Automatic bottled chili sauce filling device

A technology of automatic filling and chili sauce, applied in bottle filling, packaging, liquid bottling, etc., can solve the problems of long time, unfavorable enterprise production and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

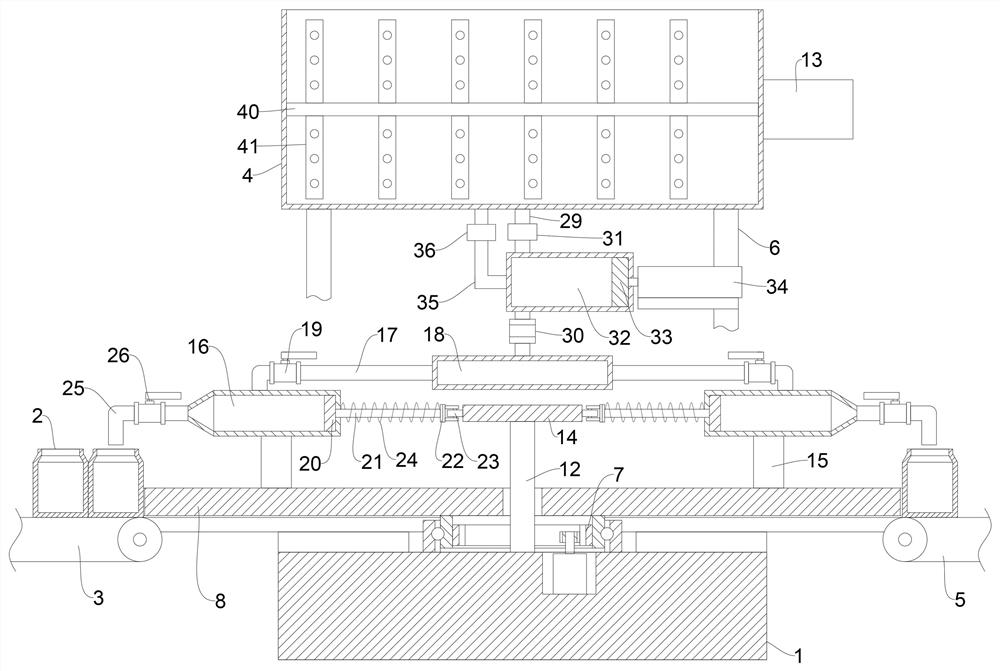

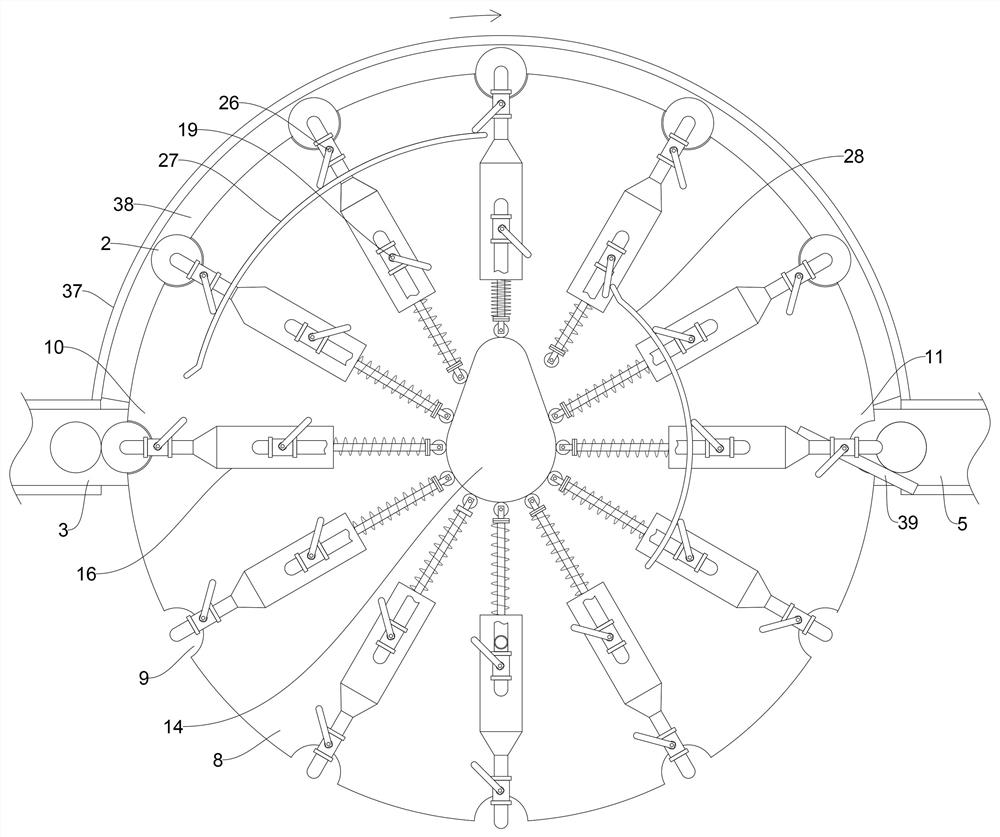

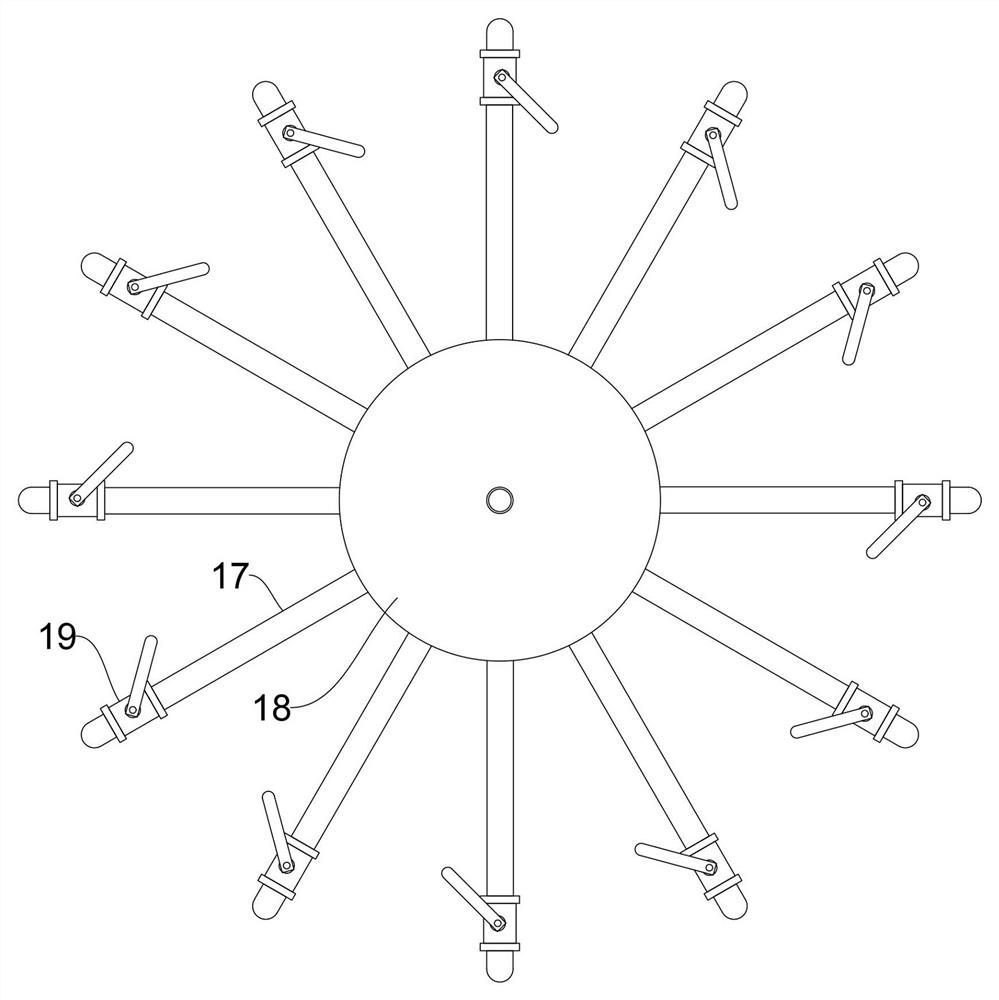

[0020] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 Shown: a kind of bottled chili sauce automatic filling device, comprises filling table 1, the bottle body 2 that is used to dress chili sauce, is used to convey the empty bottle conveyer belt 3 of unloaded bottle body 2 to feeding station 10, uses It is used to store the sauce tank 4 to be filled with chili sauce and the sauce bottle conveyor belt 5 for outputting the fully loaded chili sauce bottle body 2. The sauce tank 4 is fixed on both sides of the filling platform 1 through the frame 6, and the filling A hollow electric turntable 7 is installed on the platform 1, and a filling turntable 8 is installed on the hollow electric turntable 7. The frame 6 spans the filling turntable 8 and does not contact the filling turntable 8, and does not interfere with the rotation of the filling turntable 8. There is a semicircular notch 9 on the edge of the loading turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com