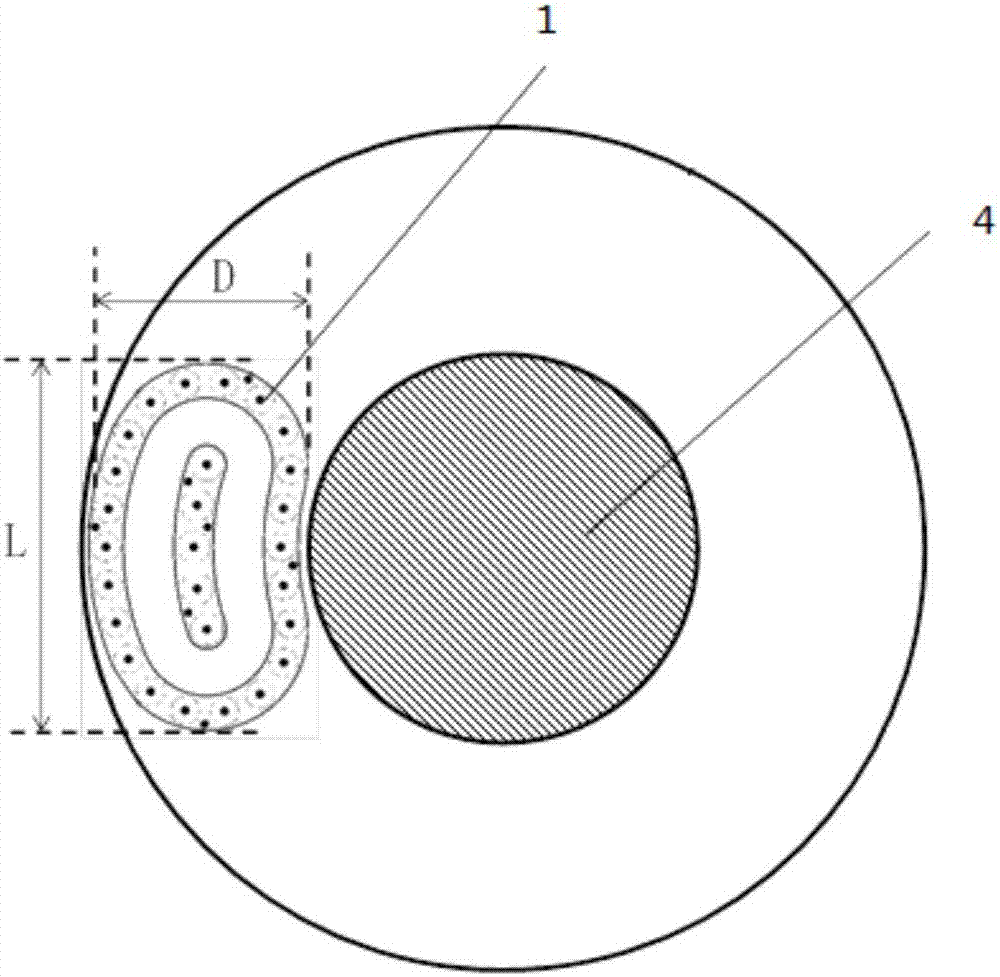

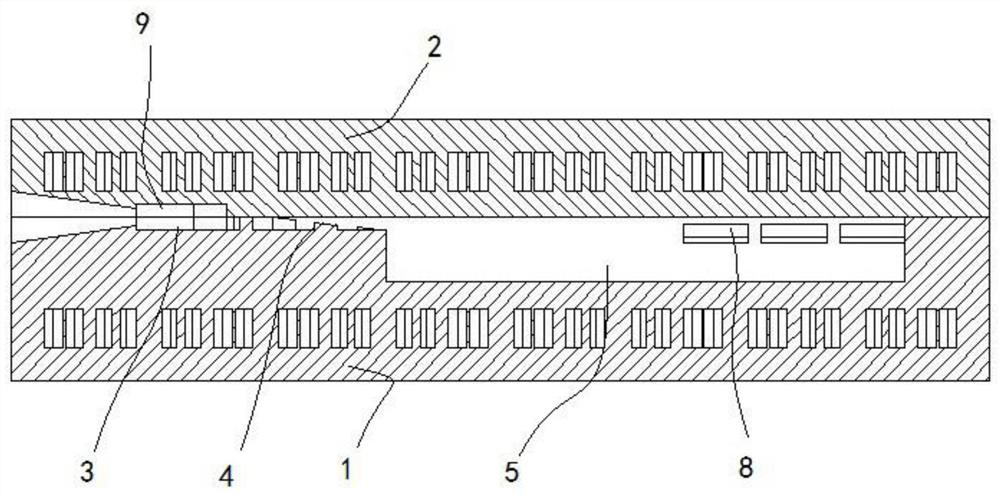

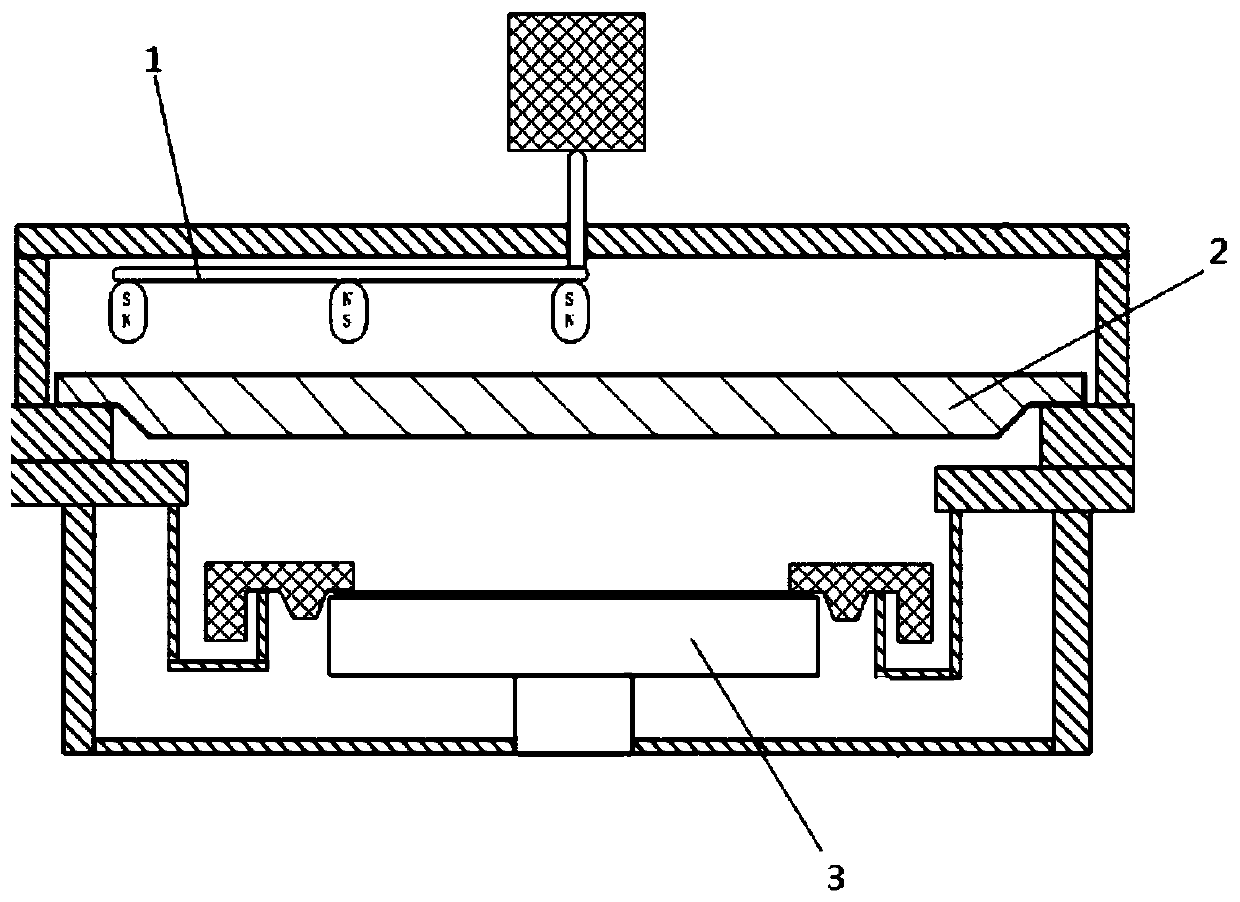

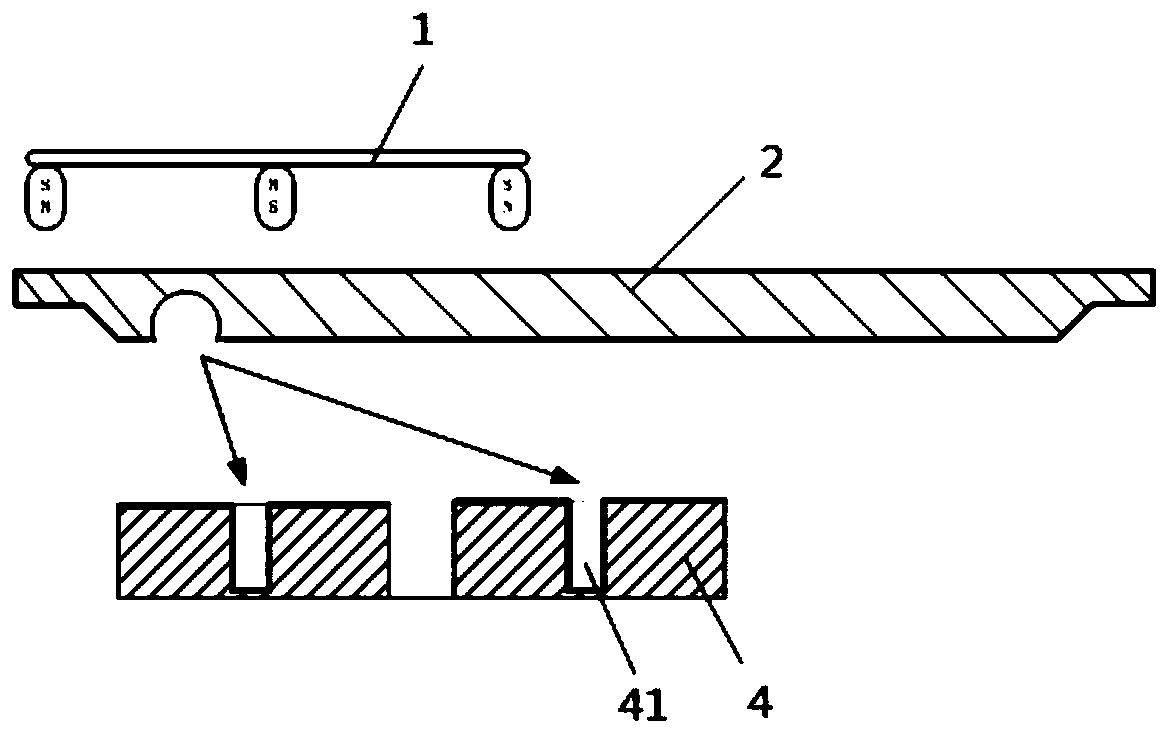

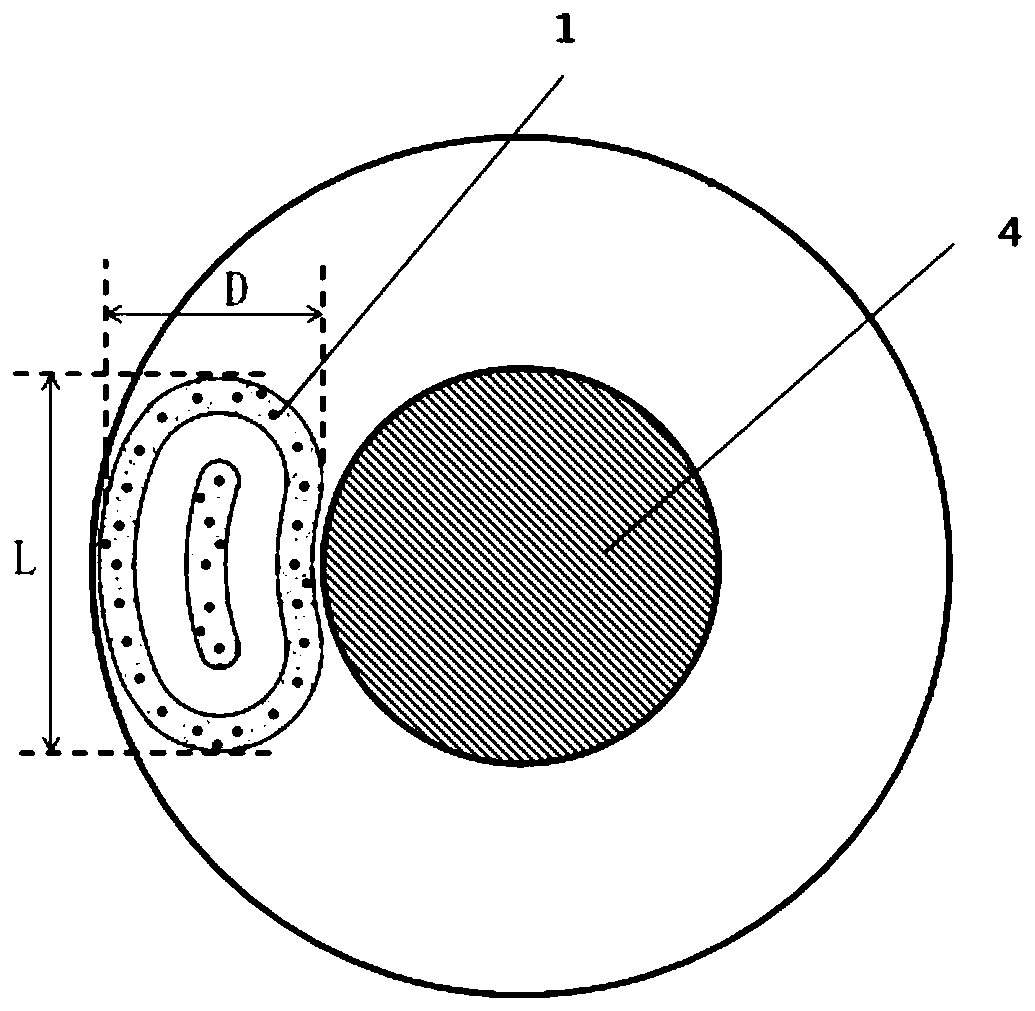

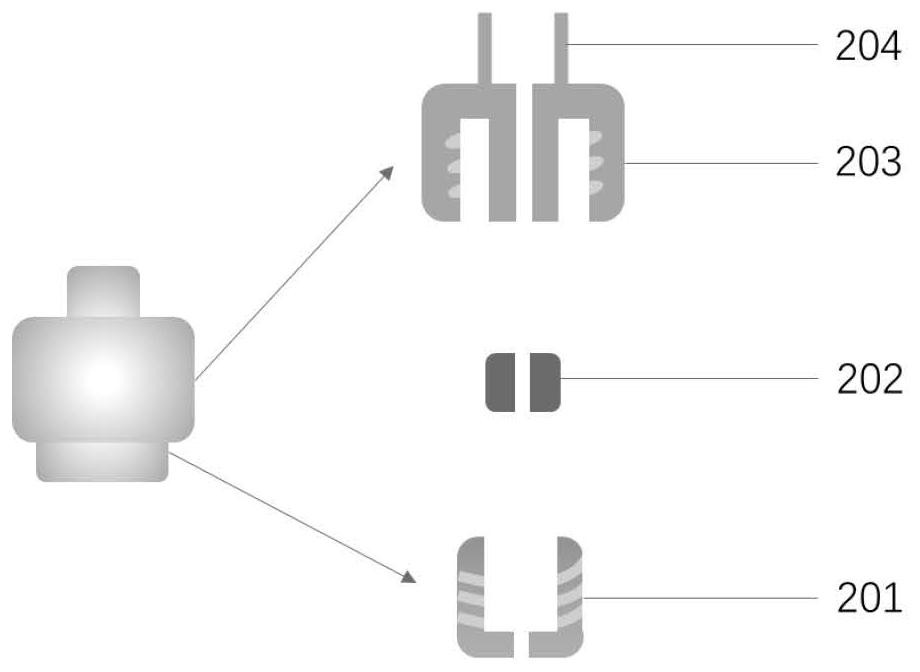

Magnetron sputtering cavity and semiconductor processing device for silicon through hole filling

ActiveCN107068599AIncrease filling rateIncrease ionization rateVacuum evaporation coatingSputtering coatingFilling rateIonization

The invention discloses a magnetron sputtering cavity and a semiconductor processing device for silicon through hole filling. The magnetron sputtering cavity comprises a cavity, a target material arranged on the top of the cavity, a magnetron arranged above the target material and a base which