Method and filling installation for filling a hydrogen gas into a vessel

A technology for containers and hydrogen, which is applied in the equipment for loading pressure vessels, filling methods for containers, and installation devices for container structures, etc., can solve the problems of uncontrolled hydrogen temperature, gas outflow, and loss of precious gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the drawings, the same components or components with similar functions are denoted by the same reference numerals.

[0038] In the present description and claims, the term "container" includes all types of storage containers that hold hydrogen gas or fluid in liquid form at a pressure different from the ambient pressure.

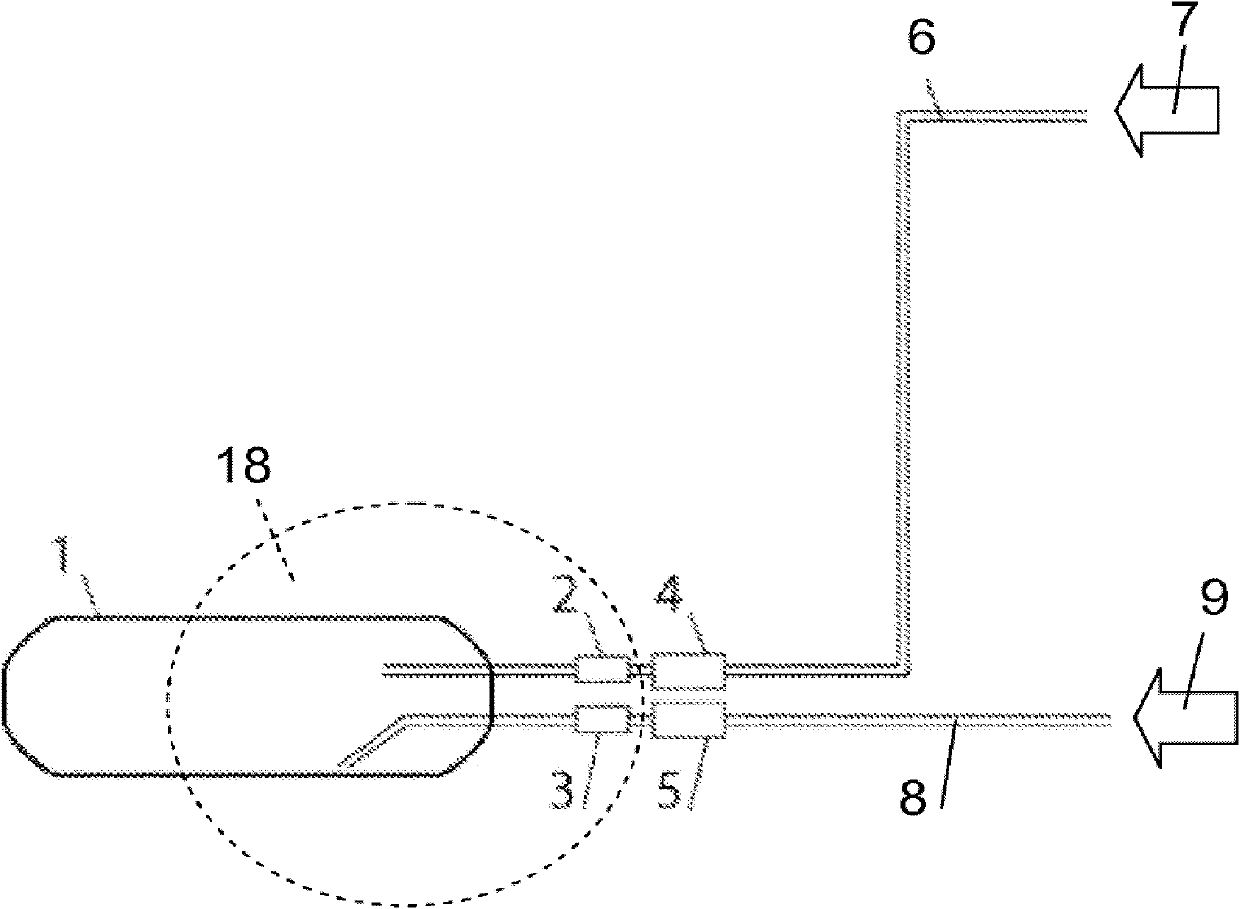

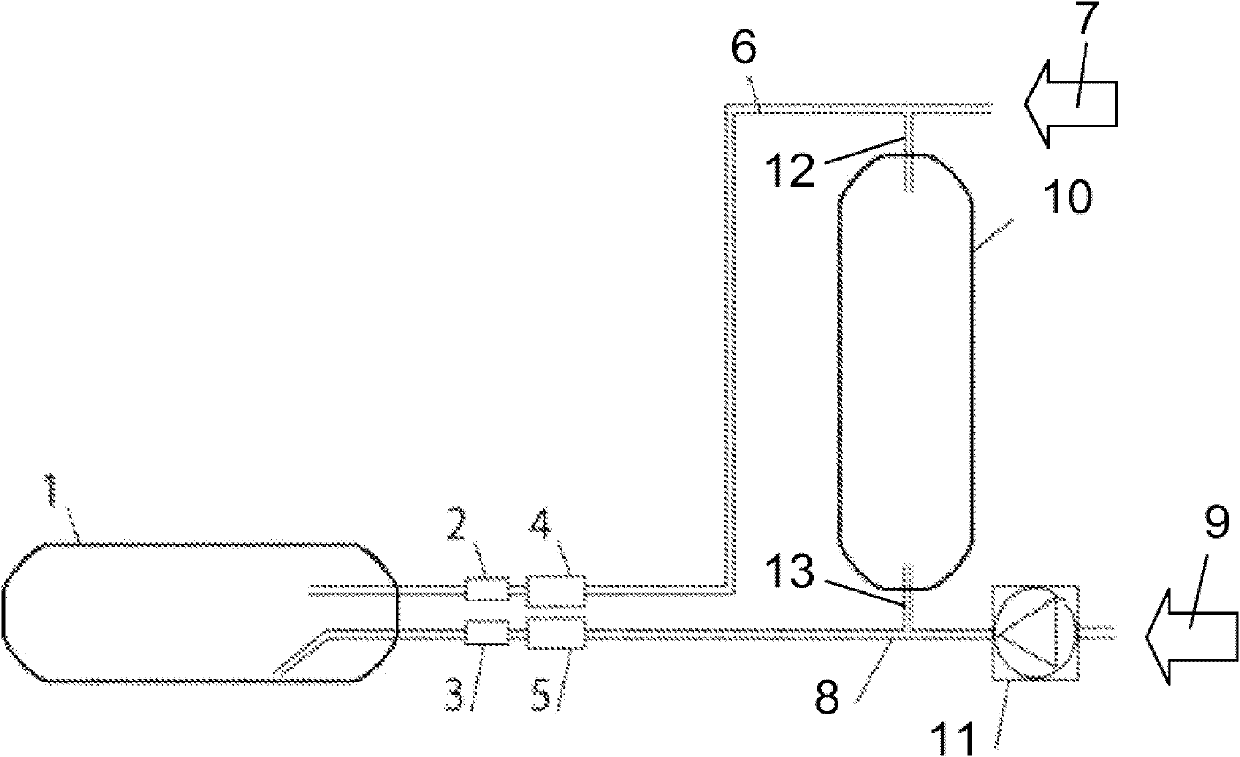

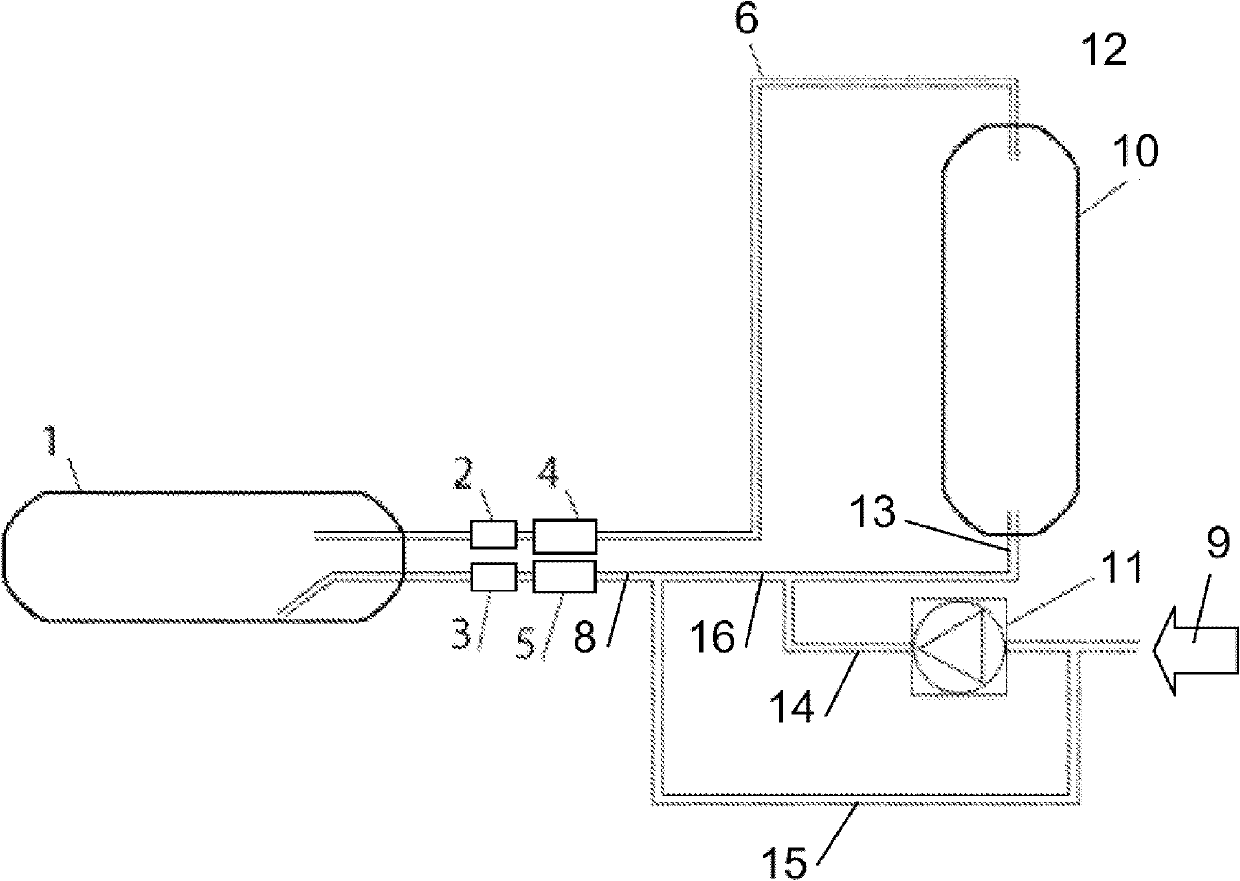

[0039] figure 1 It is a schematic diagram of a container 1, such as a hydrogen fuel storage tank or a hydrogen cylinder installed in a vehicle. The container 1 has a first port 2 for gas to pass through and a second port 3 for liquid to pass through, wherein the second port 3 is connected to the The first port 2 is separated from which, in the embodiment shown, the second port 3 is separated by a large or remote distance.

[0040] Such as figure 1 As shown, when the container 1 is placed in the working position, the second port 3 terminates in the container 1 , preferably below the end of the first port 2 located in the container 1 . The two por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com