Fiber reinforced composite material high-pressure gas bottle with superconduction radiating device

A technology of high-pressure gas cylinder and heat-dissipating device, which is applied in the direction of equipment loaded into pressure vessel, installation device of vessel structure, pressure vessel, etc., can solve the problems of thermal conductivity limiting heat transfer efficiency, reducing heat transfer efficiency, heat loss, etc. Achieve the effect of high filling rate, wide adaptability and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

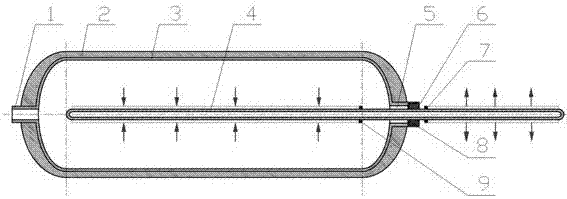

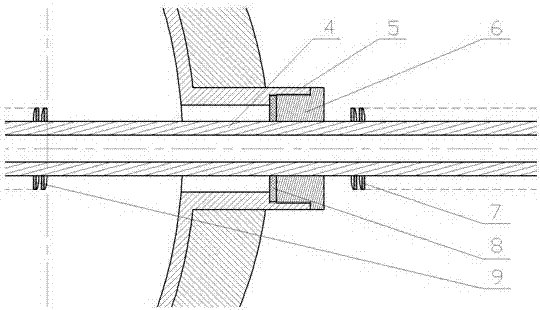

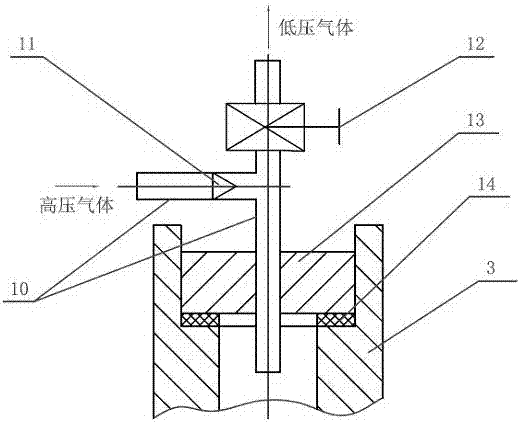

[0027] like figure 1 , figure 2 , image 3 As shown, the inner liner 3 of the high-pressure gas cylinder of the present invention is surrounded by a fiber winding layer 2, and one end of the high-pressure gas cylinder has an air inlet and outlet 1, and the other end of the high-pressure gas cylinder has an opening 5, which is exposed on the high-pressure gas cylinder. One end of the outer opening 5 is threadedly connected to the opening end cap 6, and an opening sealing gasket 8 is provided between the opening end cap 6 and the opening 5, and one end of the superconducting heat pipe 4 passes through the opening end cap 6 central hole through the opening sealing gasket 8 Insert into the high-pressure gas cylinder, the other end of the superconducting heat pipe 4 is located outside the high-pressure gas cylinder, the superconducting heat pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com