is arranged inside the cavity and under the target material; a projection area of the magnetron on the target material is smaller than one fifth of the area of the target material in order to improve an ionization rate of a medium gas so as to improve a filling rate for the silicon through hole. The semiconductor processing device comprises the magnetron sputtering cavity. The magnetron sputtering cavity and the semiconductor processing device improve filling efficiency of the silicon through hole.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

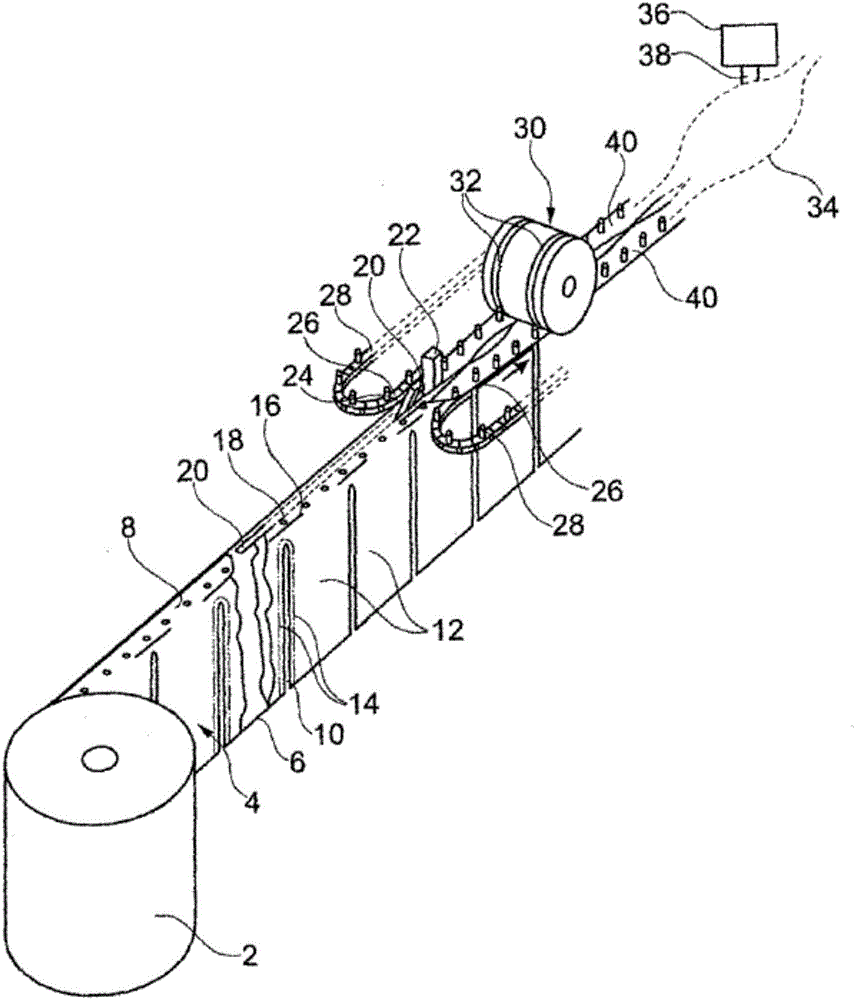

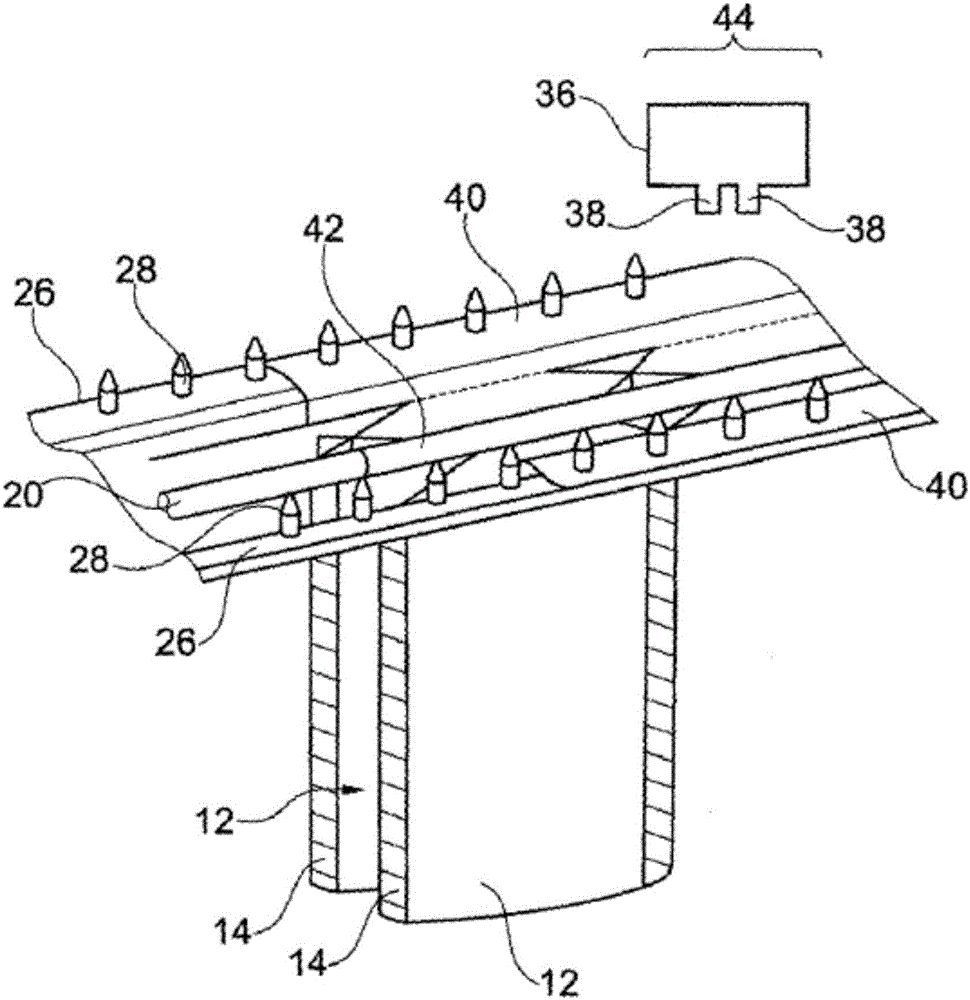

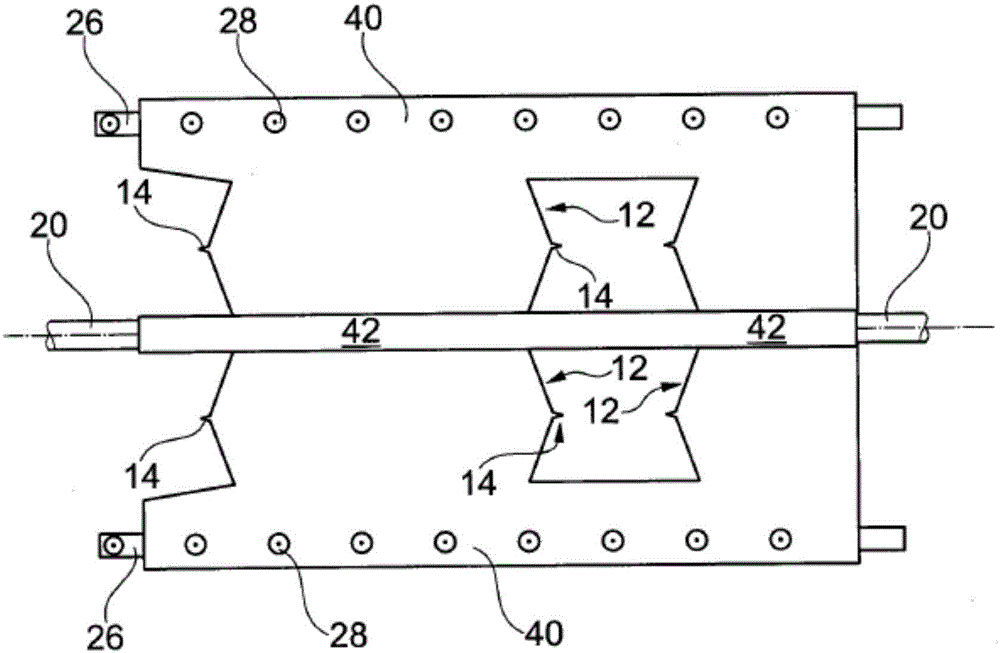

Method and apparatus for packing items, liquid or loose material in film bags, and a bag web

