Method for treating fermentative pharmaceutical wastewater

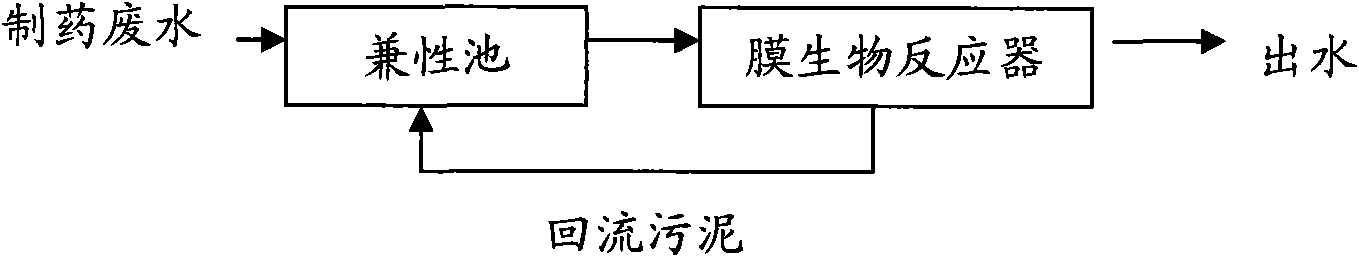

A technology for pharmaceutical wastewater and wastewater, which is applied in natural water treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems of high operating cost, low treatment process efficiency, complicated operation, etc., and improve the treatment effect , reduce the cost of sludge disposal, and increase the effect of microbial biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The wastewater to be treated is lincomycin wastewater, the hydraulic retention time of the facultative pool is 20 hours, the hydraulic retention time of the membrane bioreactor is 8 hours, the sludge concentration of the biochemical system is controlled at 15000-20000mg / L, and the sludge reflux is set in the reactor pump to return the mud-water mixture in the reactor to the facultative tank, and the return ratio is 100%. And use hollow fiber membrane modules for mud-water separation.

Embodiment 2

[0016] The wastewater to be treated is penicillin wastewater, the hydraulic retention time of the facultative pool is 20 hours, the hydraulic retention time of the membrane bioreactor is 12 hours, the sludge concentration of the biochemical system is controlled at 15000mg / L-20000mg / L, and the sludge reflux is set in the reactor pump to return the mud-water mixture in the reactor to the facultative tank, and the return ratio is 200%. And use hollow fiber membrane modules for mud-water separation.

Embodiment 3

[0018] The wastewater to be treated is vitamin wastewater, the hydraulic retention time of the facultative pool is 16 hours, the hydraulic retention time of the membrane bioreactor is 10 hours, the sludge concentration of the biochemical system is controlled at 15000-20000mg / L, and the sludge return pump is installed in the reactor. The mud-water mixture in the reactor is returned to the facultative tank, and the return ratio is 200%. And use hollow fiber membrane modules for mud-water separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com