Unpowered natural gas filling station with cycle alternate control system and control method

A control method and gas filling station technology, applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of low filling efficiency, slow speed, and increased number of combinations, so as to improve filling efficiency, The effect of increasing the gas filling speed and increasing the number of combinations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

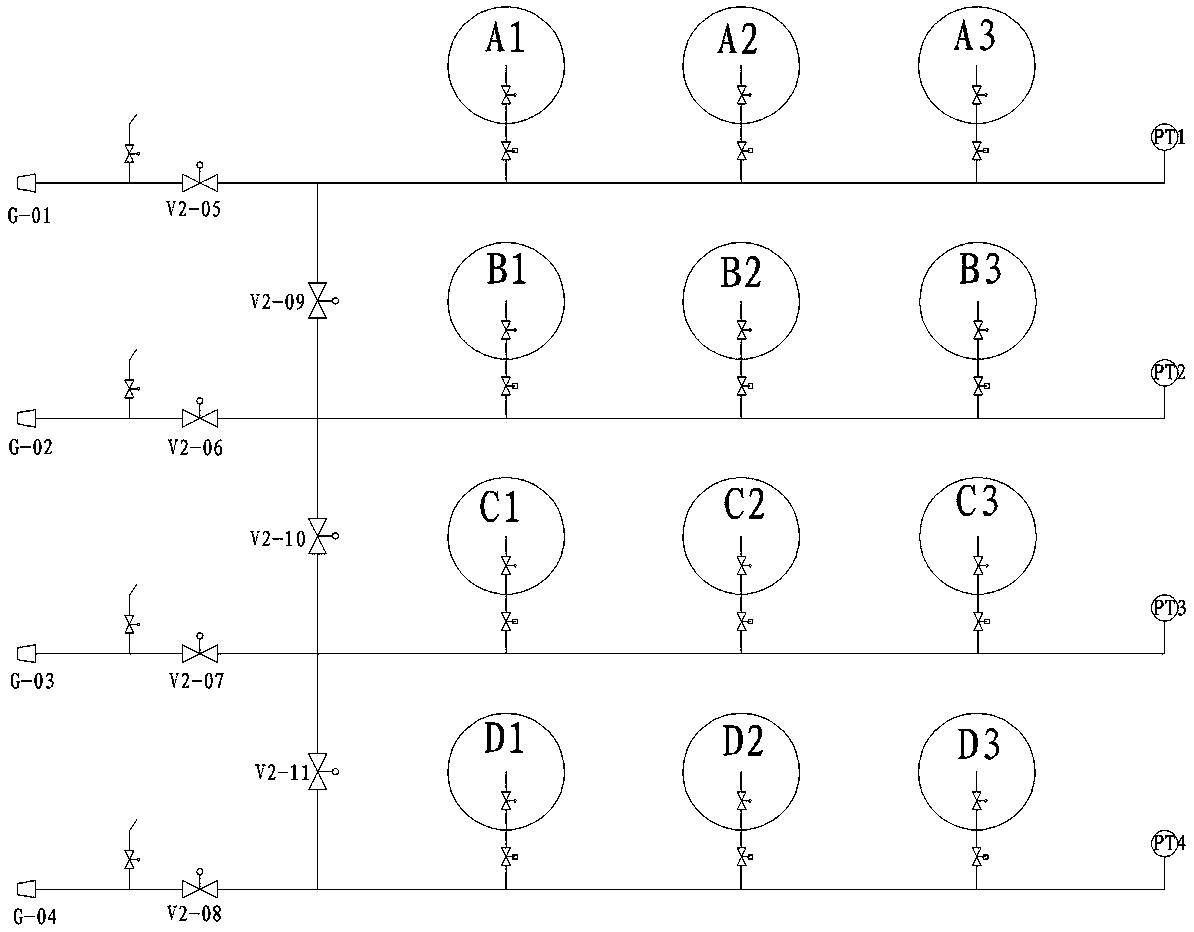

[0052] figure 1 It is a diagram of the intercommunicating controllable valve pipeline system in the present invention, and the system includes:

[0053] 1) Low, sub-medium, medium and high pressure manifolds G-01~G-04;

[0054] 2) The cut-off valves V2-05~V2-08 and pressure gauges PT1~PT4 are respectively arranged on each gas manifold;

[0055] 3) Four groups of gas cylinder groups A, B, C and D respectively connected to their respective gas manifolds. The gas cylinders directly connected to each manifold are respectively defined according to the order of the manifolds: low-pressure pipes connected to gas cylinders A1~A3, sub-medium pressure pipes connected to gas cylinders B1~B3, medium-pressure pipes connected to gas cylinders C1-C3, high-pressure pipes connected to gas cylinders Cylinder D1~D3;

[0056] 4) Bypass valves V2-09~V2-011 respectively arranged between adjacent gas manifolds.

[0057] The above four sets of pressure gauges PT1-PT4 are all connected to the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com