There is disclosed a method for packing articles, liquid or loose material in film bags which are conveyed through a filling station in a continuous web of bag items, wherein the bag openings are kept open for reception of articles, after which the bags are closed and separated from the web. In order to increase the filling rate and make the bags cheaper, the bag web is provided with a central support region extending longitudinally of the bag web and connecting bag items that are disposed side by side transversely of the web. The central support region is conveyed on a support rail along the conveyor path through the filling station and formed as an entirely or partially closed channel. The peripheral areas of the bag items at the outermost opposite bag opening edges of two juxtaposed bag items are brought into guiding connection with guide means adapted for retaining and guiding edge areas at opposing bag opening edges along a conveyor path through the filling station. In connection with this passage, the guide means will force the bag opening edges apart for successive opening of the bags in the filling station, and then, after filling the bags, joining the bag opening edges for closing the bags again.

Owner:SCHUR TECH AS DK

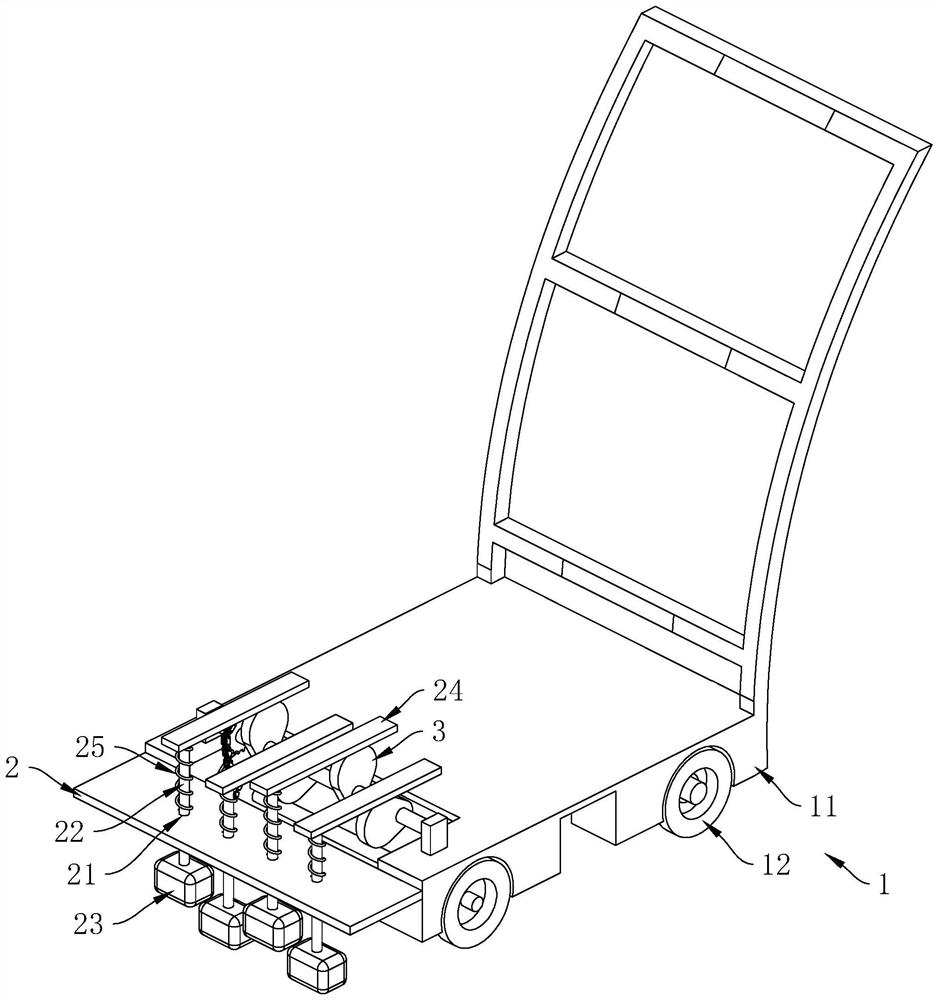

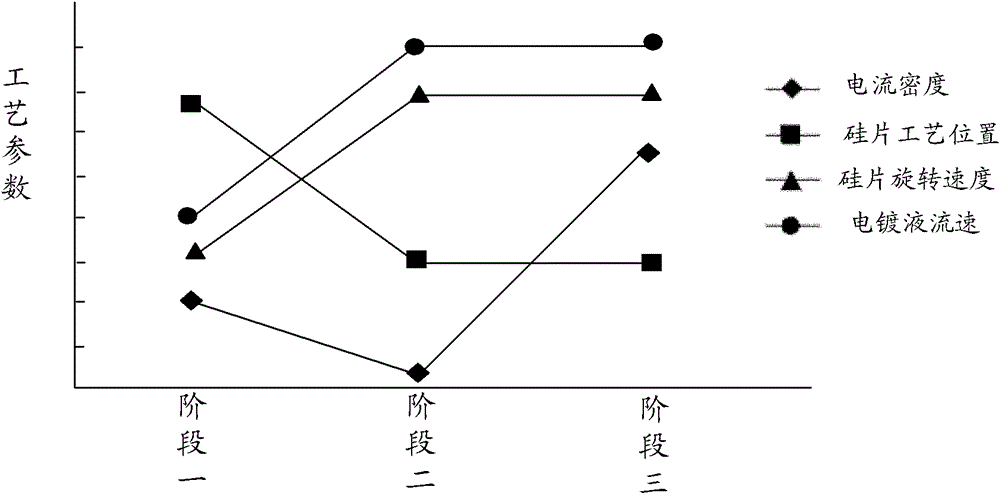

Stage electroplating process copper electroplating method

InactiveCN103806030AHigh fill rateReduce copper film thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesProcess windowPower flow

The present invention relates to a stage electroplating process copper electroplating method, which is characterized in that the method adopts a stage electroplating process and an electroplating solution adapted to the process to treat, wherein the process conditions of each treatment stage in the stage electroplating process treatment comprise that the silicon wafer process position is 2-10 mm, the current density is 0.2-8 A / dm<2>, the silicon wafer rotation speed is 5-50 rotation / min, the electroplating solution flow rate is 4-20 L / min, and the time is 3-500 seconds. According to the present invention, the high filling rate is ensured while the step height of the large size and large depth pattern relative to the unpatterned area is effectively reduced, and the copper film thickness required by the electroplating process is indirectly reduced under the premise of assurance of the chemical mechanical polishing process window so as to shorten the electroplating process time and the chemical mechanical polishing process time, and save chemical material consumption.

Owner:WUXI XINSANZHOU STEEL

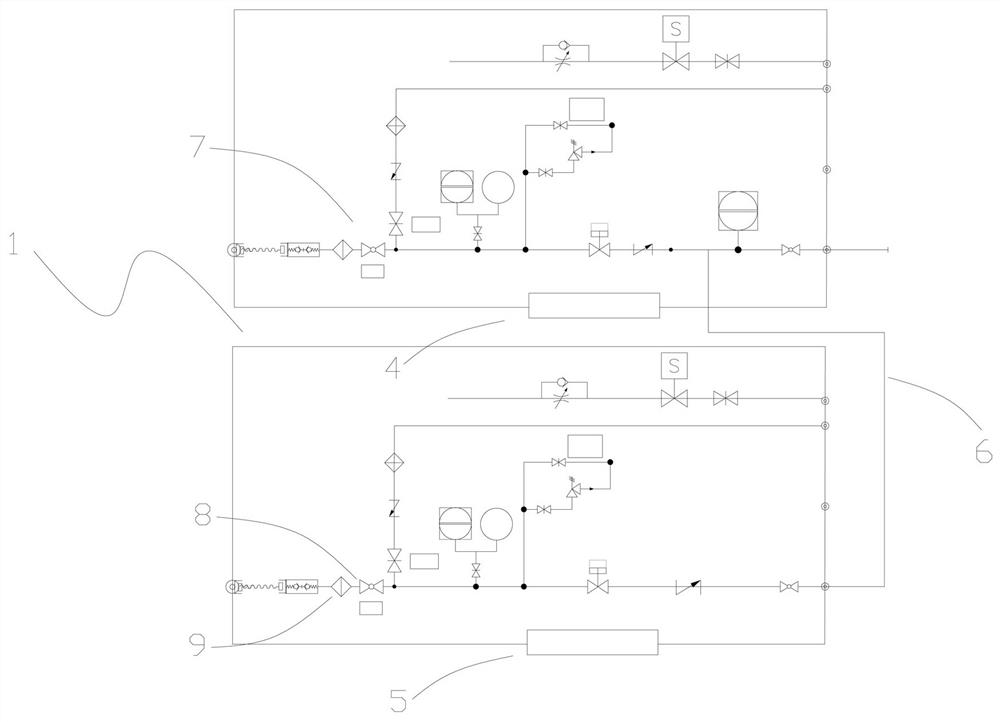

Vehicle-mounted gas cylinder initial pressure measuring device and method for hydrogen refueling station

The invention discloses a vehicle-mounted gas cylinder initial pressure measuring device and method for a hydrogen refueling station. The measuring device comprises a hydrogen source, an inlet pneumatic valve, an outlet pneumatic valve, pressure sensors and a hydrogen refueling gun; the hydrogen source is connected with the hydrogen refueling gun through a pipeline A; the hydrogen refueling gun isused for being connected with a vehicle-mounted gas cylinder of a vehicle to be filled with hydrogen; the inlet pneumatic valve and the outlet pneumatic valve are both installed on the pipeline A, the inlet pneumatic valve is close to the side where the hydrogen source is located, and the outlet pneumatic valve is close to the side where the hydrogen refueling gun is located; the pressure sensorsare installed on the pipeline A and located between the inlet pneumatic valve and the outlet pneumatic valve; and the pressure sensors are used for measuring the air pressure in the pipeline A. According to the vehicle-mounted gas cylinder initial pressure measuring device and method, safety guarantee can be provided for filling of the hydrogen fuel cell vehicle, and the filling speed is increased.

