Box tofu filling system and method

A filling system and box tofu technology, applied in the field of tofu industrial production, to reduce air bubbles, improve filling speed, and overcome cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

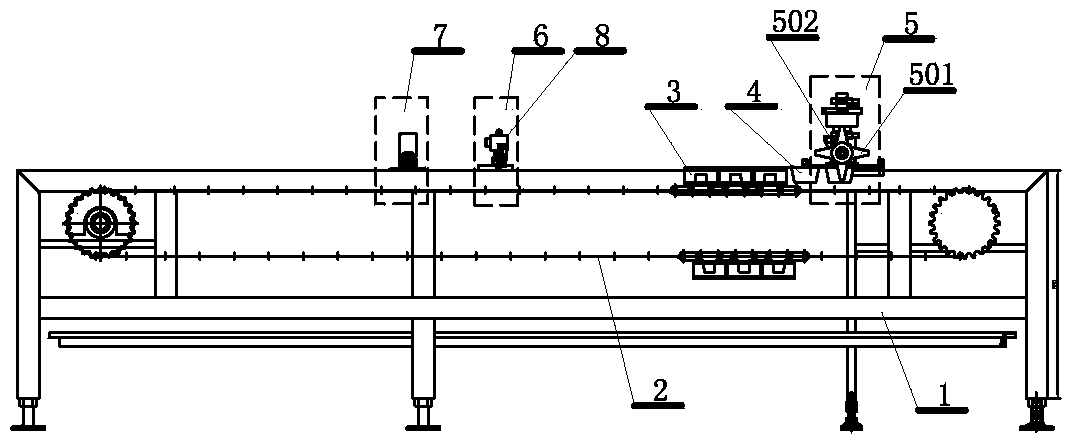

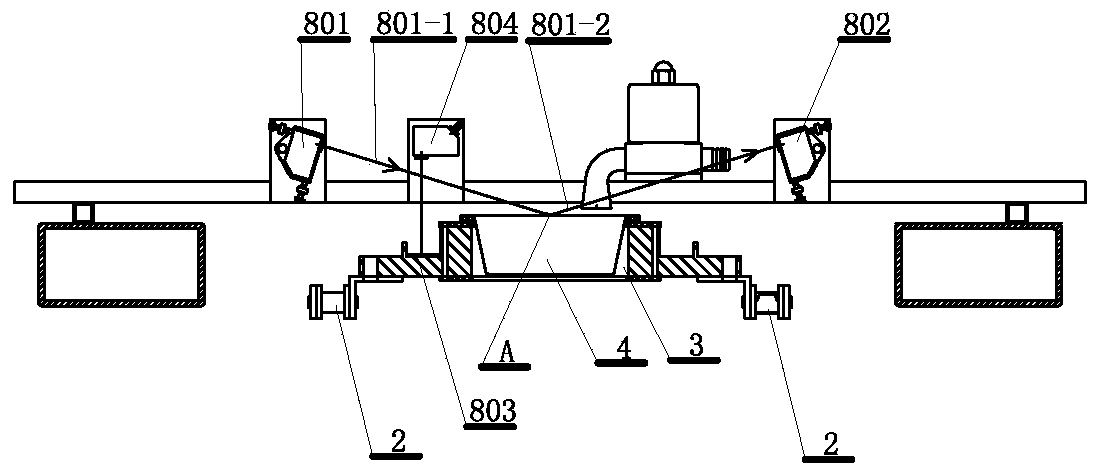

[0020] A box tofu filling system, such as figure 1 with figure 2 As shown, the system includes a frame 1, on which a bean curd box conveyor belt 2 is arranged, and the conveyor belt 2 is driven by chain shafts at both ends, and the tofu box placement slots 3 are sequentially arranged on the conveyor belt 2. A primary grouting section 5, a grout filling section 6 and a sealing section 7 for pouring soybean milk into the tofu box 4 are provided, and the conveyor belt carries the tofu box 4 through the primary grouting section 5, the grout filling section 6 and the sealing section 7 continuously and at a constant speed. , the soybean milk poured into the tofu box 4 by the grouting nozzle in the primary grouting section 5 is not full of the tofu box, and the grout filling nozzle in the grouting section 6 pours soybean milk into the tofu box 4 moved from the primary grouting section 5 to fill the tofu box , and then the tofu box 4 full of soy milk is sealed by the sealing section...

Embodiment 2

[0034] A box of bean curd filling method, this embodiment is based on the method of the embodiment 1 system, so the structural features described in embodiment 1 are applicable to this embodiment, and if any structures involved in this embodiment are not included in embodiment 1 The related content is also applicable to embodiment 1. The method includes primary grouting and secondary grouting, wherein the primary grouting is to pour soybean milk into an empty tofu box carried on a tofu box conveyor belt, and the level of the injected soybean milk is lower than that of a full box of soybean milk, Usually it is 10 to 15 mm lower than the full box state, and the secondary grouting is to continue grouting to the bean curd box that is conveyed from the conveyor belt and through the primary grouting to supplement the soymilk.

[0035] Wherein: the primary grouting adopts the grouting method of timing quantitative pump, and the flow of the quantitative pump is controlled by adjusting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com