Analysis method for foil elongation size effect

A technology of size effect and analysis method, applied in the direction of analyzing materials, testing material strength using stable tension/pressure, measuring devices, etc., can solve the problem of high scrap rate, inability to use the best plastic state of foil, restricting foil forming Process application and development and other issues to achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

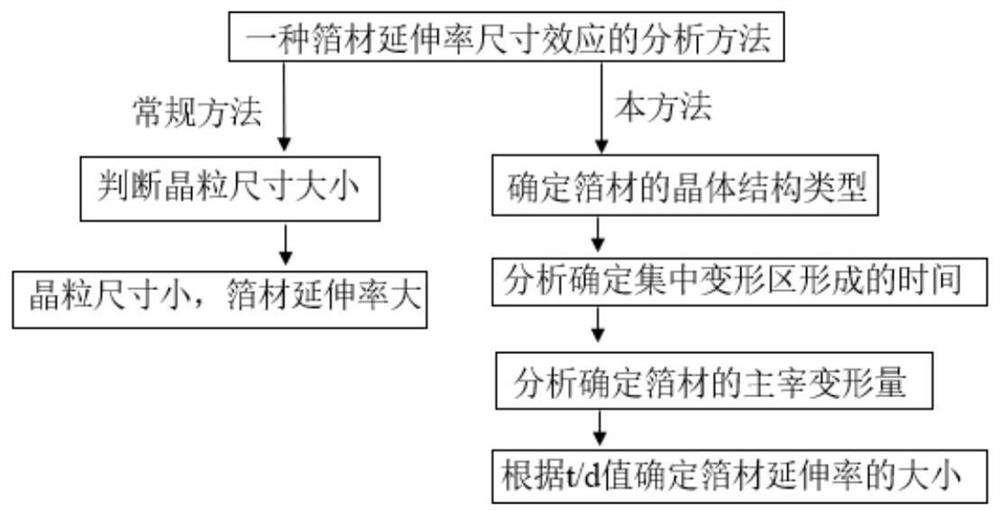

[0018] Such as figure 1 As shown, according to a method for analyzing the size effect of foil elongation in a preferred embodiment of the present invention, the specific implementation is as follows:

[0019] Step 1: Determine the crystal structure type of the foil;

[0020] Step 2: Analyze and determine the time when the concentrated deformation zone is formed;

[0021] Step 3: Analyze and determine the dominant deformation of the foil;

[0022] Step 4: Determine the elongation of the foil according to the t / d value.

[0023] In the first step, the crystal structure of the foil is hexagonal close-packed lattice or face-centered cubic lattice.

[0024] In the second step, the concentrated deformation zone of the hexagonal close-packed lattice foil is formed early, and the concentrated deformation zone of the face-centered cubic lattice foil is formed late.

[0025] In the third step, the dominant deformation amount of the hexagonal close-packed lattice foil material is con...

Embodiment 1

[0028] Taking the TC1 foil with a grain size of about 3 μm, 5 μm, and 15 μm and a thickness of 50 μm as an example, the implementation process of the method proposed in the present invention to analyze the size effect of the elongation of the foil is described, as follows:

[0029] (1) Determine the crystal structure type of TC1 foil as a close-packed hexagonal crystal structure;

[0030] (2) The concentrated deformation zone of TC1 foil is formed early;

[0031] (3) The concentrated deformation of TC1 foil is the dominant deformation;

[0032] (4) The t / d value of the TC1 foil with a grain size of 15 μm is small, and the individual grain size is large.

[0033] Therefore, the TC1 foil with a grain size of 15 μm has a large amount of concentrated deformation and a large elongation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com