Owner:BEIJING AEROSPACE RATE MECHANICAL & ELECTRICAL ENG CO LTD +1

Novel liquid seasoning filling machine

InactiveCN106744596AIncrease filling rateEasy to introduceBottle-handling machinesLiquid bottlingMachine toolMaterial storage

The invention discloses a novel liquid seasoning filling machine which comprises a material storage tank, a cap sealing machine, a filling machine body, a transferring machine tool, a control panel, a seasoning feeder and a master control cabinet. The material storage tank is welded to the filling machine body in a closed mode. The filling machine body is welded to an underbed of the filling machine through bolts. The master control cabinet is mounted above the underbed of the filling machine. The seasoning feeder is mounted on the right side of the front portion of the filling machine body in a welded mode. The cap sealing machine is mounted on the left side of the front portion of the filling machine body in a welded mode. The transferring machine tool is fixedly mounted on the front portion of the filling machine body through bolts. The control panel is fixed to the right side of the filling machine body through bolts. By adoption of the novel liquid seasoning filling machine, the filling speed of a liquid seasoning is increased, spilling caused by collision in the filling process is avoided, the manual labor cost is reduced, meanwhile, the introduction cost is low, and economic benefits of manufacturers are maximized.

Owner:庄坤达

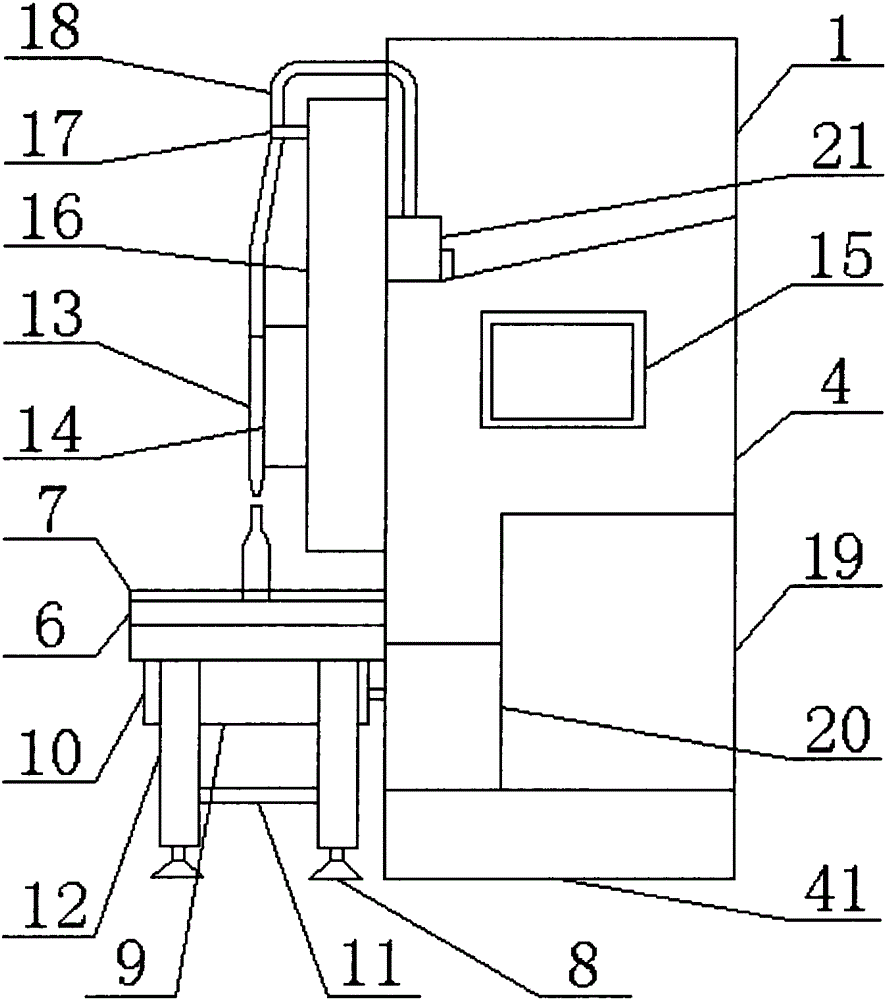

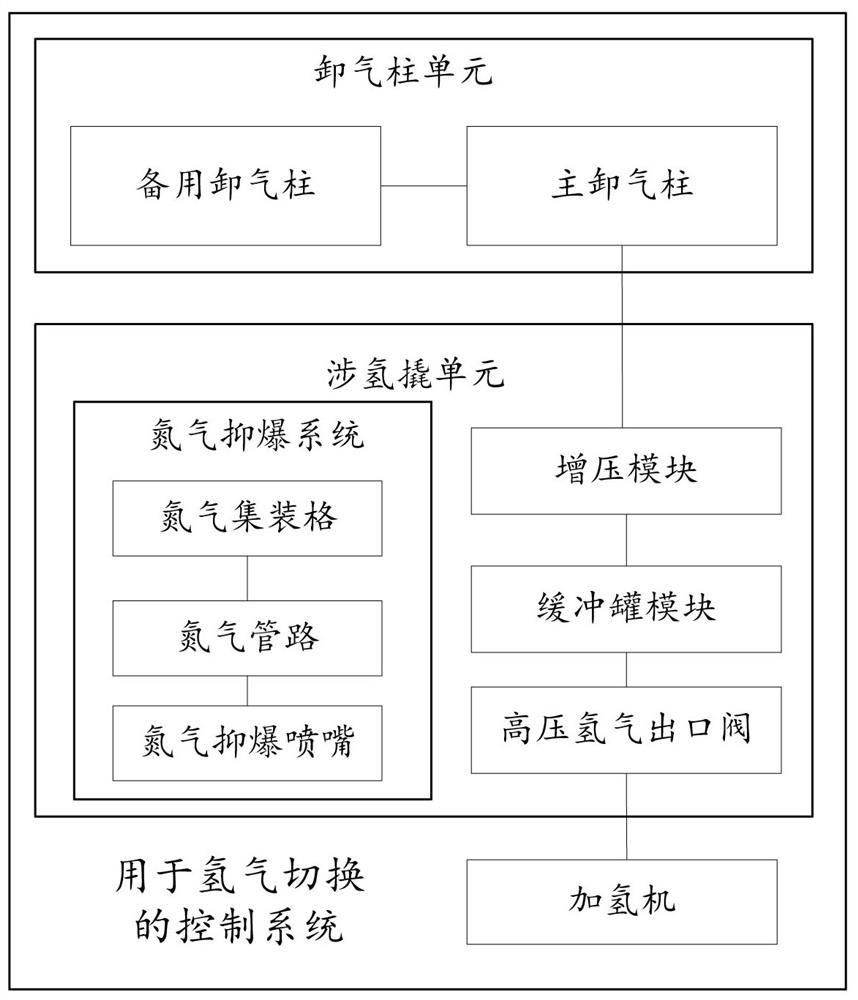

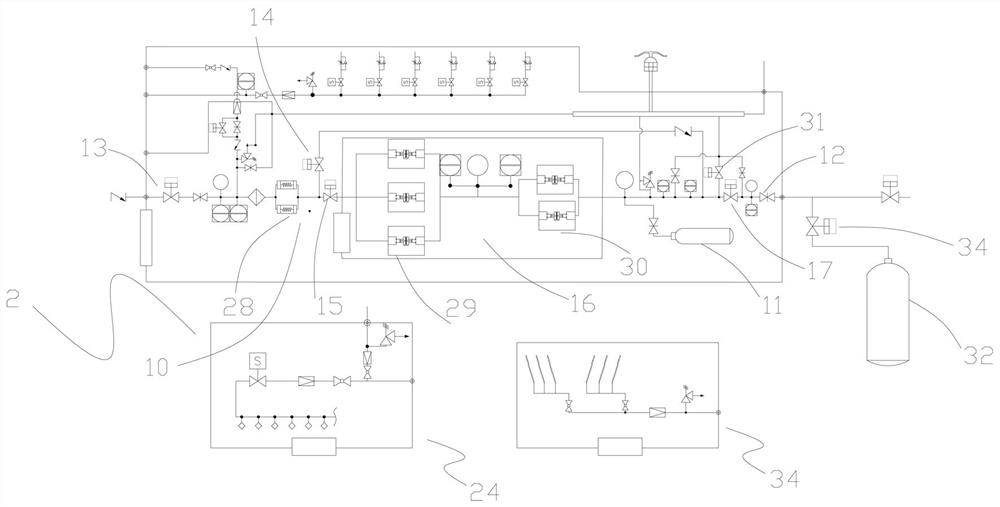

Control system for hydrogen switching

InactiveCN114526443AIncrease filling rateQuick switchVessel mounting detailsFluid transferredThermodynamicsHigh pressure hydrogen

The invention relates to a control system for hydrogen switching, which comprises a gas discharging column unit, a hydrogen related pry unit, a high-pressure hydrogen storage tank and a hydrogen adding machine, the gas discharging column unit comprises a main gas discharging column, a standby gas discharging column and a hydrogen pipeline, and the standby gas discharging column is connected with the main gas discharging column through the hydrogen pipeline, so that the pipelines of the main gas discharging column and the standby gas discharging column are connected; the standby gas discharge column and the main gas discharge column both adopt the mass flow meter on the main gas discharge column, so that the equipment cost is effectively saved. Meanwhile, the main gas discharging column and the standby gas discharging column are connected with the hydrogen pipe bundle type containers through hydrogen hoses, circulation of hydrogen of the main gas discharging column and the standby gas discharging column is controlled through the pipeline control module, and therefore rapid switching between the main gas discharging column and the standby gas discharging column is completed, the two hydrogen pipe bundle type containers serve as low-pressure and medium-pressure gas sources, and the high-pressure and medium-pressure gas sources are used. And a high-pressure hydrogen storage tank in the station is matched, so that the hydrogen utilization rate is improved, the coke soup effect is reduced, and the continuity of the whole set of control system during operation is also ensured.

Owner:浙江浙能航天氢能技术有限公司

Box tofu filling system and method

PendingCN108438280AImprove accuracyPrevent overflowLiquid materialLiquid level measurementEngineering

The invention discloses a box tofu filling system and method. The box tofu filling system comprises a tofu box conveying belt. The conveying belt is sequentially provided with tofu box containing grooves, and a primary soybean milk filling section for injecting soybean milk into tofu boxes, a soybean milk supplementing section and a sealing section are sequentially arranged front and back along the tofu box conveying belt, and the conveying belt carries the tofu boxes to continuously pass through the primary soybean milk filling section, the soybean milk supplementing section and the sealing section at the constant speed, and for a soybean milk supplementing nozzle of the soybean milk supplementing section, a soybean milk supplementing control device is used for controlling opening and closing of the soybean milk supplementing nozzle. Laser liquid level sensors are arranged on the two sides of the production line tofu boxes, non-contact liquid level measurement soybean milk supplementing is achieved, and the problem about cross contamination is solved; the measuring precision of the liquid level sensors is improved, soybean milk filling is not achieved through one-time filling while the secondary soybean milk supplementing manner is adopted, and the soybean milk is prevented from overflowing out of the boxes while it is guaranteed that the boxes are full.

Owner:FOODSTUFF INST BEIJING

Device for controlling hydrogen release efficiency of alloy hydrogen storage equipment

ActiveCN110707344AIncrease filling rateReduce the temperatureFuel cell heat exchangeThermodynamicsFuel cells

The invention discloses a device for controlling hydrogen release efficiency of alloy hydrogen storage equipment. The device comprises a fuel cell, a semiconductor chilling plate, the alloy hydrogen storage equipment and a heat-conducting medium, the alloy hydrogen storage device is connected with the fuel cell through a pipeline, and the cold end and the hot end of the semiconductor chilling plate are connected with the fuel cell and the alloy hydrogen storage device through heat conduction media respectively. The invention has the beneficial effects that when the fuel cell works, the hot endof the semiconductor chilling plate heats and preserves heat of the alloy hydrogen storage equipment through the heat-conducting medium, and the cold end dissipates heat and cools the fuel cell through the heat-conducting medium, so that the alloy hydrogen storage equipment and the fuel cell are kept in a proper temperature interval to achieve the optimal working efficiency; when the alloy hydrogen storage device is filled with hydrogen, the semiconductor chilling plate exchanges the cold end and the hot end by changing the current direction, the cold end cools the alloy hydrogen storage device through the heat conduction medium to improve the hydrogen filling rate, and the hot end takes cooling measures to reduce the temperature of the alloy hydrogen storage device.

