Quickly-formed rubber strip production method and device

A production method and technology for rubber strips, which are applied in the field of rapid prototyping rubber strip production methods and equipment, can solve the problems of difficulty in guaranteeing rubber strip specifications, long time for producing sheet rubber, slow production efficiency, etc. The effect of plasticizing elasticity and fast molding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A rapid prototyping rubber strip production method and equipment thereof, the rapid prototyping rubber strip production method comprising:

[0032] ① Weigh the rubber raw material and send it into the internal mixer, and add vulcanizing agent at the same time for mixing;

[0033] ②Press and roll the mixed rubber obtained by kneading to obtain rolled sheet rubber;

[0034] ③The rolled sheet rubber is stuffed into the rubber extrusion equipment. The temperature inside the rubber extrusion equipment is 70°C. After the rubber is extruded longitudinally, it is cooled by spraying cooling water twice to obtain rubber strips. The temperature of the cooling water is 5°C;

[0035] ④ After cooling the extruded rubber strips, they are sent to a cutting machine, and after the rubber strips are cut longitudinally, the finished rubber strips are obtained.

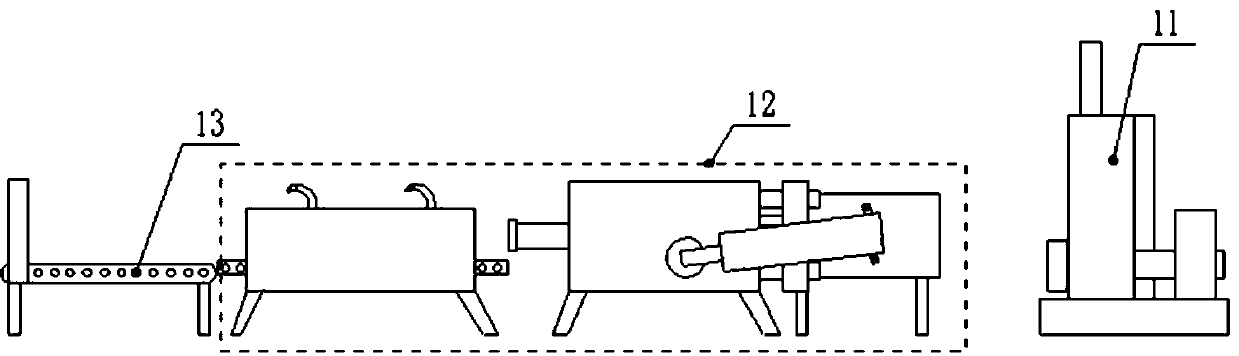

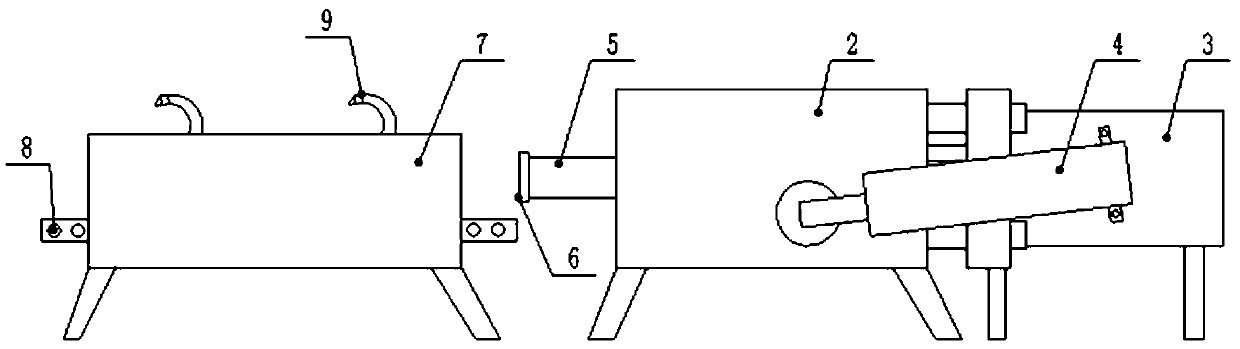

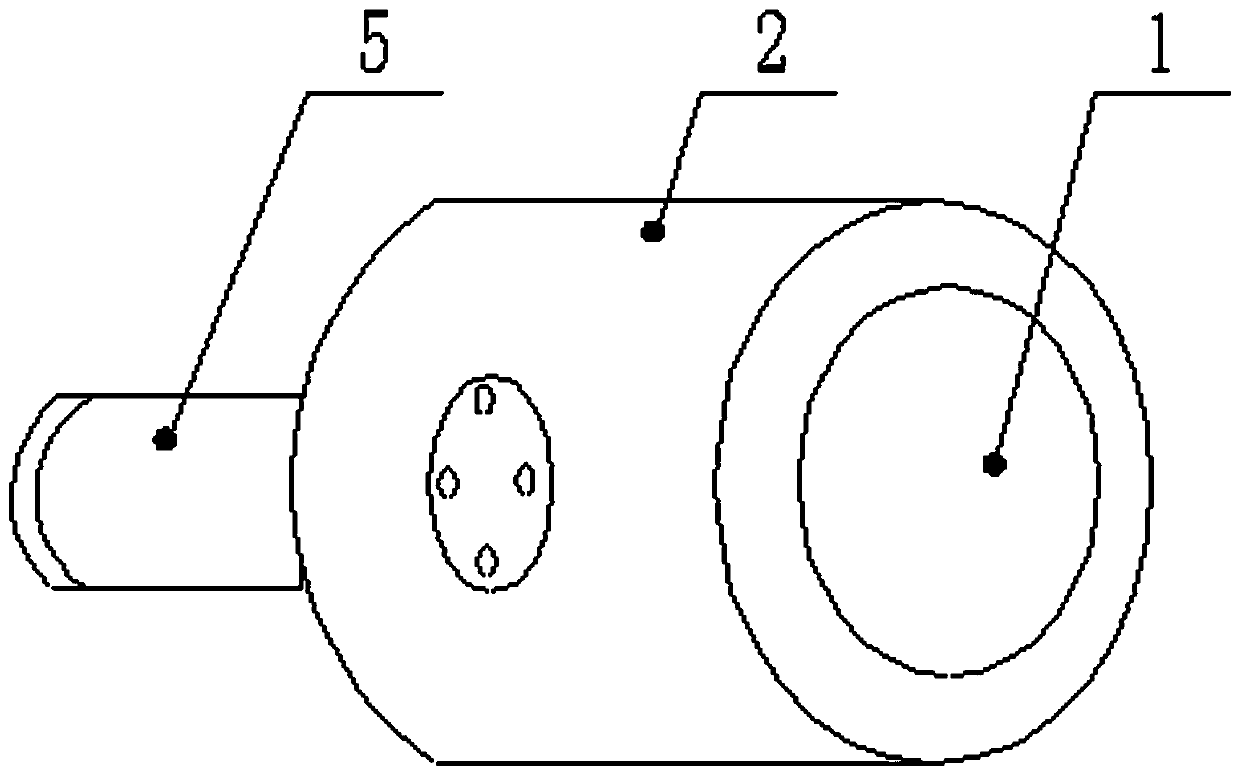

[0036] The rapid prototyping rubber strip production equipment includes an internal mixer, rubber extruding equipment and a cutt...

Embodiment 2

[0040] A rapid prototyping rubber strip production method and equipment thereof, the rapid prototyping rubber strip production method comprising:

[0041] ① Weigh the rubber raw material and send it into the internal mixer, and add vulcanizing agent at the same time for mixing;

