Method and apparatus for packing items, liquid or loose material in film bags, and a bag web

A technology for loose materials and articles, applied in the direction of liquid materials, solid materials, packaging, etc., to achieve the effects of safe guidance, lower prices, and increased filling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

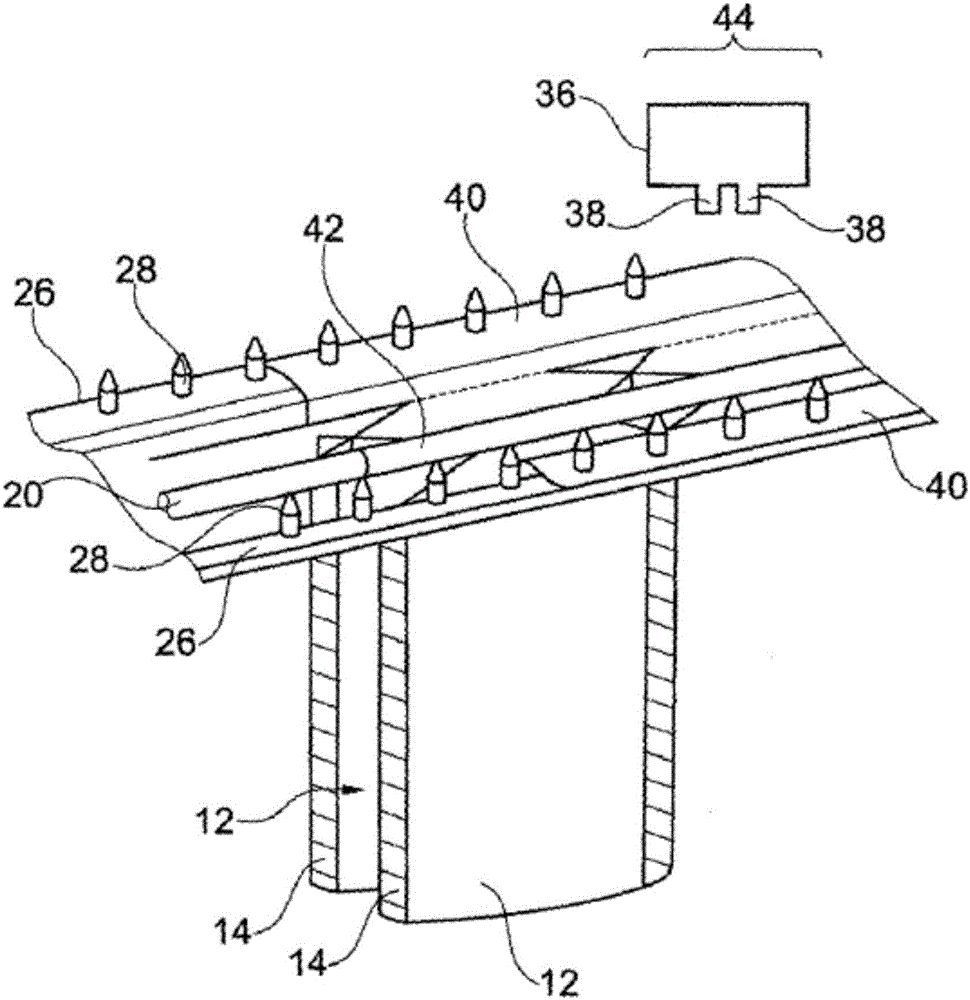

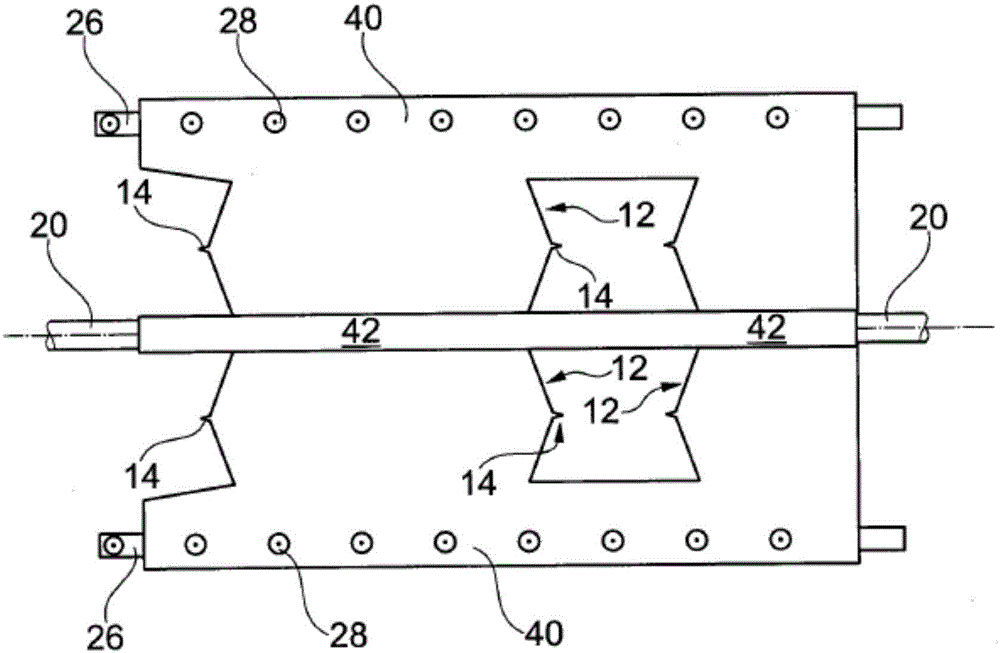

[0055] In the interpretation of the figures, the same designations will be used in different figures to provide the same or corresponding elements. Accordingly, an explanation of all details will not be given in connection with each individual figure / embodiment.

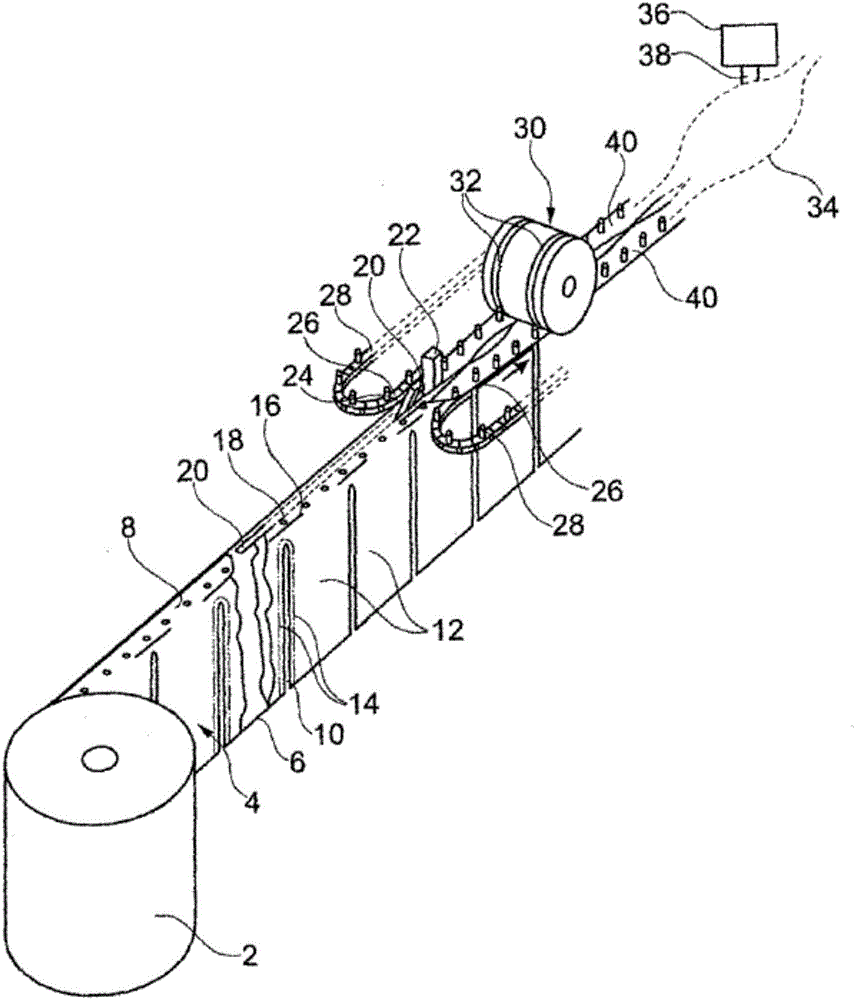

[0056] figure 1 The prior art is shown and used to explain the principles for designing the peripheral region at the outermost opposite bag opening edge and the guide member adapted to hold and guide the peripheral region at the opposite bag opening edge.

[0057] exist figure 1 As shown in , a web of film material 4 consisting of a double film folded around a bottom edge 6 and joined along an upper edge by a simple weld 8 without any kind of fold can be unrolled from a supply roll 2 or thicken. Therefore, it may also be a tubular membrane. There is a series of slits 10 in the film extending from the bottom edge 6 to a point below the upper edge 8 so that the web emerges with mutually separated bag items 12 whose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com