Owner:安徽伯华氢能源科技有限公司

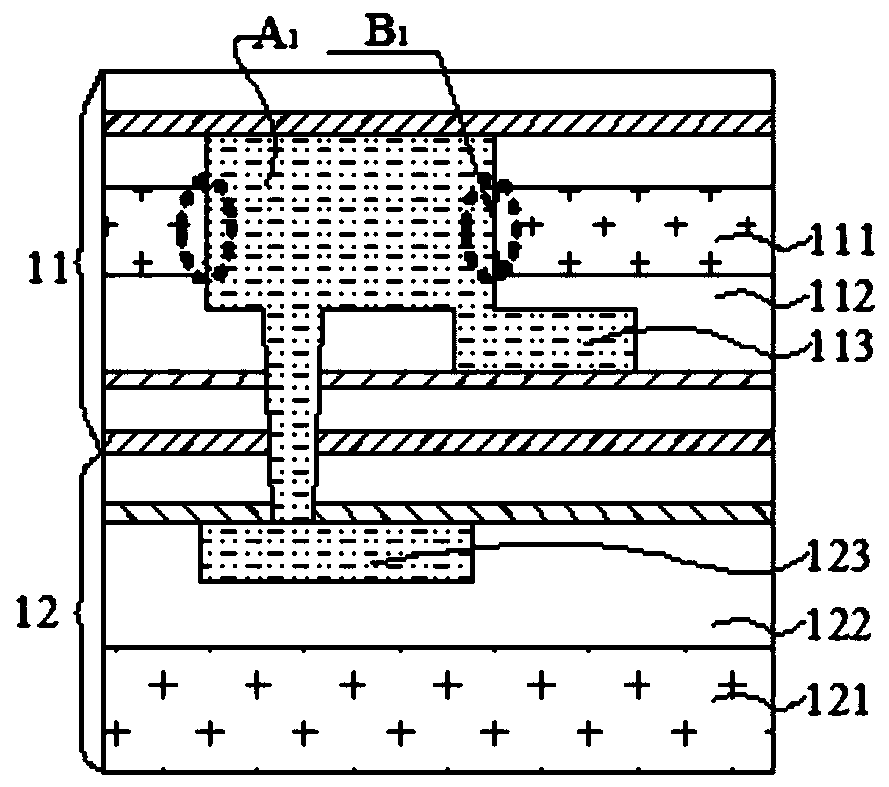

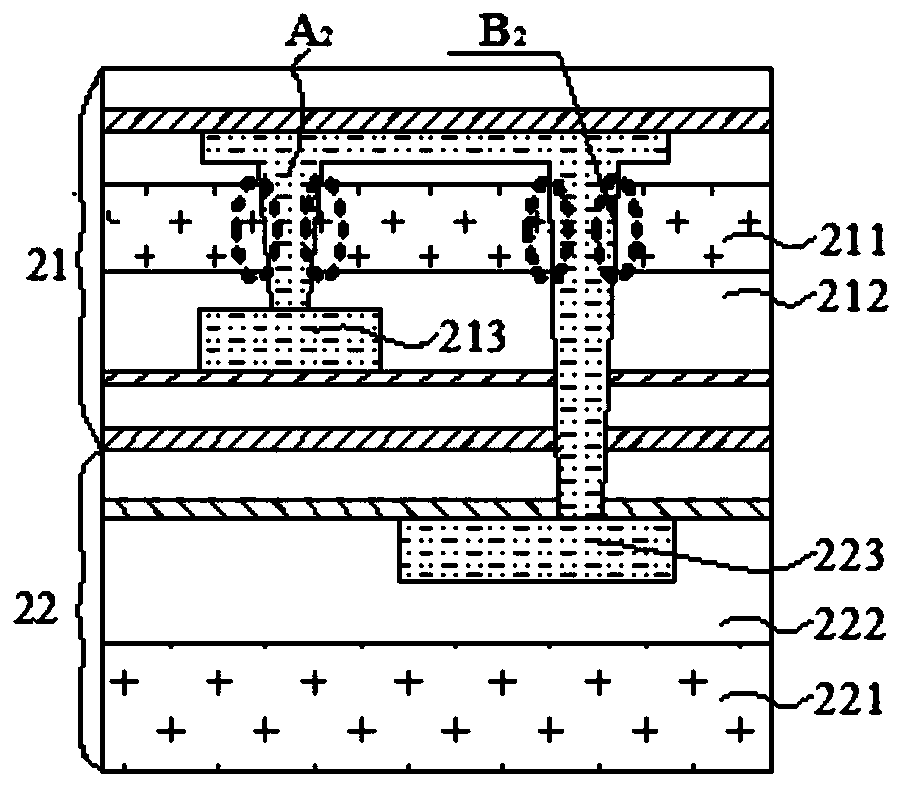

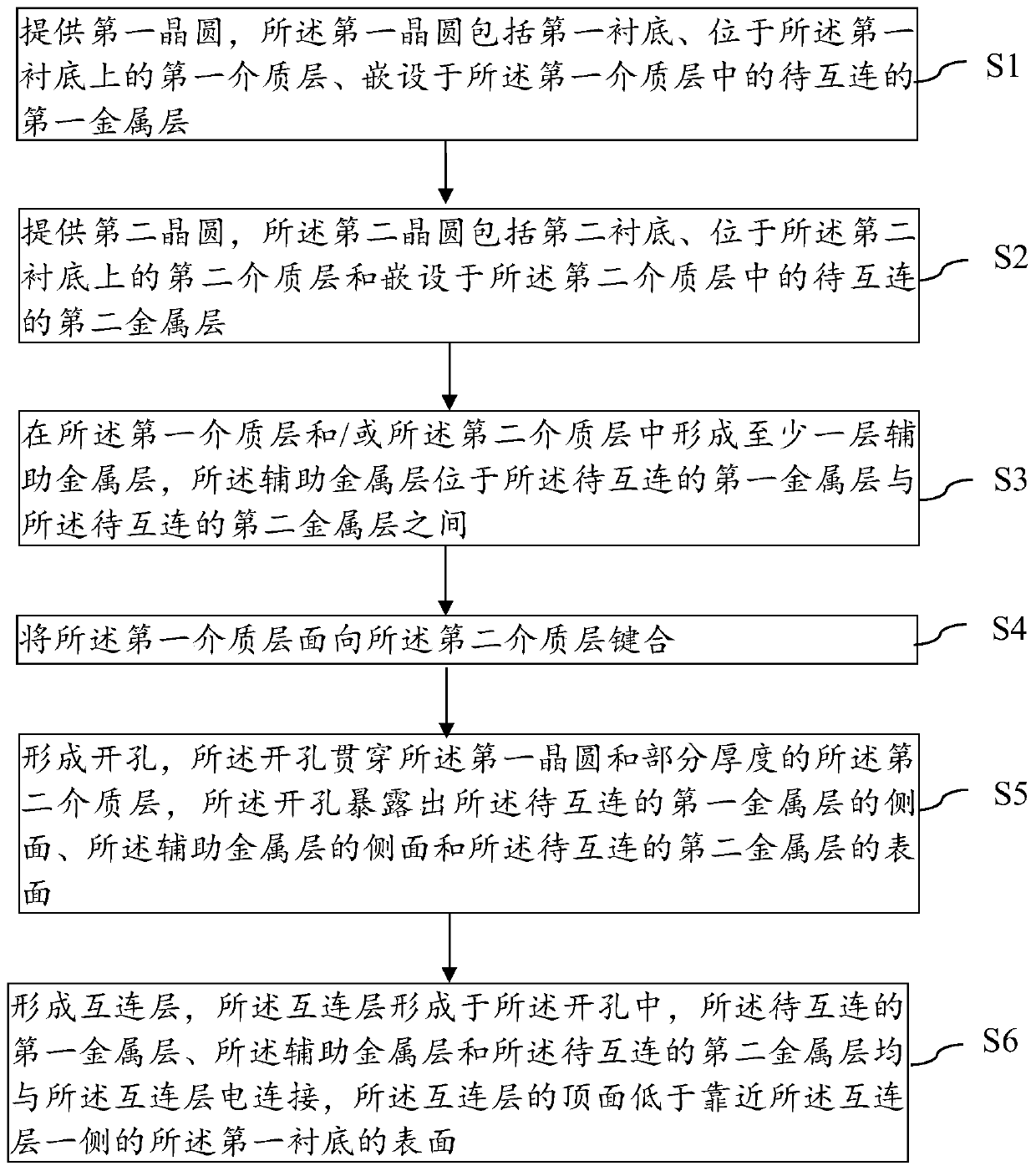

Semiconductor device and manufacturing method thereof

ActiveCN111599793AIncrease the areaGuaranteed insulation performanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceDevice material

The invention provides a semiconductor device and a manufacturing method thereof. The semiconductor device comprises at least one auxiliary metal layer, wherein the auxiliary metal layer is located between a first metal layer to be interconnected and a second metal layer to be interconnected; the side surface of the auxiliary metal layer is exposed by an opening; the area of the exposed metal layer is increased, so that the filling rate of the interconnection layer from the bottom of the opening to the top is increased, the bottom of the opening is filled as soon as possible to form the interconnection layer, and interconnection failure caused by advanced sealing of the top in the interconnection layer filling process is avoided. The top surface of the interconnection layer is lower than the surface of a first substrate close to one side of the interconnection layer; and the interconnection layer is not formed between the penetrating first substrates, so that insulation between the interconnection layer and the first substrates is ensured, the wiring distance between the first metal layer to be interconnected and the second metal layer to be interconnected is reduced, and the wiring capacitance is also reduced at the same time.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