[0042] ②Press and roll the mixed rubber obtained by kneading to obtain rolled sheet rubber;

[0043] ③The rolled sheet rubber is stuffed into the rubber extrusion equipment. The temperature inside the rubber extrusion equipment is 85°C. After the rubber is extruded longitudinally, it is cooled by spraying cooling water twice to obtain rubber strips. The temperature of the cooling water is 8°C;

[0044] ④ After cooling the extruded rubber strips, they are sent to a cutting machine, and after the rubber strips are cut longitudinally, the finished rubber strips are obtained.

[0045] The rapid prototyping rubber strip production equipment includes an internal mixer, rubber extruding equipment and a cutt...

Embodiment 3

[0049] A rapid prototyping rubber strip production method and equipment thereof, the rapid prototyping rubber strip production method comprising:

[0050] ① Weigh the rubber raw material and send it into the internal mixer, and add vulcanizing agent at the same time for mixing;

[0051] ②Press and roll the mixed rubber obtained by kneading to obtain rolled sheet rubber;

[0052] ③The rolled sheet rubber is stuffed into the rubber extrusion equipment. The temperature inside the rubber extrusion equipment is 90°C. After the rubber is extruded longitudinally, it is cooled by spraying cooling water twice to obtain rubber strips. The temperature of the cooling water is 10°C;

[0053] ④ After cooling the extruded rubber strips, they are sent to a cutting machine, and after the rubber strips are cut longitudinally, the finished rubber strips are obtained.

[0054] The rapid prototyping rubber strip production equipment includes an internal mixer, rubber extruding equipment and a cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com