Pakchoi organic composite fertilizer

A compound fertilizer and Chinese cabbage technology, applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems of soil nutrient accumulation, out-of-absorption, and nutrient entry, etc., to promote metabolism, prevent dampness, and improve The effect of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

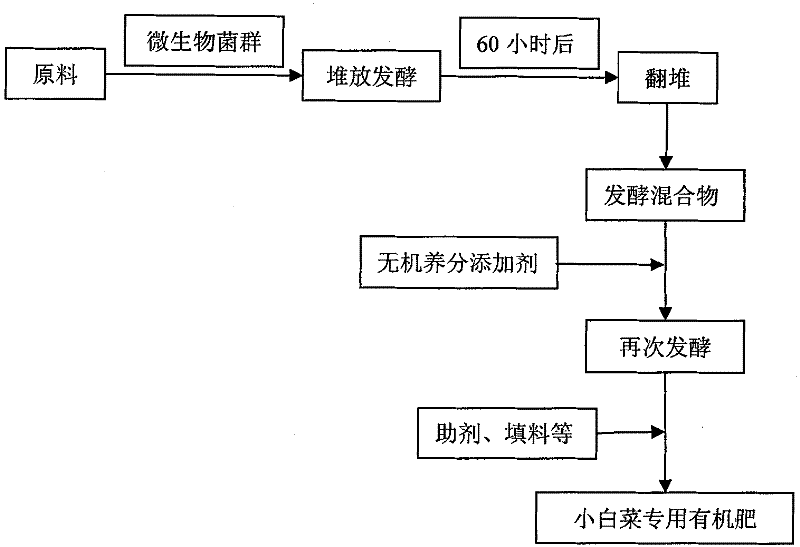

Method used

Image

Examples

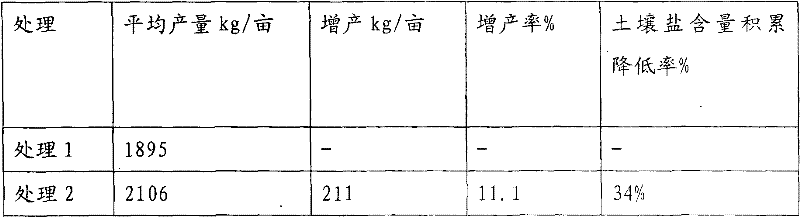

Embodiment 1

[0026] Select by weight 45 parts of a mixture of duck manure, sheep manure, cow manure, fresh vermicompost and peanut cake, 2 parts of calcium nitrate, 1 part of potassium nitrate, 1 part of magnesium nitrate, 3 parts of ammonium nitrate, potassium dihydrogen phosphate 2 parts, 2 parts of chelated iron, 3 parts of boric acid, 1 part of manganese sulfate, 0.5 parts of zinc sulfate, 1 part of copper sulfate, 3 parts of ammonium molybdate, 2 parts of potassium chloride, 1 part of ferrous sulfate, 1.5 parts of sodium molybdate 1 part of sodium selenite, 3 parts of humic acid, 5 parts of rare earth, 4 parts of diatomaceous earth, 3 parts of 100 mesh attapulgite, 2 parts of EM effective microbial group, 10 parts of urea, 5 parts of plant ash, 3 parts of bran share;

[0027] According to the order of addition, the mixture of duck manure, sheep manure, cow manure, fresh vermicompost and peanut cake will be added to EM effective microbial flora, stacked and fermented, covered with moi...

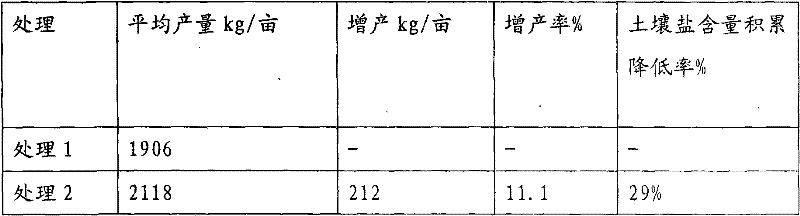

Embodiment 2

[0040] Select by weight 50 parts of a mixture of duck manure, sheep manure, cow manure, fresh vermicompost and peanut cake, 3 parts of calcium nitrate, 2 parts of potassium nitrate, 1.5 parts of magnesium nitrate, 4 parts of ammonium nitrate, potassium dihydrogen phosphate 3 parts, 6 parts of chelated iron, 3.5 parts of boric acid, 1 part of manganese sulfate, 1 part of zinc sulfate, 2 parts of copper sulfate, 4 parts of ammonium molybdate, 5 parts of potassium chloride, 2 parts of ferrous sulfate, 3 parts of sodium molybdate 1 part of sodium selenite, 6 parts of humic acid, 7 parts of rare earth, 4 parts of filler, 6 parts of additives, 4 parts of beneficial microbial flora, 17 parts of urea, 8 parts of plant ash, 4 parts of bran;

[0041] According to the order of addition, the mixture of duck manure, sheep manure, cow manure, fresh vermicompost and peanut cake will be added to the EM effective microbial flora, stacked and fermented, and covered with thermal insulation materi...

Embodiment 3

[0054] Select by weight 60 parts of a mixture of duck manure, sheep manure, cow manure, fresh vermicompost and peanut cake, 5 parts of calcium nitrate, 3.5 parts of potassium nitrate, 2 parts of magnesium nitrate, 5 parts of ammonium nitrate, potassium dihydrogen phosphate 4 parts, 8 parts of chelated iron, 4 parts of boric acid, 1.5 parts of manganese sulfate, 1.5 parts of zinc sulfate, 2.5 parts of copper sulfate, 6 parts of ammonium molybdate, 7 parts of potassium chloride, 3 parts of ferrous sulfate, 4 parts of sodium molybdate 2 parts of sodium selenite, 4 parts of humic acid, 10 parts of rare earth, 4 parts of filler, 1 part of additive, 5 parts of beneficial microbial flora, 25 parts of urea, 10 parts of plant ash, 6 parts of bran;

[0055] According to the order of addition, the mixture of duck manure, sheep manure, cow manure, fresh vermicompost and peanut cake will be added to the EM effective microbial flora, stacked and fermented, covered with moisturizing and heat-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com