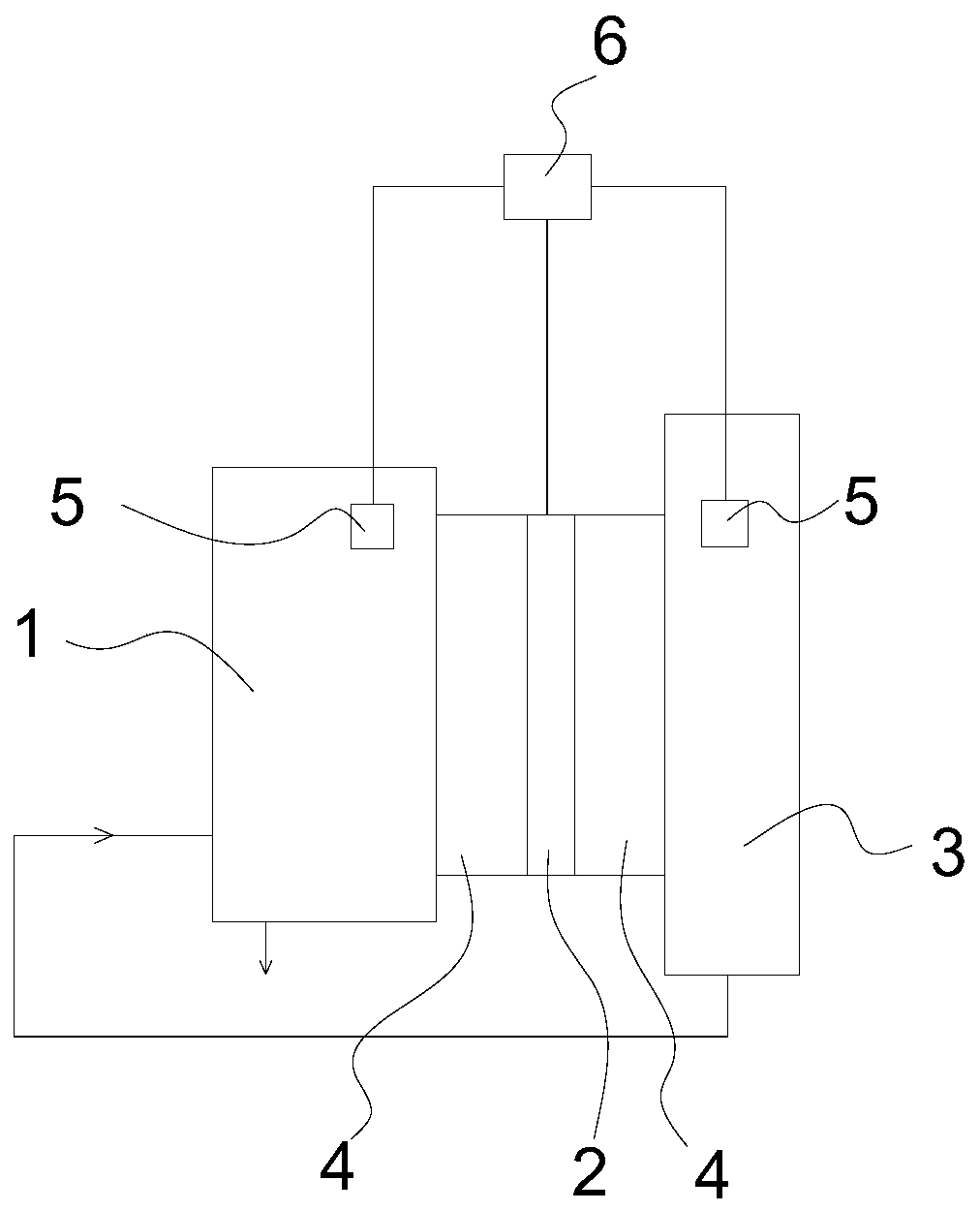

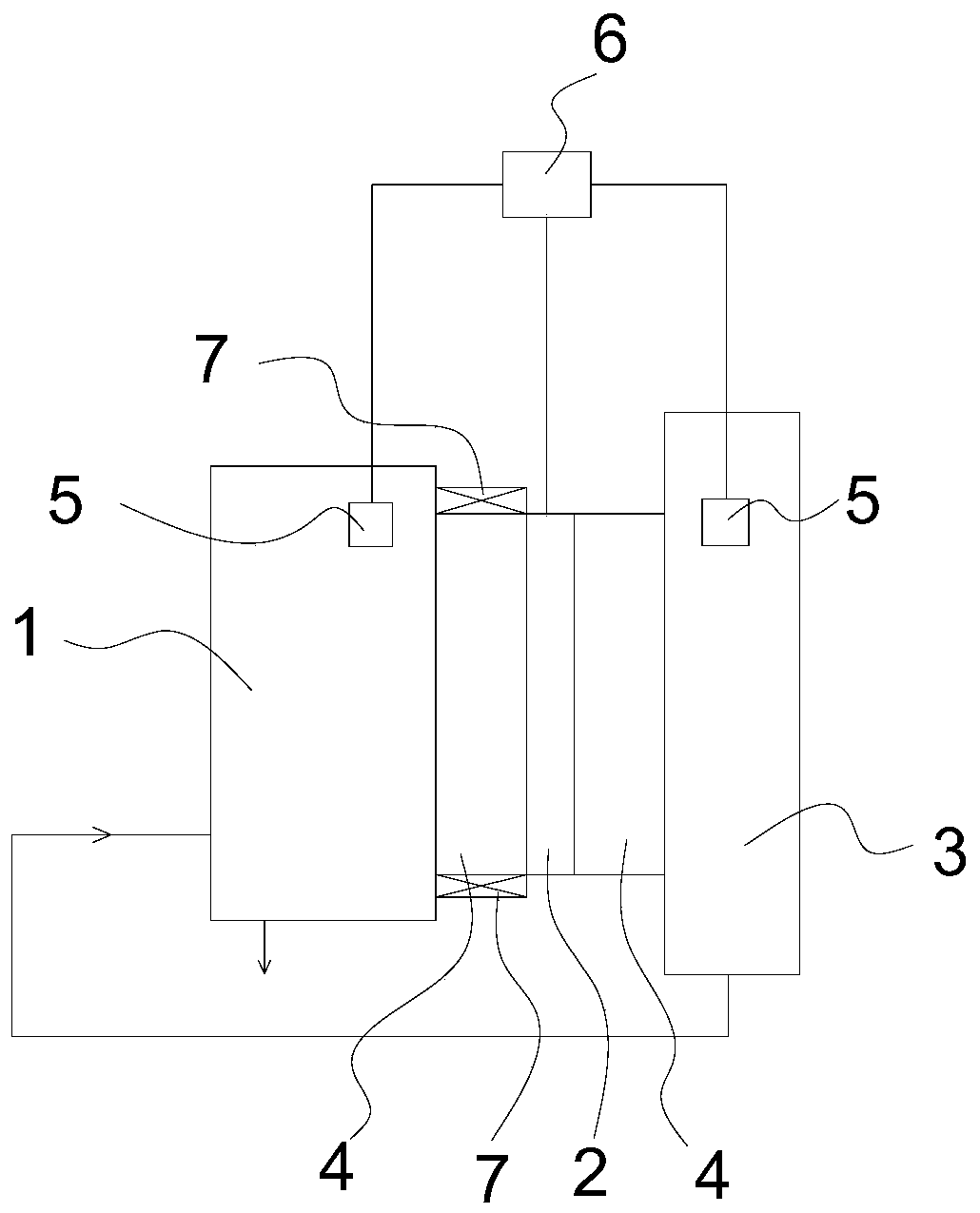

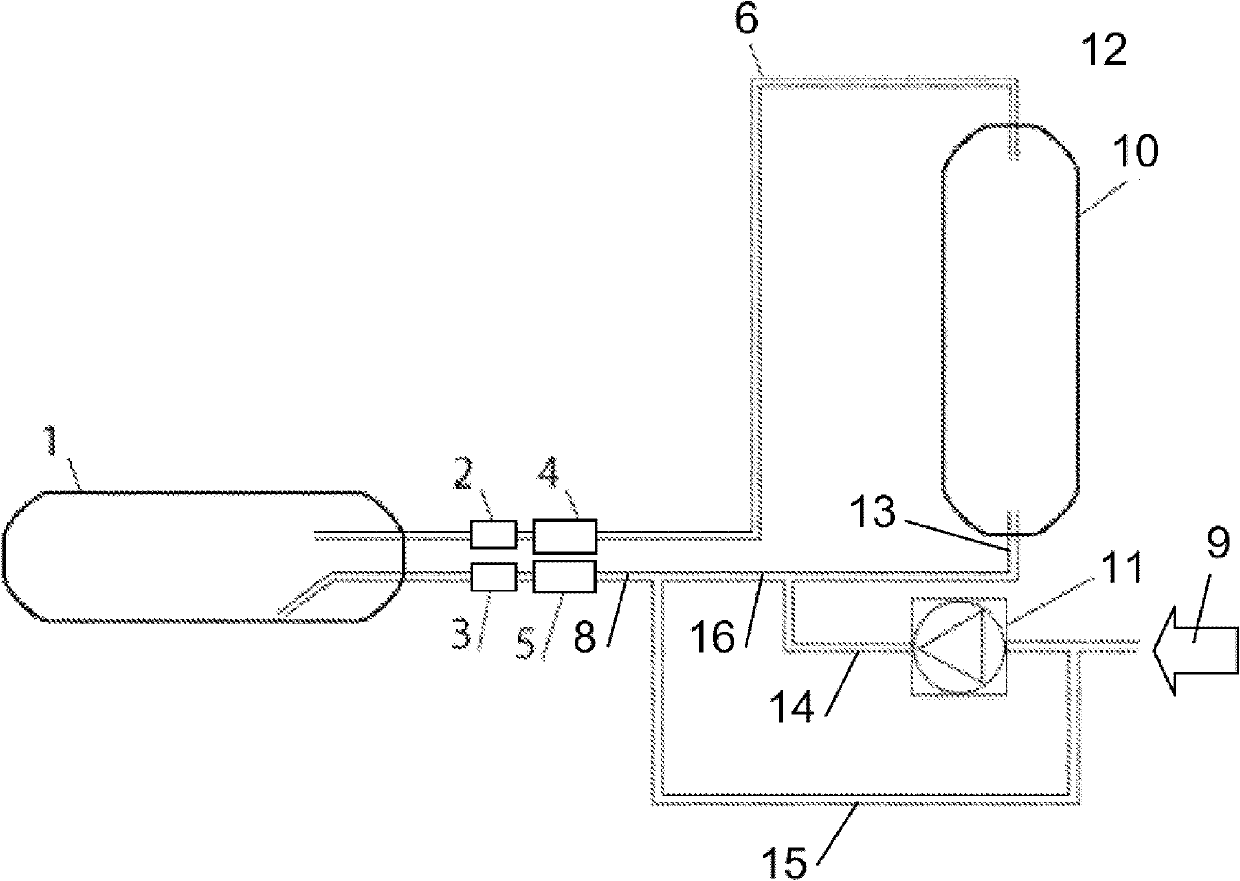

Method and filling installation for filling a hydrogen gas into a vessel

InactiveCN102803817AReduce lossesIncrease filling rateVessel mounting detailsGas handling applicationsHydrogenHydrostatic pressure

The invention discloses a method and a filling installation for filling a hydrogen gas into a vessel (1) having a first port (2) for passing the hydrogen gas and a second port (3) for passing a fluid, wherein the second port (3) is separate from the first port (2). In a first phase a hydraulic fluid is introduced into the vessel (1) through the second port (3) by applying pressure to the hydraulic fluid, such that the hydraulic fluid in the vessel (1) causes a hydrostatic pressure having a pre-determined value. In a second phase the hydrogen gas is introduced into the vessel (1) through the first port (2) by controlling a difference of pressure relative to a current pressure in the vessel (1) for controlling expansion of the hydrogen gas and thereby temperature inside the vessel (1), such that the vessel (1) is filled with the hydrogen gas. To that end the hydraulic fluid is removed from the vessel (1) through the second port (3).

Owner:TEESING

A pvc foam board extrusion die

The invention discloses a PVC foam board extrusion die and relates to the technical field of foam board extrusion dies. The present invention includes a lower template and an upper template matched with the lower template. The upper surface of the lower template is connected with the feeding port in sequence with a diversion buffer zone, a flow equalization zone, and a molding groove; the diversion buffer zone includes a buffer tank; the upper surface of the lower template is located at A pair of L-shaped guide grooves connected with the buffer groove are arranged symmetrically on both sides of the buffer tank; a pair of L-shaped guide grooves are arranged linearly on the opposite side and away from the diversion buffer zone, and a rectangular diversion hole is arranged; the lower surface of the upper template is provided with a feeding The T-shaped diversion groove connected to the mouth; the T-shaped diversion groove communicates with the buffer groove and a pair of L-shaped guide grooves respectively; a pair of L-shaped connecting guide grooves are symmetrically fixed on the lower surface of the upper template. In the present invention, the designed lower template and the upper template are foamed into the molding cavity in three directions, and the PVC foam board is easier to be quickly formed, and the problem of low efficiency of the existing mold in molding the PVC foam board is solved.

Owner:合肥帝品数码科技有限公司

Quantitative filling device and filling method for attitude control power system

ActiveCN109708896BEliminate filling biasDoes not affect filling accuracyGas-turbine engine testingJet-propulsion engine testingIsolation valveSolenoid valve

The invention relates to a quantitative charging device and method of an attitude control power system, and solves the problem of deviation caused by the charging precision of a present charging system. The device comprises a charging console, a vacuum-pumping system, a charging container, an electronic scale, a voltage stabilization system, a charging connector and a charging pipeline; the charging pipeline comprises a conveying pipe, a metal hose, a charging isolating valve, a filter and a charging solenoid valve; one end of the conveying pipe is connected with a tank of the attitude controlpower system via a charging connector, and the other of the conveying pipe is connected with the metal hose; the end, connected with the charging connector, of the charging pipe is provided with a tapping valve; the vacuum-pumping system comprises a vacuum pump, a vacuum pipe and a vacuum gauge; one end of the vacuum pipe is connected with the vacuum pump, and the other end of the vacuum pipe iscommunicated with the charging isolating valve; the voltage stabilizing system comprises an pressurized air bottle, both the charging container and the pressurized air bottle are arranged on the electronic scale, and the pressurized air bottle is communicated with the charging container; and the charging container is communicated with the conveying pipe of the charging pipe via the tapping valve of the charging container.

