Glass needle tip nanopore filling device based on vacuum method and using method thereof

A nanopore and vacuum technology, applied in the fields of life science and biomolecule detection, can solve the problems of difficult discharge of needle tip bubbles and difficulty in filling glass needle tip nanopores, so that the properties of the solution will not change, and the filling rate and usage rate will be improved. , the effect of high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The first step, pre-filling preparation

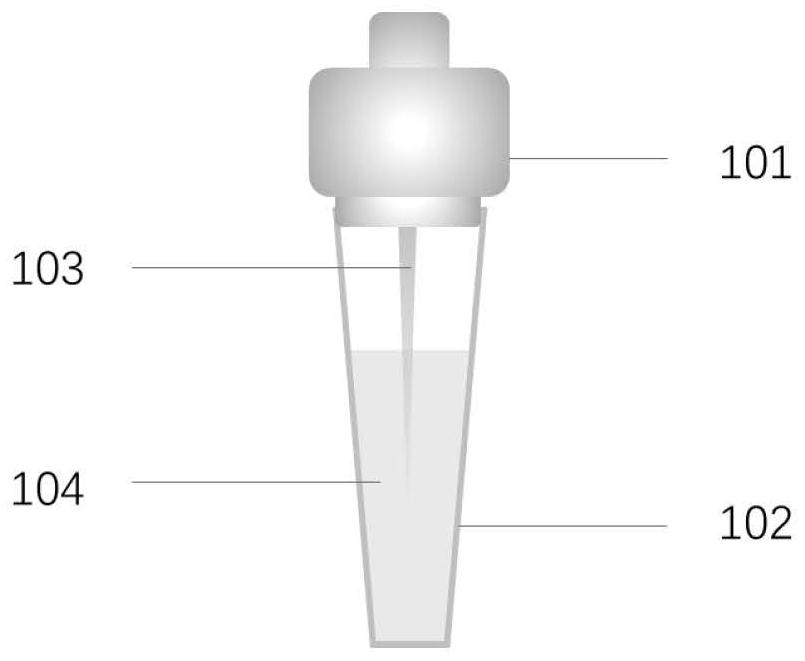

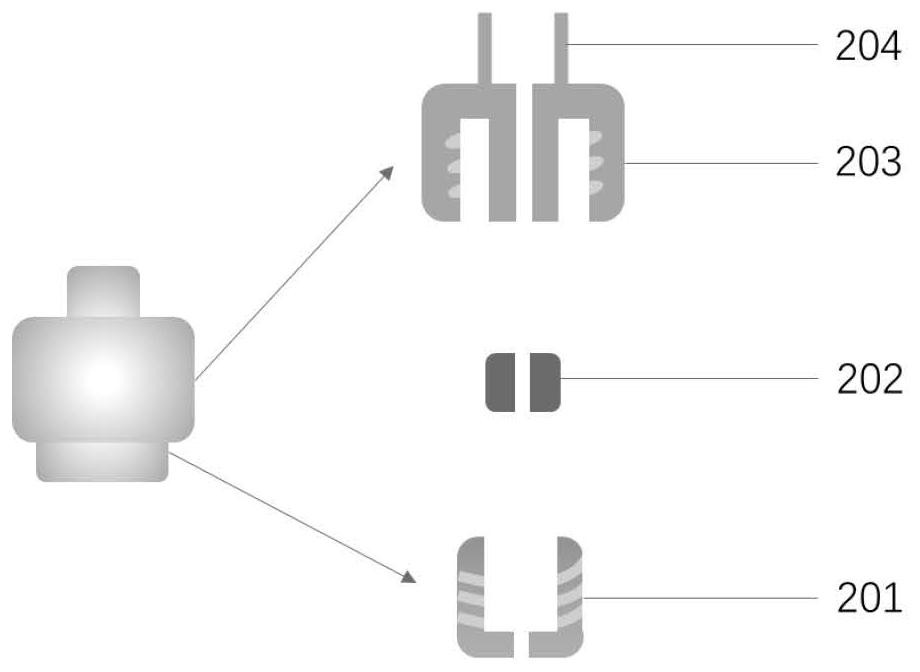

[0035]The quartz capillary with an outer diameter of 1.0 mm and an inner diameter of 0.7 mm was treated with piranha washing solution (volume ratio, 98% H2SO4: 30% H2O2 = 3: 1) for 30 minutes in a heated state, and then ultrasonically cleaned and rinsed with deionized water , blow dry with nitrogen, and dry at 60°C for 30 minutes, cool to room temperature, dry and store for later use; the glass tube 103 with a tip diameter of about 30 nm and a glass nanopore tip drawn by a P-2000 laser drawing machine , the glass tube 103 needle tip micrograph after drawing is shown in Figure 4 , using a micro-syringe to inject the required 1mol / L LiCl (pH=8) electrolyte solution 104 into the centrifuge tube 