Environment-friendly nitrogen potassium dressing fertilizer containing various nitrogen elements and preparation method thereof

A green and environmentally friendly topdressing fertilization technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problem of high ammonia toxicity and achieve the effects of less dust, low temperature and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

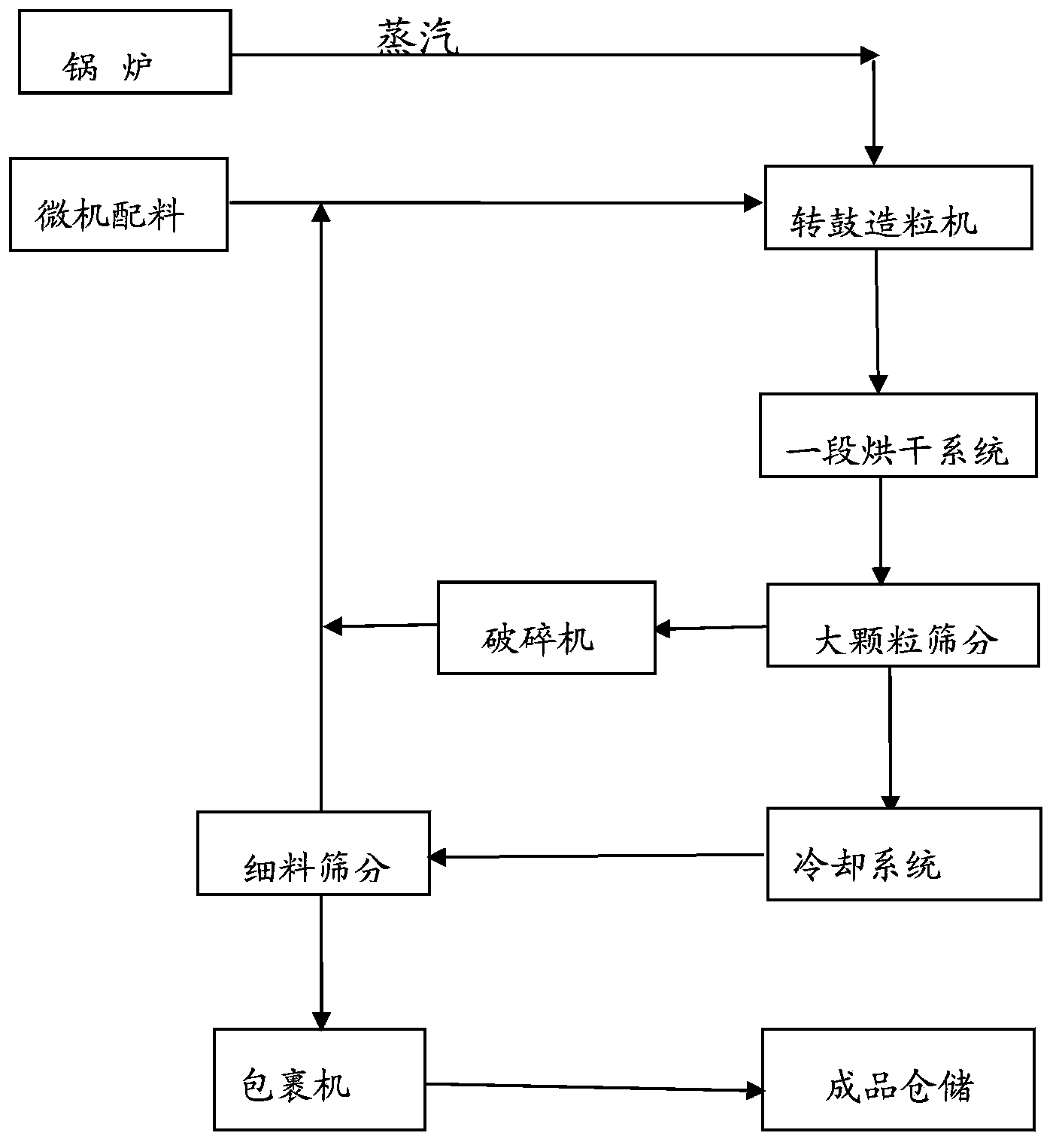

[0033] The preparation method of the above-mentioned green and environment-friendly nitrogen and potassium topdressing fertilizer containing various nitrogen elements comprises the following steps:

[0034] (1) In the production of compound fertilizer by pellet method, urea, ammonium bicarbonate, ammonium sulfate, potassium nitrate, potassium chloride, humic acid, sepiolite, calcium hydroxide and other materials containing trace elements and plant growth regulators are passed through After the microcomputer metering, it enters the drum granulator. During the granulation process, the viscosity of urea nitrate and sepiolite produced by the reaction of potassium nitrate and urea is used as the adhesive, and the water produced by the decomposition of ammonium bicarbonate is used as the liquid phase. The ammonia gas produced by the decomposition of ammonium bicarbonate completes the ammonification treatment of potassium nitrate to control the quality of urea nitrate produced by the ...

Embodiment 1

[0044] Embodiment 1: 22-0-10 rice topdressing, taking 1 ton of product raw material consumption quota as an example:

[0045] Add 365 kg of urea (containing N46.2%, mass percentage, the same below), 60 kg of ammonium bicarbonate (containing N17%), 130 kg of ammonium sulfate (containing N21%, containing sulfur) and potassium nitrate (containing N13 .5%, K 2 O46%) 120 kg, potassium chloride (containing K 2 O60%) 80 kg, humic acid (organic matter content ≧ 60%) 70 kg, sepiolite (containing magnesium, silicon) 90 kg, calcium hydroxide (calcium oxide content ≧ 50%) 60 kg, zinc sulfate (containing sulfur, Zinc) 20 kg, sodium nitrophenolate 5 kg, the above materials are mixed in the drum granulator, using the viscosity of urea nitrate and sepiolite and the water produced by the decomposition of ammonium bicarbonate as the liquid phase required for granulation, through Add steam to increase the temperature of the material and supplement the amount of liquid phase required for granul...

Embodiment 2

[0046] Embodiment 2: 20-0-15 corn topdressing, taking 1 ton of product raw material consumption quota as an example:

[0047] Add 340 kg of urea (containing N46.2%, mass percentage, the same below), 50 kg of ammonium bicarbonate (containing N17%), 105 kg of ammonium sulfate (containing N21%, containing sulfur) and potassium nitrate (containing N13 .5%, K 2 O46%) 100 kg, potassium chloride (containing K 2 O60%) 175 kg, humic acid (organic matter content ≧ 60%) 70 kg, sepiolite (containing magnesium, silicon) 80 kg, calcium hydroxide (calcium oxide content ≧ 50%) 50 kg, manganese sulfate (containing sulfur, Manganese) 15 kg, ferrous sulfate (containing sulfur, iron) 10 kg, compound sodium nitrophenolate 5 kg, the above materials are mixed in the drum granulator, and produced by the viscosity of urea nitrate and sepiolite and the decomposition of ammonium bicarbonate The water is used as the amount of liquid phase required for granulation. By adding steam to increase the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com