Owner:XIAN AEROSPACE PROPULSION TESTING TECHN INST

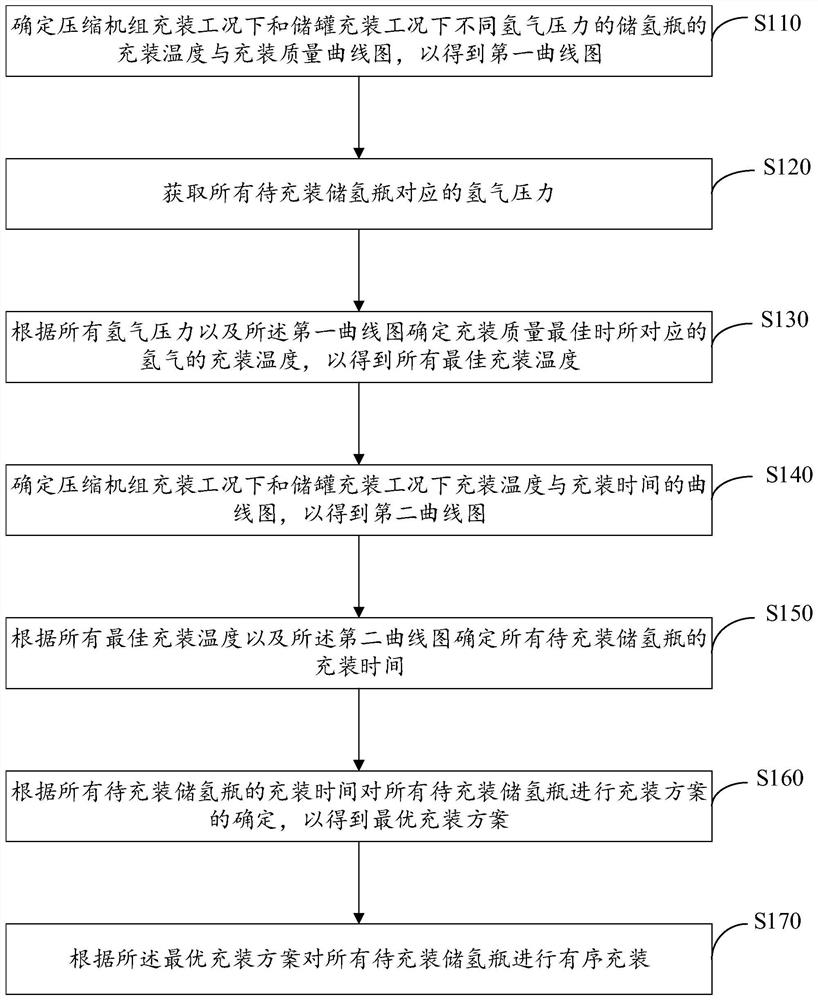

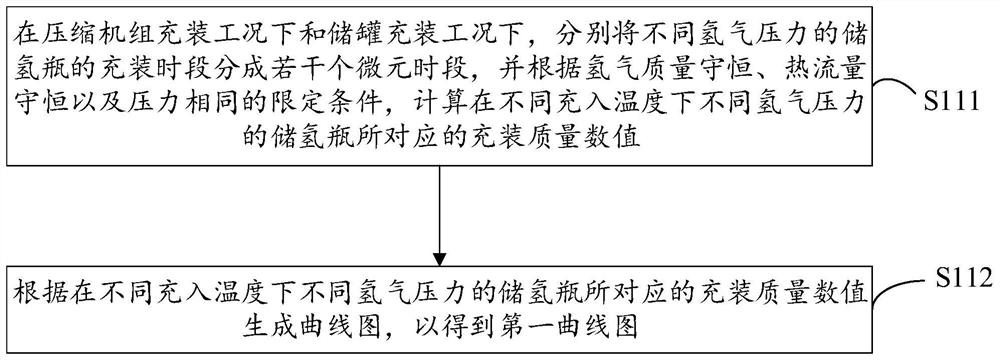

Hydrogen refueling station hydrogen energy filling control method and device, computer equipment and storage medium

ActiveCN114462863AIncrease filling rateGood filling performanceResourcesHydrogen pressureEngineering

The embodiment of the invention discloses a hydrogen refueling station hydrogen energy filling control method and device, computer equipment and a storage medium. The method comprises the following steps: determining a charging temperature and charging quality curve graph of hydrogen storage cylinders with different hydrogen pressures under a compressor unit charging working condition and a storage tank charging working condition; hydrogen pressure corresponding to all the hydrogen storage cylinders to be filled is obtained; the corresponding hydrogen filling temperature when the filling quality is optimal is determined, so that all the optimal filling temperatures are obtained; a curve graph of the filling temperature and the filling time under the compressor unit filling working condition and the storage tank filling working condition is determined; the filling time of all the hydrogen storage bottles to be filled is determined; the filling scheme of all the hydrogen storage bottles to be filled is determined, so that the optimal filling scheme is obtained; and all the hydrogen storage bottles to be filled are filled in order. By implementing the method provided by the embodiment of the invention, the filling temperature can be adjusted in real time according to the automobile hydrogen storage bottles with different pressures, so that the filling speed is increased, and the filling effect when a plurality of automobile hydrogen storage bottles are filled in line is improved.

Owner:内蒙古中科装备有限公司 +1

Magnetron sputtering chambers and semiconductor processing equipment for TSV filling

ActiveCN107068599BIncrease filling rateIncrease ionization rateVacuum evaporation coatingSputtering coatingPhysical chemistrySemiconductor

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A horizontal construction method of underwater mold bag concrete

ActiveCN111206548BDoes not affect the normal release of waterEasy to set upBarrages/weirsFoundation engineeringUnderwaterArchitectural engineering

The invention discloses a horizontal construction method of underwater mold bag concrete, which relates to the field of water conservancy engineering and includes the following steps: S1, construction preparation; S2, repairing the reinforcement surface; S3, laying and fixing the mold bag; S4, preparing concrete; S5, Concrete filling of mold bag; S6, underwater inspection. The invention has the following advantages and effects: the above-mentioned construction method is simple and can be directly repaired at the damaged position, and compared with the scheme of building cofferdams on the river course, the construction period can be greatly shortened. At the same time, a large amount of earthwork excavation is reduced, which not only saves investment, but also protects the environment. And during the construction process, it will not affect the normal release of water from the sluice, and there will be no pollution to water resources.

Owner:福建省水利水电工程局有限公司

Copper Plating Method

The invention discloses a method for electroplating copper. In the method, stage-type electroplating technique is adopted for treatment, namely, the electroplating technique for treatment is carried out in different stages under the conditions of different current densities, rotating speeds of a silicon wafer, flow rates of electroplate liquid and technical positions of the silicon wafer, so that high filling speed can be guaranteed, the step height with a large size and depth figure is effectively reduced compared with an area without the figure, the thickness of a copper film needed by the electroplating technique can be indirectly reduced on the premise of guaranteeing a chemically mechanical polishing process window, the electroplating technique time and the chemically mechanical polishing process time are further reduced, and the chemical materials are saved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

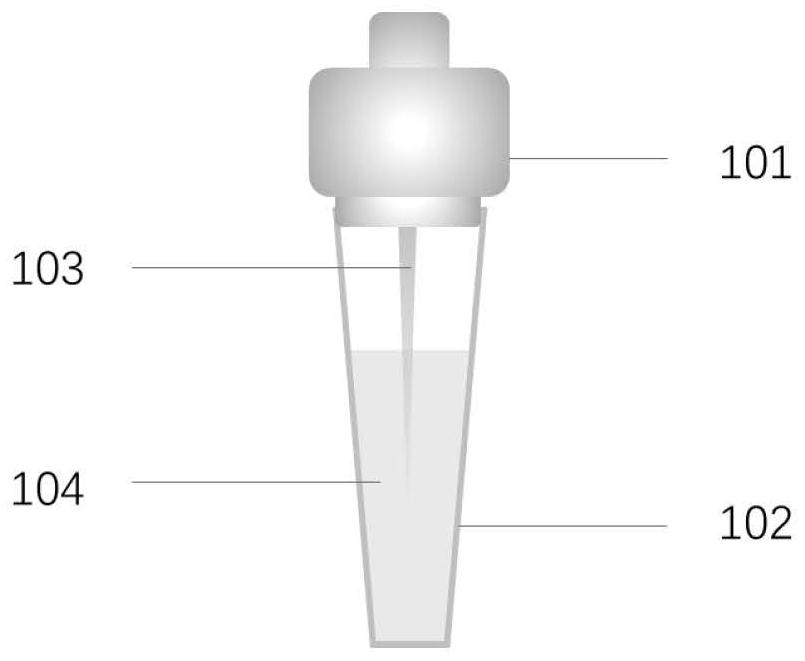

Glass needle tip nanopore filling device based on vacuum method and using method thereof

ActiveCN112146956AMuch lossNature will not changePreparing sample for investigationEngineeringMechanical engineering

The invention belongs to the technical field of life science and biomolecule detection, and relates to a needle tip nanopore filling device. The device comprises a centrifuge pipe and a clamp holder clamped on the centrifuge pipe in a sealed mode, wherein a liquid containing tank is integrally formed at the top of the clamp holder; and the clamp holder is in a up-down through mode, and a glass pipe with a needle tip nanopore structure is arranged in a through hole in the middle part of the clamp holder in an inserted mode. The problems that a whole glass needle tip nanopore is difficult to fill and needle tip bubbles are difficult to discharge in a glass needle tip nanopore filling method for injecting filling liquid into a micropipe by adopting a microinjector in the prior art are solved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Energy-saving and environment-friendly rapid circulation filling head for viscous cosmetics

ActiveCN112407366AFast fillImprove filling efficiencyLiquid materialEngineeringMechanical engineering

The invention relates to the technical field of cosmetic production equipment, and discloses an energy-saving and environment-friendly rapid circulation filling head for viscous cosmetics. The fillinghead comprises a filling hopper, the bottom of the filling hopper is fixedly connected with a liquid outlet pipe, the inner side wall of the filling hopper is movably connected with an inner rotatingplate, and the outer side wall of the inner rotating plate is fixedly connected with an outer fluted disc; and the outer side wall of the outer fluted disc is engaged with driving teeth. A channel isformed from an outlet in the liquid outlet pipe of the inner rotating plate to the highest surface of a cosmetic solution, so that external air at the outlet of the inner rotating plate can enter thechannel, the resistance of the air to the solution can be reduced to the minimum, the solution can quickly enter a filling opening through the liquid outlet pipe, and therefore the filling efficiencyof the cosmetic solution with the larger viscidity can be improved. Meanwhile, the filling head can quickly fill the cosmetic solution with the larger viscosity without pressurizing the solution by virtue of extra pressurizing equipment, so that the consumption of electric energy is effectively reduced, and the aims of energy conservation and environmental protection are achieved.

