Slag quenching system and process

A technology for water quenching and steel slag, which is applied in the field of steel slag water quenching system and process, can solve the problems of explosion, steel slag falling into strands, and cannot be evenly distributed, and achieves the effects of improving granulation rate, avoiding explosion and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

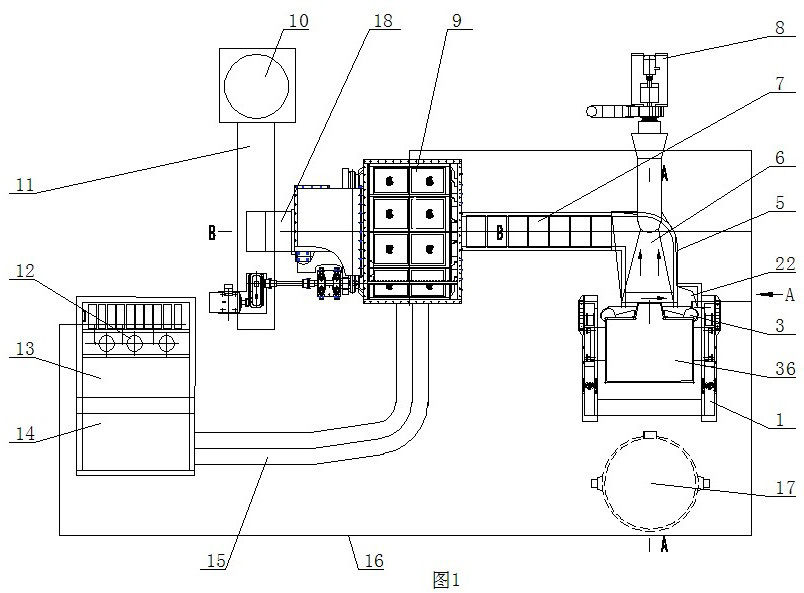

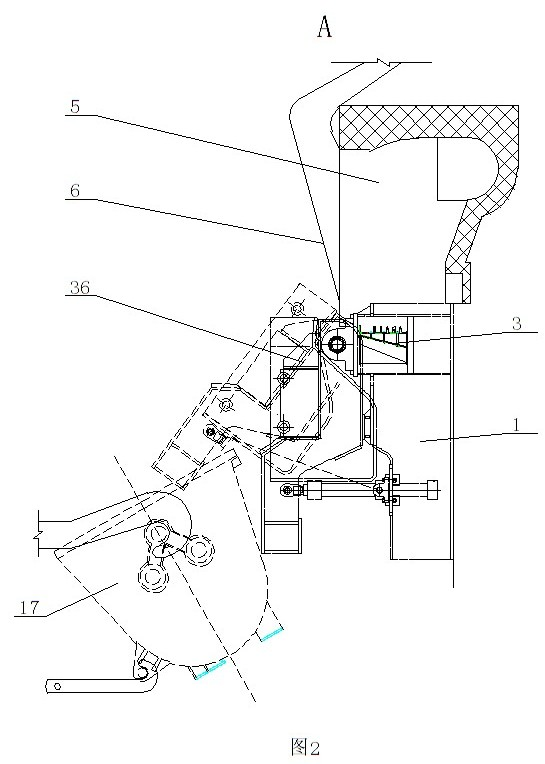

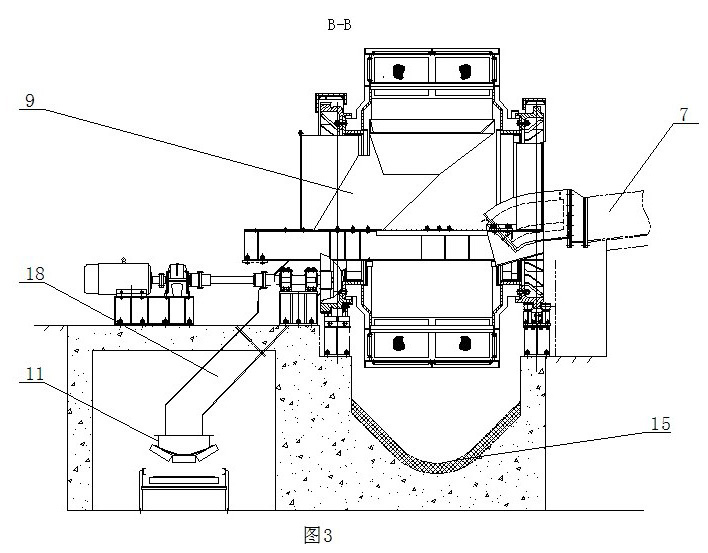

[0013] The steel slag water quenching system of the present invention comprises a tundish tank tipping device (1), a tundish tank (36) is installed on the tundish tank tipping device (1), and a tundish tank (36) is installed on the side wall There is a slag outlet (2), and the slag outlet (2) is composed of vertical plates on both sides connected to the bottom plate, wherein the bottom plate is flat, and the flat bottom plate can spread the steel slag flowing to the tundish (36) as flat as possible open, so that the steel slag falls like a water curtain, and the thickness is small, which is convenient for the water mist of the granulator (3) to fully cut and granulate the steel slag during the falling process. The water mist of the granulator (3) is difficult to fully cut and granulate; the granulator (3) is installed at the front of the tundish tilting device (1), and the granulator (3) is located under the slag outlet (2). It is convenient to water-quench the steel slag flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com