Polypeptide composite fertilizer and its production

A preparation process and technology of compound fertilizer, applied in the directions of urea compound fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problems of unreasonable process structure, unable to exert the effect of increasing fertilizer, complicated production process, etc., and achieve improved soil structure and good economic prospects. and social benefits, the effect of improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

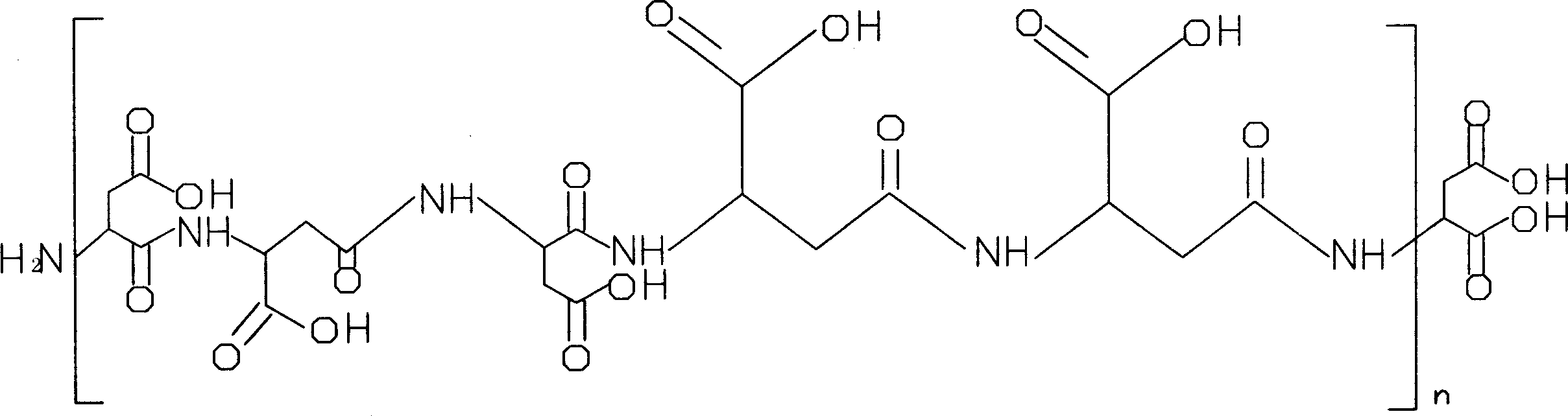

[0038] Embodiment 1, a kind of polypeptide compound fertilizer, is added with polyaspartic acid or its salt in the described compound fertilizer, as shown in the figure, described polyaspartic acid or its salt molecular weight is 1500-5000, from this structure It can be seen that it has a very strong chelating ability for metal ions, and because it has the peptide bond properties of proteins, it not only has a strong adsorption ability for cations, but also has a strong adsorption ability for anions, and it is non-toxic, harmless, and has no residue. Biodegradable.

[0039] It can also be seen from the structural formula that not only the internal gene -COOH, but also the gene groups -COOH and -NH at the end 2 It can still chelate various anions and cations, which also lays the foundation for the strong adsorption capacity of the polymeric amino acid, and polyaspartic acid or its salt has good water solubility, easy to decompose and absorb, and polyaspartic acid or The salt a...

Embodiment 2

[0051] Embodiment 2, a kind of polypeptide compound fertilizer, is added with polyaspartic acid or its salt in the described compound fertilizer, as shown in the figure, described polyaspartic acid or its salt molecular weight is 1500-5000, from this structure It can be seen that it has a very strong chelating ability for metal ions, and because it has the peptide bond properties of proteins, it not only has a strong adsorption ability for cations, but also has a strong adsorption ability for anions, and it is non-toxic, harmless, and has no residue. Biodegradable.

[0052] It can also be seen from the structural formula that not only the internal gene -COOH, but also the gene groups -COOH and -NH at the end 2 It can still chelate various anions and cations, which also lays the foundation for the strong adsorption capacity of the polymeric amino acid, and polyaspartic acid or its salt has good water solubility, easy to decompose and absorb, and polyaspartic acid or The salt a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com