Copper Plating Method

A technology of electroplating copper and electroplating solution, which is applied to circuits, semiconductor devices, etc., can solve the problems of increasing the burden of electroplating process and chemical mechanical polishing process, slow deposition rate of electroplating copper, and lack of control of graphics, so as to shorten the electroplating process time and chemical Mechanical polishing process time, reduction of copper film thickness, effect of high fill rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

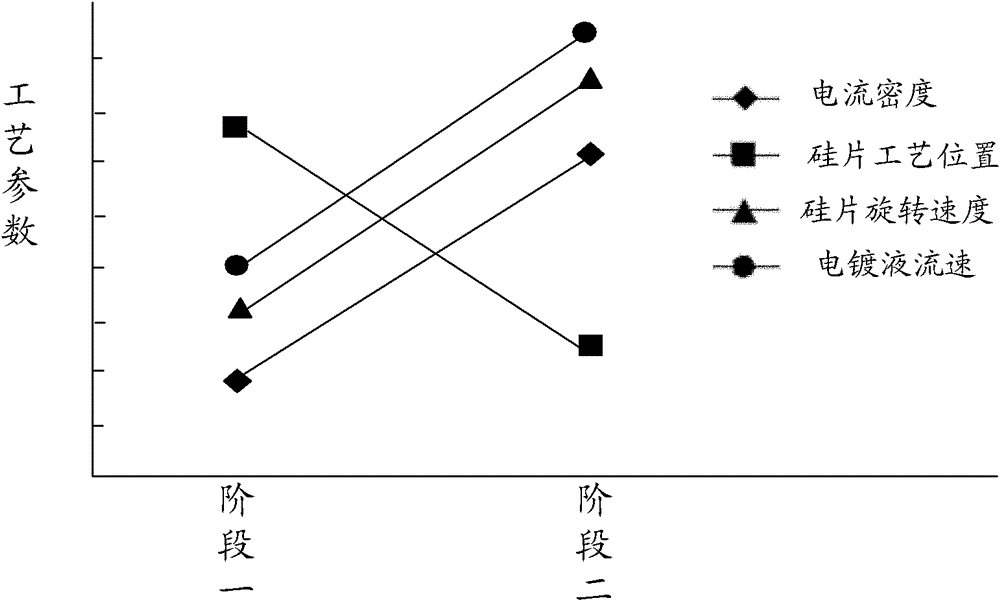

[0030] Please refer to figure 1 , figure 1 The schematic diagram of the process parameter of each treatment stage of the electroplating copper method that the first embodiment of the present invention provides, in conjunction with figure 1 , the electroplating copper method provided by the embodiment of the present invention is used to form a copper coating film on a large-scale, large-depth integrated circuit pattern. The method adopts a step-by-step electroplating process. And the electroplating process is carried out in stages under the condition of the silicon wafer process position. Therefore, while ensuring a high filling rate, the step height of the large-size, large-depth pattern relative to the non-patterned area is effectively reduced, and the electroplating process is indirectly reduced on the premise of ensuring the chemical mechanical polishing process window. The thickness of the copper film is reduced, thereby shortening the electroplating process time and the...

Embodiment 2

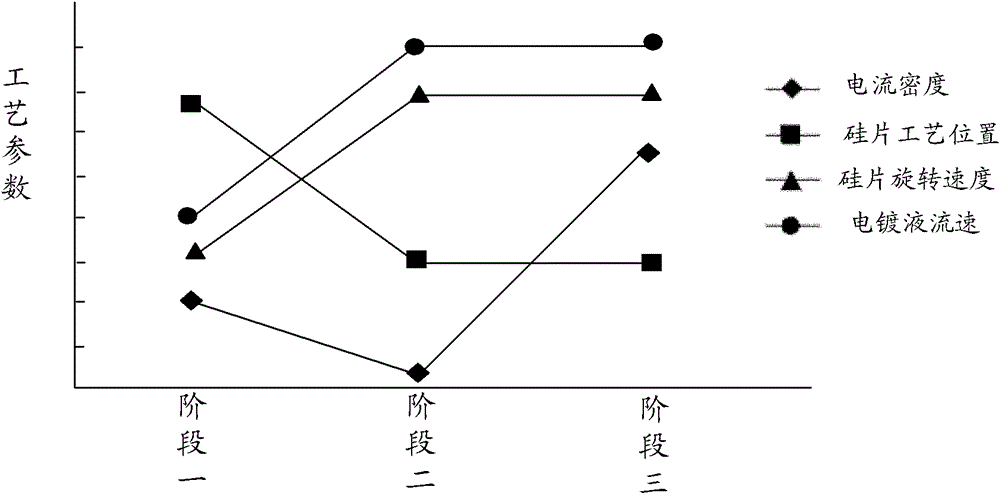

[0042] Please refer to figure 2 , figure 2 A schematic diagram of the process parameters of each treatment stage of the copper electroplating method provided by the second embodiment of the present invention, combined with figure 2 , different from the above-mentioned first embodiment, the staged electroplating process provided by the second embodiment of the present invention also includes a transition stage, the transition stage is located between the initial stage and the final stage, so The current density of the transition stage is lower than the current density of the initial stage, the position of the silicon wafer, the rotation speed of the silicon wafer and the flow rate of the electroplating solution in the transition stage are different from the position of the silicon wafer, the rotation speed of the silicon wafer and the flow rate of the electroplating solution in the final stage. The flow rate is the same.

[0043] The above three stages are described in det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com