Owner:聊城市瀚格智能科技有限公司

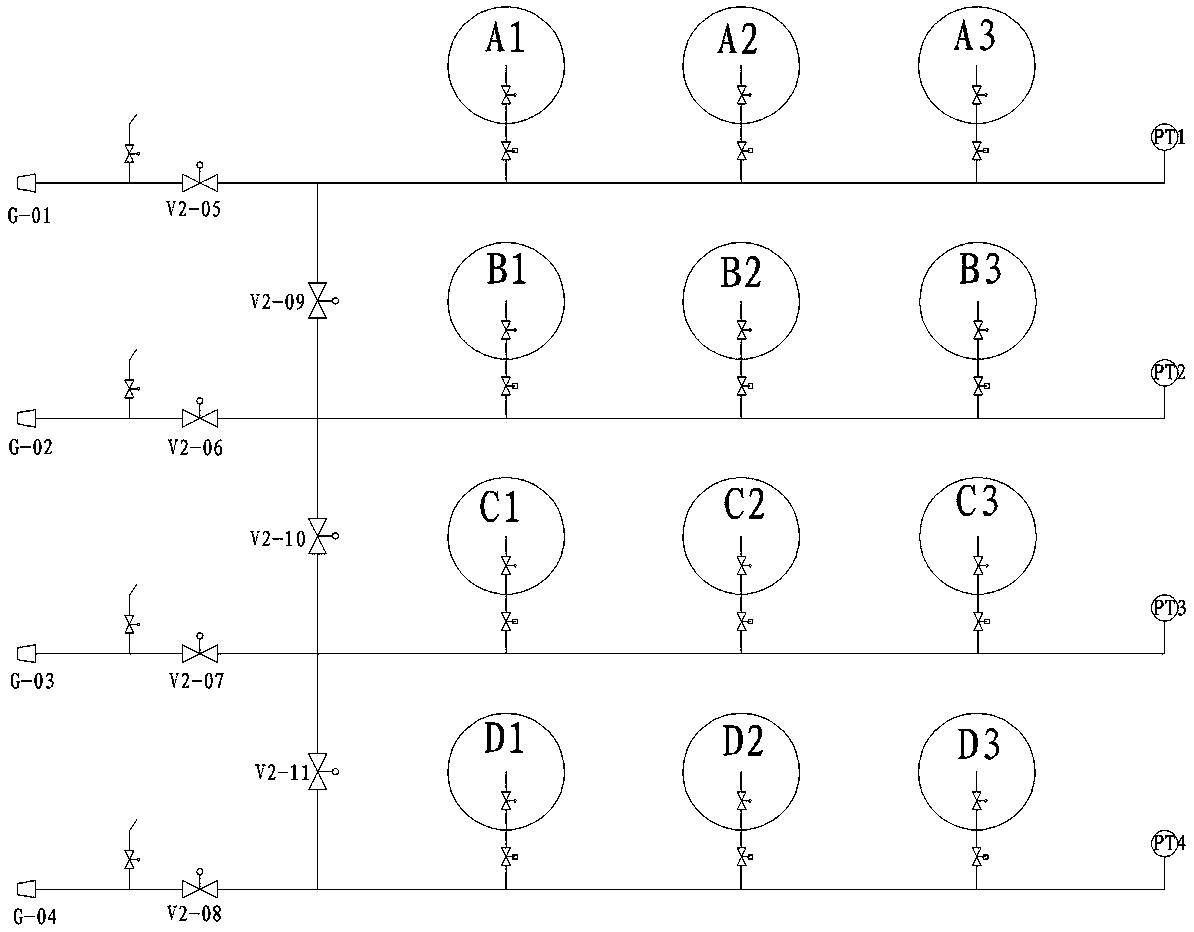

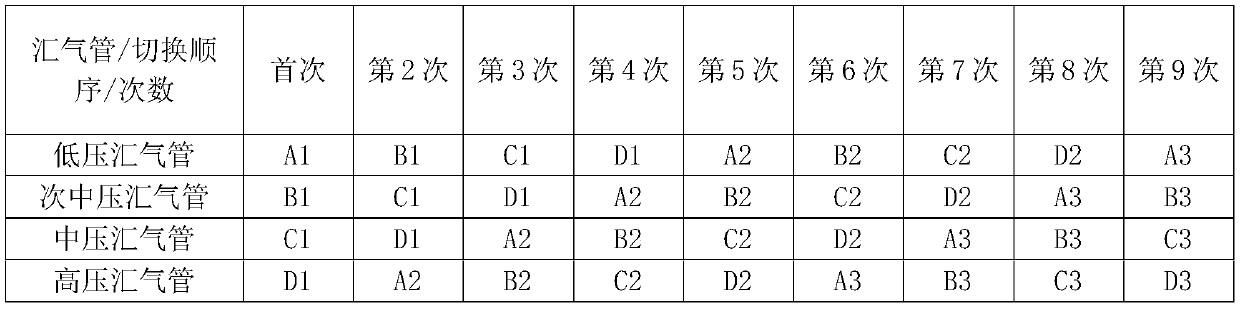

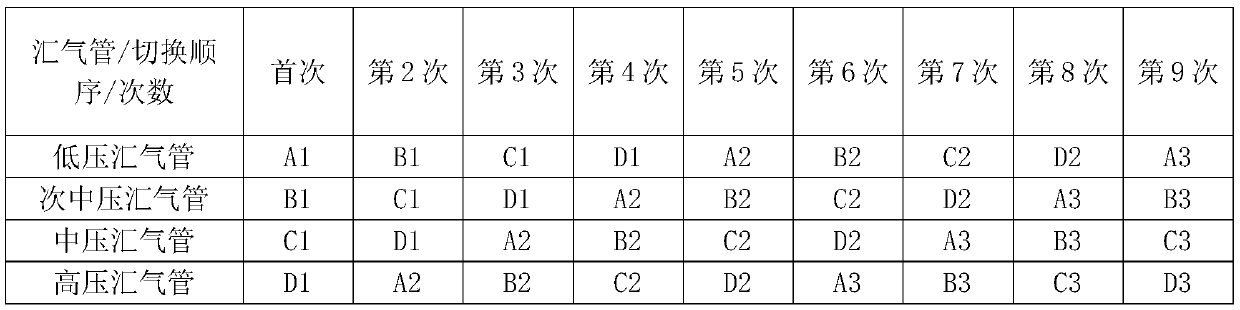

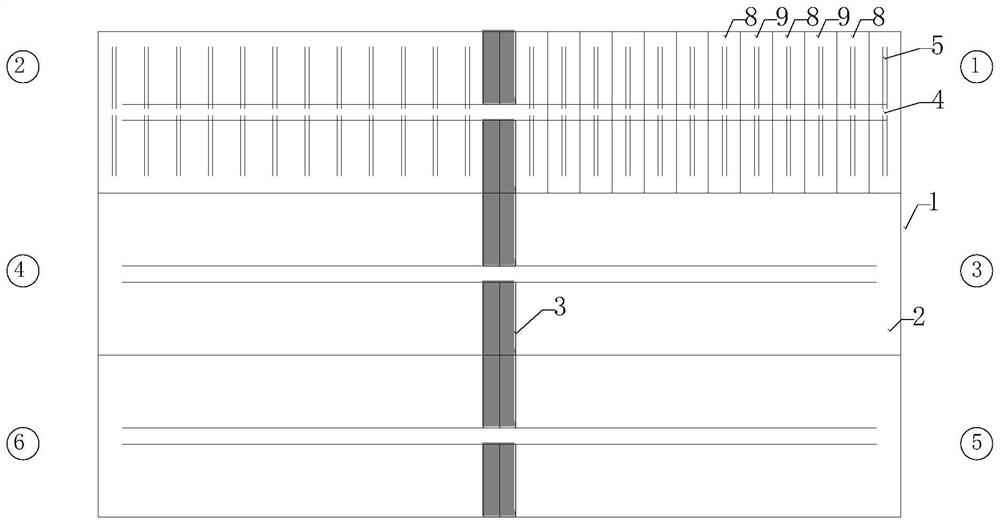

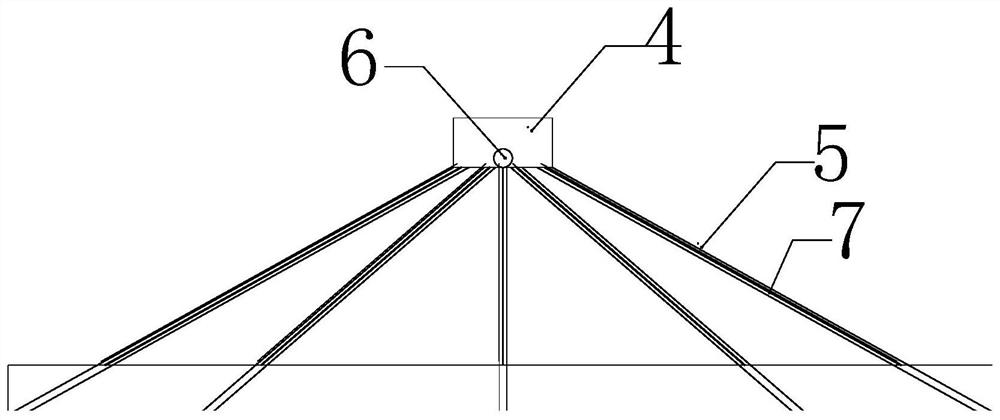

Unpowered natural gas filling station with cycle alternate control system and control method

ActiveCN107620866BIncrease the number of combinationsReduce the number of combinationsPipeline systemsGas cylinderControl system

The invention provides an unpowered natural gas filling station provided with a cyclic and alternate control system and a control method. Based on a cylinder twining pipe bundle type container trailerassembly provided with an interconnected controllable valve pipeline system, opening-closing regulation and control of valves of independent gas cylinders connected to all gas collection pipes and switching connection between the independent gas cylinders and the gas collection pipes are achieved by detecting the pressure states of all the gas collection pipes, switching of pipelines and gas cylinders between trailers are achieved, and an independent gas cylinder cyclic and alternate switching sequence table and a special memory for pressure switching values are stored in a valve management and control module of the trailer assembly. According to the unpowered natural gas filling station provided with the cyclic and alternate control system and the control method, the time for parking twotrailers at the same time is shortened, and the trailers can have more time to travel to a primary filling station for gas filling.

Owner:SHIJIAZHUANG ENRIC GAS EQUIP

Foundation reinforcing method for building construction

InactiveCN114753882AImprove recovery rateReduce distractionsMining devicesMaterial fill-upResource recoveryArchitectural engineering

A foundation reinforcing method for building construction comprises the steps that natural resources under a building area are divided into a plurality of rectangular mining areas, and the interior of each mining area is divided into a rectangular working face in the trend; a top drainage roadway is constructed above each working face along the trend, and layer-crossing drilling holes are respectively constructed to the ore bed of each working face from the top drainage roadway; working face stoping is carried out after gas extraction, in the stoping process, an extraction steel pipe is lengthened from the upper end, filling and supporting are carried out, and a filling strip is formed; filling the strip mined-out areas between the filling strips of the working face, and repeating the steps until the whole mining area is mined; in the construction process, building construction is normally conducted on the ground, resource recovery and ground construction are synchronously conducted and do not interfere with each other, and the foundation is stable after resource recovery.

Owner:刘朝军

A kind of preparation method of superhydrophobic reentrant t-shaped microcolumn structure

InactiveCN104649216BAvoid multiple sputteringAvoid filling multiple timesDecorative surface effectsCoupling light guidesProcess windowProtection layer

The invention discloses a preparing method of a superhydrophobic concave angle T-shaped microcolumn structure. The method comprises the steps of (a), rotationally coating photoresist on one surface of a chip and executing developing operation to obtain a first round hole array; (b), depositing an adhesion layer and a seed layer on the surface of the photoresist in sequence; (c) rotationally coating the photoresist on the surface of the seed layer and executing the developing operation to obtain a second round hole array; (d), performing plating and filling on the first round hole array and the second round hole array to obtain a metal T-shaped microcolumn structure; (e) removing the photoresist and surplus adhesion layer and seed layer; (f), depositing a protection layer on the surface of the T-shaped microcolumn; (g), removing a lateral extending part of the microcolumn T-shaped structure and remaining a columnar structure and the protection layer to obtain one concave angle T-shaped microcolumn structure. According to the method, a target structure of different sizes can be prepared controllably, a process window is wide, the repeatability is good, the chemical stability is high, and the superhydrophobic concave angle T-shaped microcolumn structure has excellent superhydrophobic performance and self-cleaning capacity.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com