102; then, the glass tube 103 is fixed on the holder 101, and the upper part 203 of the needle tip does not exceed the liquid storage tank 204 bottom 201 , the holder 101 is inserted into the matching 1.5ml microcentrifuge tube 102 , and t...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 is that the solution 104 is replaced in the first step, and the specification of the quartz capillary is 1.0 mm in outer diameter and 0.5 mm in inner diameter. The diameter of the glass tip nanopore filled with the solution 104 is about 25nm, and the tip is fixed on the holder 101. The upper part 203 of the tip does not exceed the bottom 201 of the liquid tank 204, and the holder 101 is inserted into the matching 1.5ml microcentrifuge tube 102 , and dip the needle tip into the electrolyte solution 104 (1 nM λDNA, 1 mol / LLiCl, pH=8) containing the DNA sample.

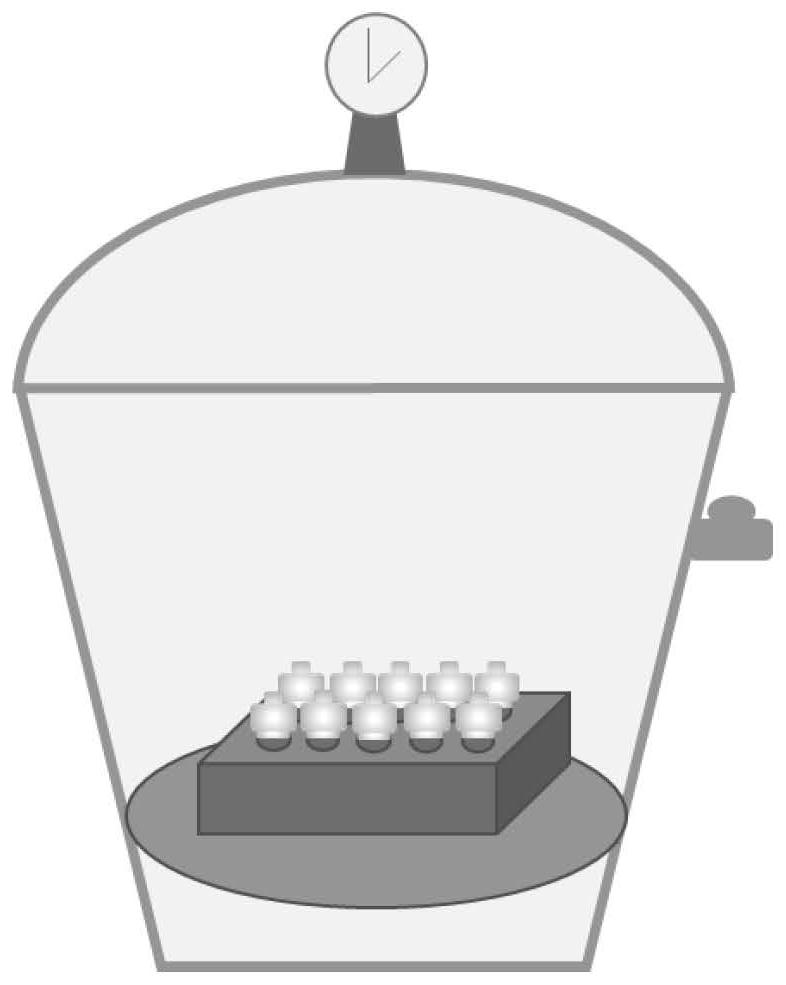

[0042] In the third step, seal the interface between the holder 101 and the centrifuge tube 102 with a parafilm, then place the centrifuge tube 102 on the shelf, put it in a vacuum desiccator, extract the vacuum, and observe the glass tube 103 in the process of vacuum removing air bubbles. The solution 104 inside overflows upwards, and the overflowing solution 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com