Stainless steel wire mesh circulating water vapor membrane filter-bag type fine dust removal device for coal-fired flue gas

A technology for coal-fired flue gas and dust removal equipment, which is applied in the fields of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of high investment and operating costs, unstable combustion of boilers, and increased operating resistance, etc. Low investment and operating costs, low resistance, and the effect of reducing flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

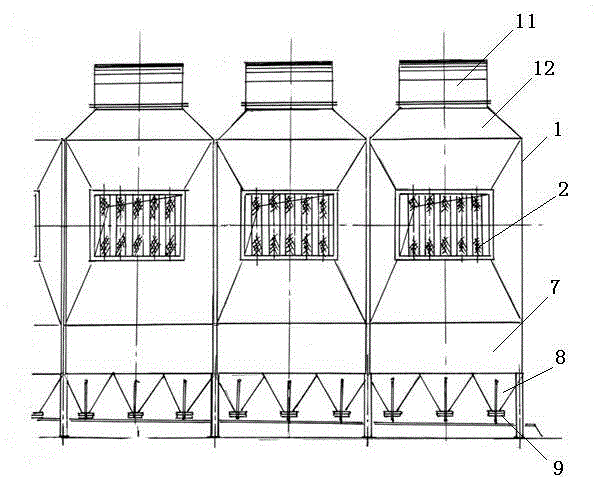

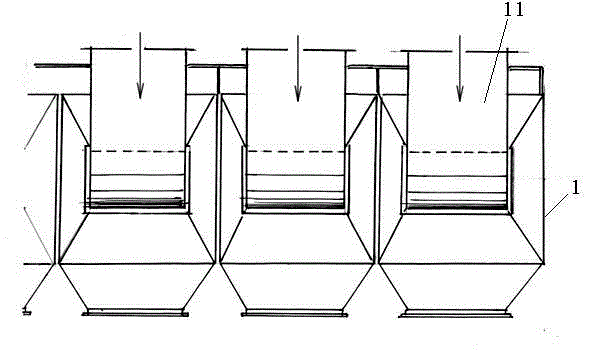

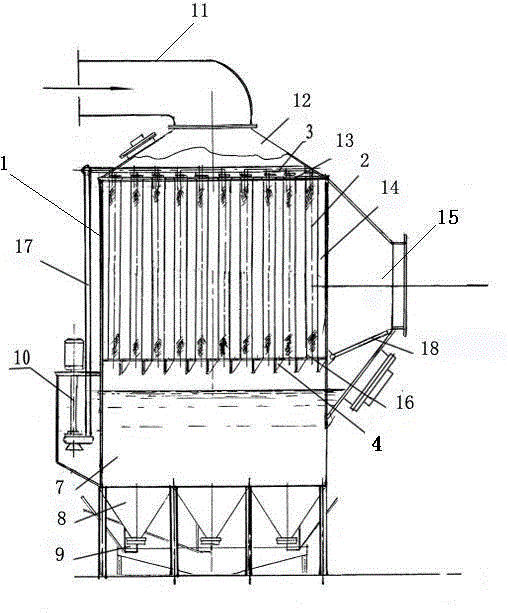

[0029] see figure 1 -8, the names of parts are as follows: bag chamber 1, stainless steel wire mesh cloth filter bag 2, water spray ring 3, discharge door 4, vertical cone flange mouth 5, rubber pressure plate 6, sedimentation tank 7, and more sedimentation tanks Cone bucket 8, push handle type rubber plug valve 9, submerged circulating water pump 10, smoke inlet duct 11, smoke hood 12, filter bag upper orifice plate 13, filter bag outer clean air chamber 14, smoke discharge port 15, filter bag Orifice plate 16 under the bag, clean water upper water pipe 17, switchable windshield 18, fixed pressure ring 19, lower smoke inlet air duct 20, upper smoke discharge port 21, clean air chamber 22 outside the bag, lower orifice plate 23.

[0030] see Figure 5 , Image 6 , Figure 7 , Coal-fired flue gas stainless steel wire mesh cloth circulating water vapor membrane filter bag type fine dust removal equipment includes bag room 1 (body), which can increase the combination of monome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com