Device for controlling hydrogen release efficiency of alloy hydrogen storage equipment

A release efficiency and hydrogen storage technology, applied in electrical components, fuel cell heat exchange, fuel cell additives, etc., can solve the problems of low hydrogen absorption and desorption rate, and achieve the effect of increasing the filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

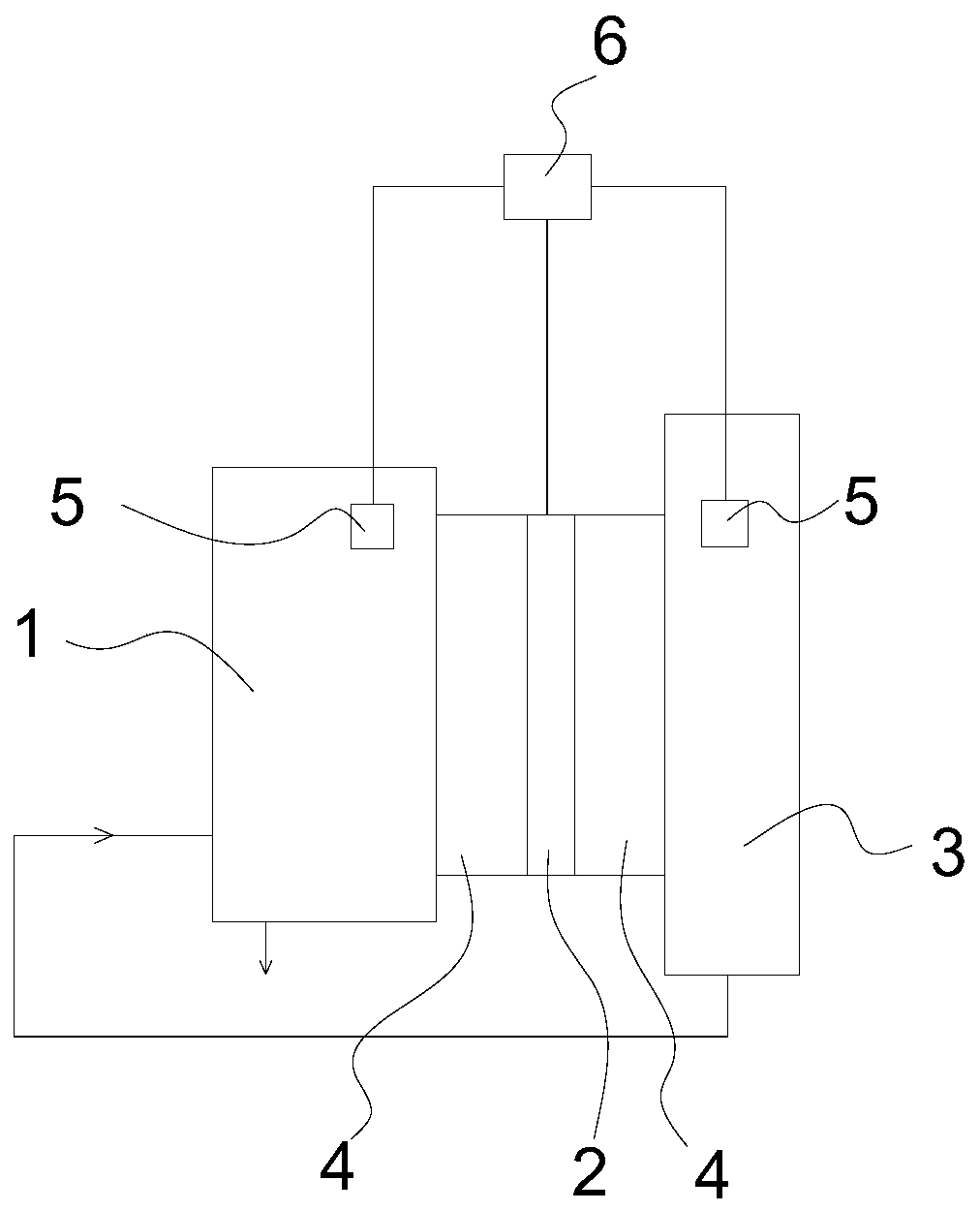

[0028] Such as figure 1 As shown, a device for controlling the hydrogen release efficiency of an alloy hydrogen storage device includes a fuel cell 1, a semiconductor refrigeration chip 2, an alloy hydrogen storage device 3, a heat transfer medium 4, two temperature sensors 5, and a controller 6; The hydrogen device 3 is connected to the fuel cell 1 through pipelines, and the alloy hydrogen storage device 3 provides hydrogen for the fuel cell. The bottom of the fuel cell 1 is provided with a water outlet. 1 is connected to the alloy hydrogen storage device 3, and the heat conduction medium 4 is mainly installed on the outer surface of the fuel cell 1 and the alloy hydrogen storage device 3, and the heat conduction medium 4 is in close contact with the semiconductor refrigeration sheet 4 and is coated with heat conduction silicone grease, wherein One temperature sensor 5 is set on the fuel cell 1 and connected to the controller 6 , and the other temperature sensor 5 is set on t...

