Plasma air purification method for sterilizers

A plasma and air purification technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as filter failure, filter element deformation, and increased costs, and achieve easy separation and cleaning, and air return The effect of high efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

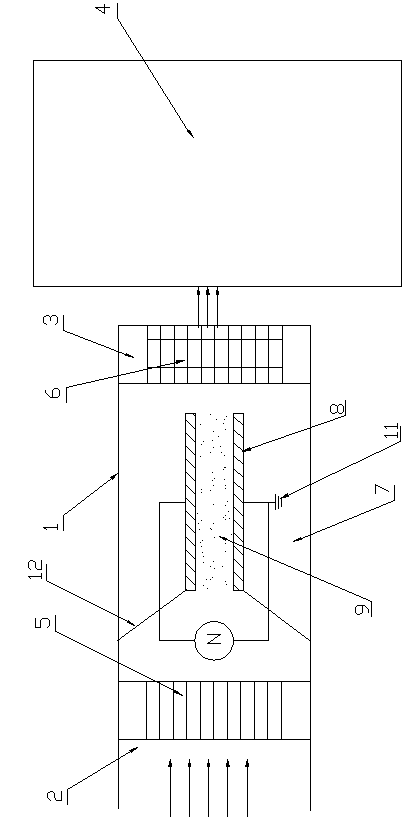

[0010] refer to figure 1 , a plasma air purification method suitable for sterilizers, comprising a housing 1, one side of the housing 1 is provided with an air inlet 2, and the other side is provided with an air outlet 3, and the air outlet 3 is connected with the sterilization chamber 4 connected, an electrostatic precipitator filter 5 is provided at the air inlet 2, an adsorption device 6 with a filter hole is provided at the air outlet 3, and in the housing 1 between the air inlet 2 and the air outlet 3 A plasma generation chamber 7 is provided, and a plasma generation device is installed in the chamber 7. The plasma generation device includes at least two comb-shaped electrode plates 8 arranged in parallel, and a discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com