Quick granule producing machine

A granulator and granule technology, which is applied in the direction of raw material extrusion granulation, press, material forming press, etc., can solve the problems of inconvenient cleaning, excessive powder production, and affecting the quality of medicines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

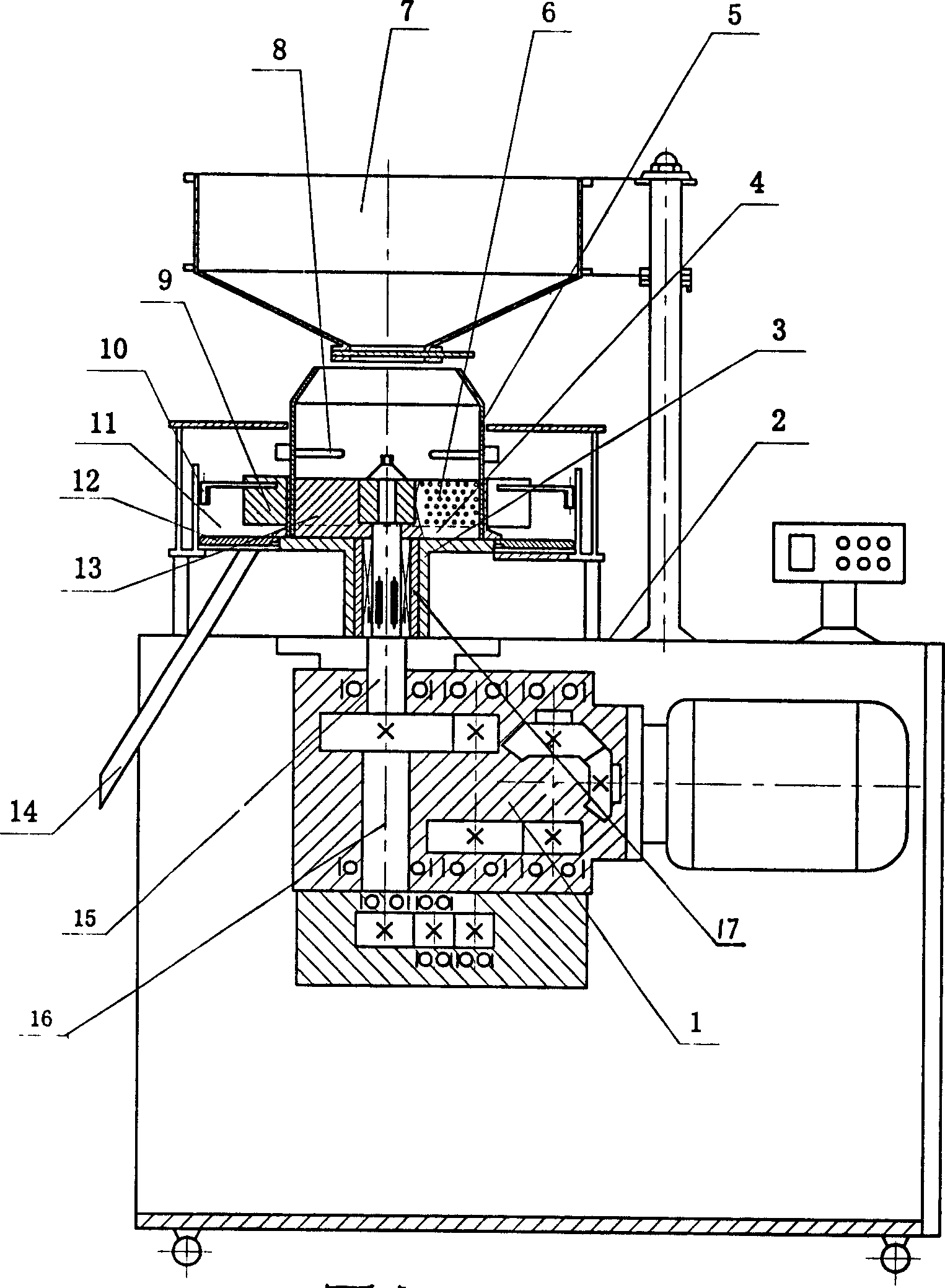

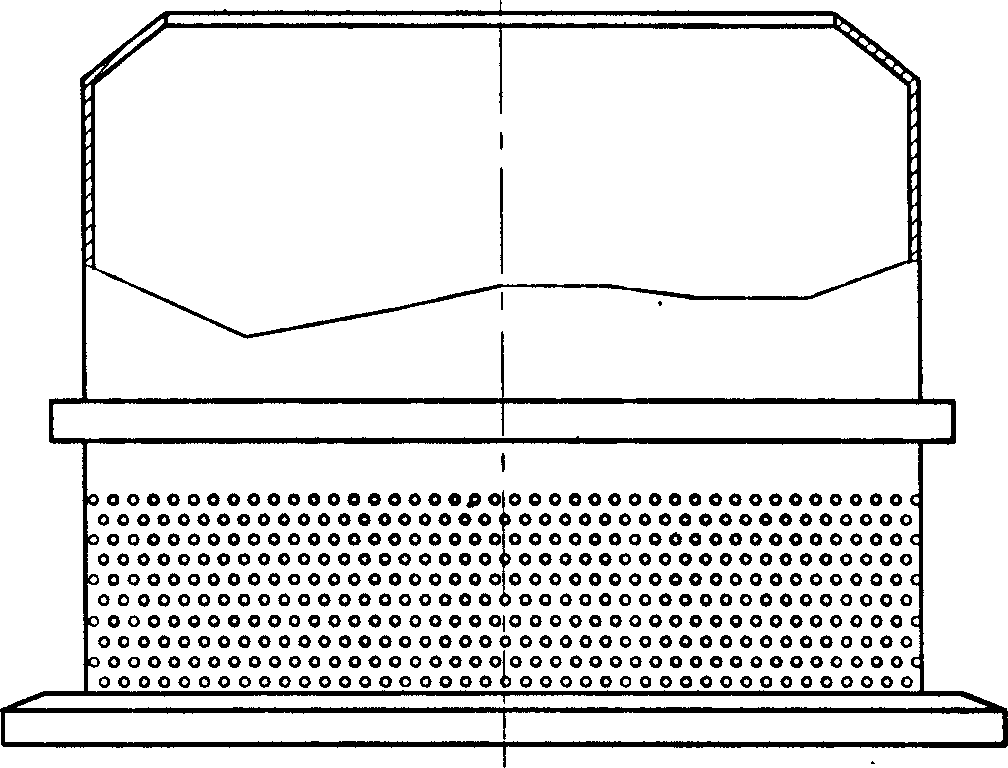

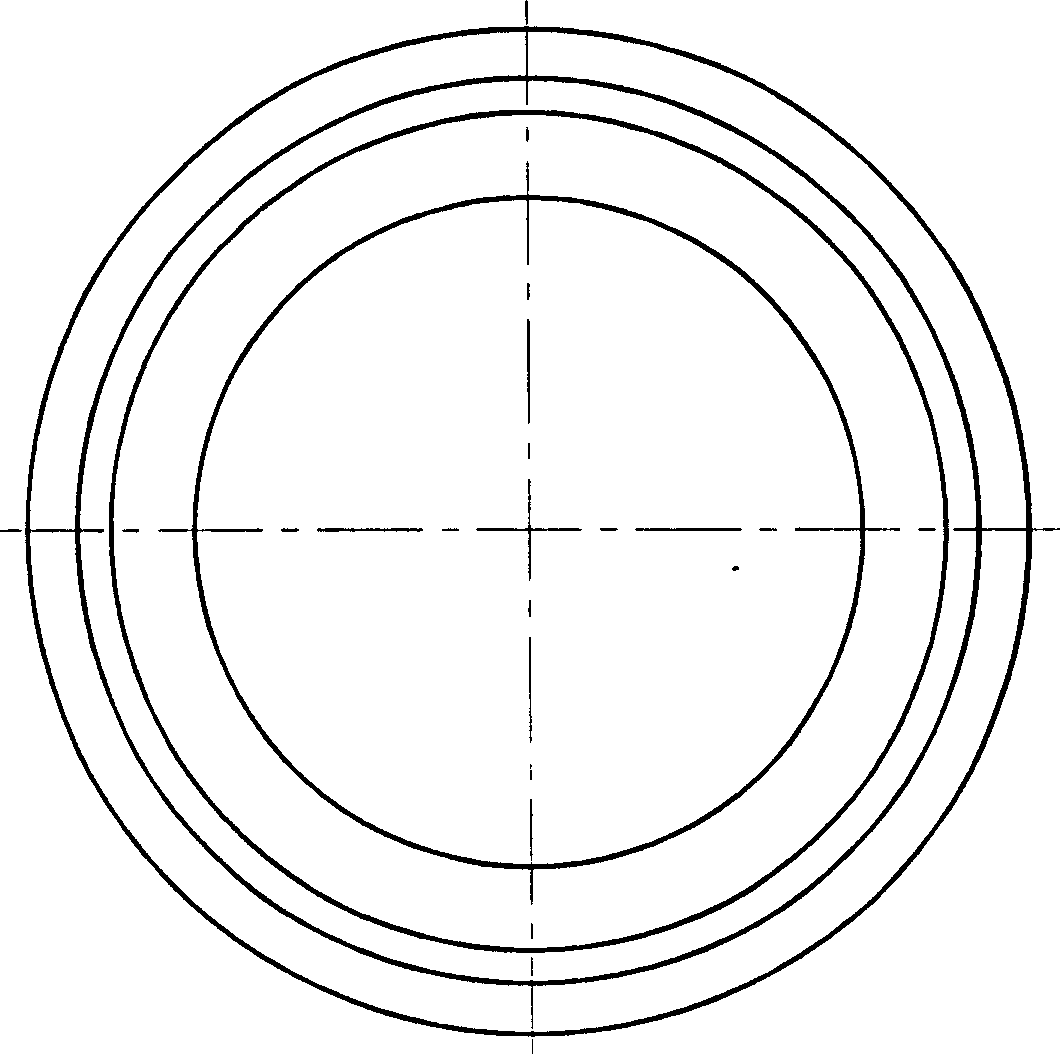

[0010] The accompanying drawings have shown the structure of the present invention and its embodiments, and further describe the relevant details of the embodiments below in conjunction with the accompanying drawings. The whole machine includes a hopper, a deceleration device, a stirring and rotating granulating mechanism, a transport trough and a discharge port. The hopper (7) is installed on the column of the frame, and the hopper (7) can rotate 360° in the radial direction. When the hopper nozzle is aligned with the upper feeding port of the screen cylinder, and locked with the rail, the material can be unloaded after opening the gate. The reduction mechanism (1) adopts planetary transmission, and the reduction mechanism is equipped with a hard-toothed helical gear to increase the torque. And wear resistance, through the motor under the frequency conversion of the frequency converter, the speed can be continuously variable. The stirring and rotating granulating mechanism ut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com