Embodiment 2

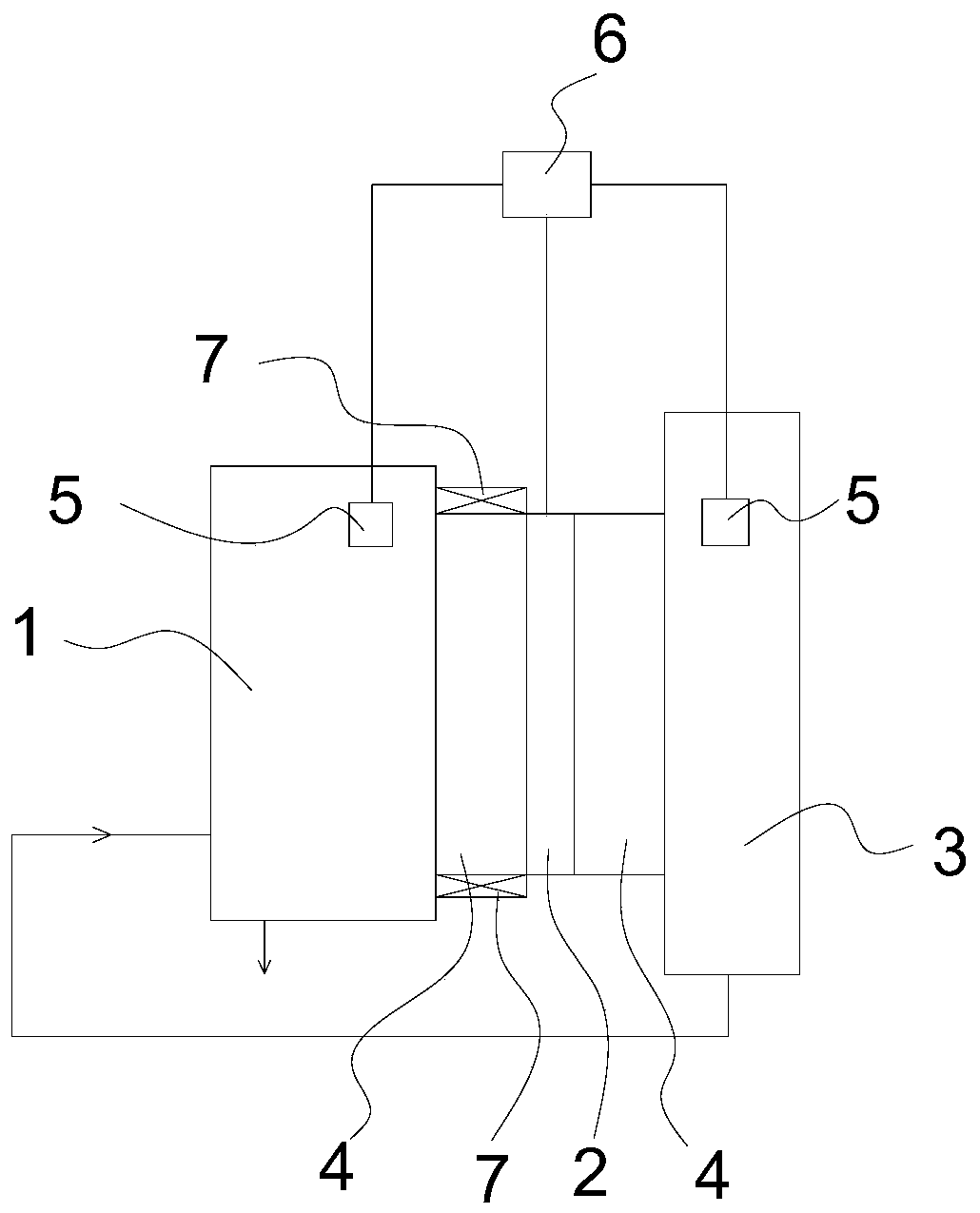

[0038] Such as figure 2 As shown, on the basis of the first embodiment, heat sinks 7 are added at the upper and lower ends of the heat transfer medium installed on the surface of the fuel cell 1 .

[0039] The cooling device 7 is an air cooling device or a water cooling device.

[0040] In this embodiment, the heat dissipation device 7 is a heat dissipation fan.

[0041] When the alloy hydrogen storage device 3 is filled with hydrogen, the semiconductor refrigerating sheet 2 changes the direction of the energized current to exchange the hot and cold ends, and the cold end cools down the alloy hydrogen storage device 1 that generates heat due to the filling of hydrogen through the heat conduction medium 4, so as to Increase the hydrogen filling rate, and turn on the cooling fan at the hot end to reduce its temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com