Ceramic wastewater treatment method and device

A wastewater treatment and wastewater technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of insufficient attention to environmental protection, limited on-site space expansion of treatment structures, and inability to meet discharge and reuse requirements for wastewater, and achieve reliable Purifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

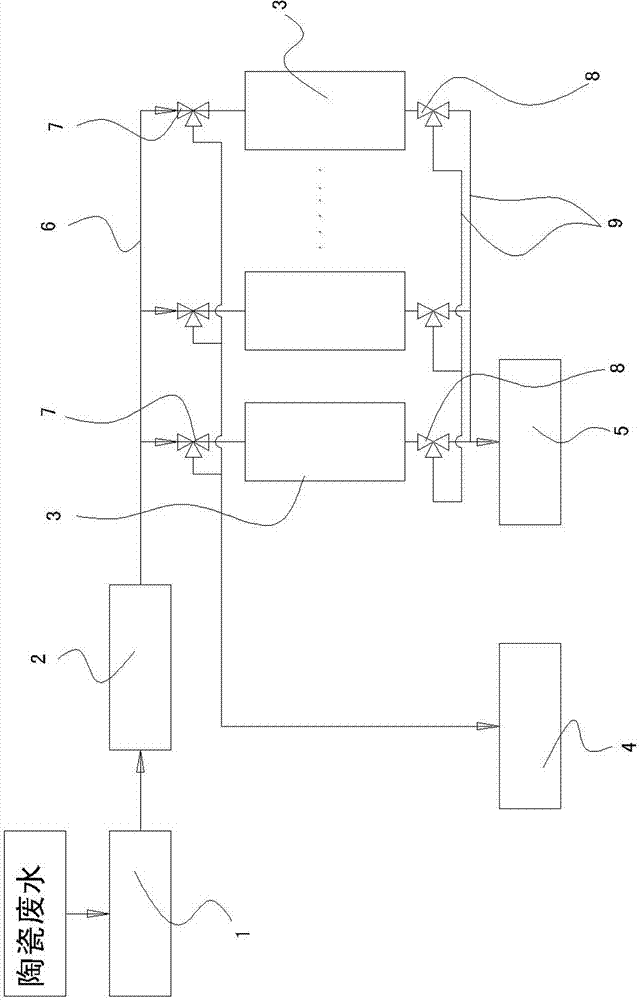

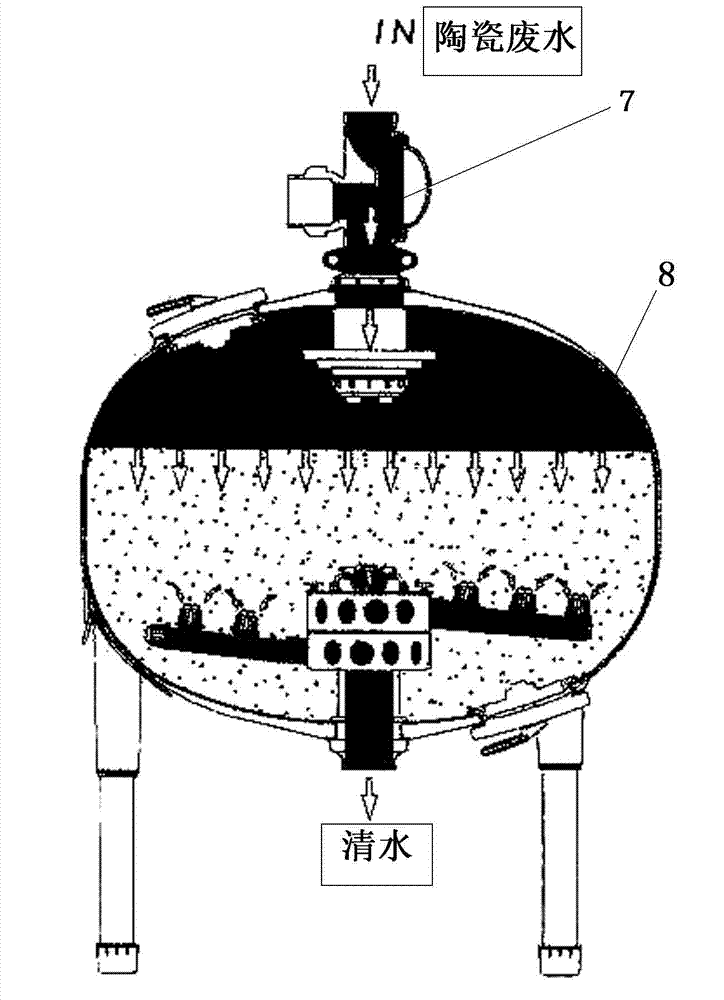

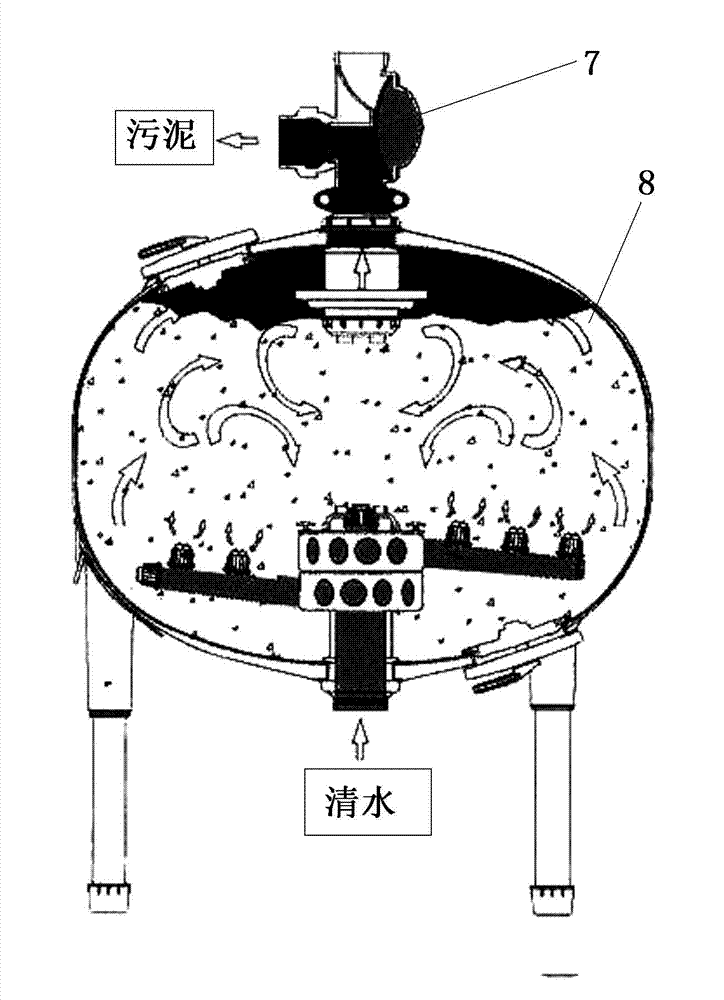

[0016] Such as figure 1 As shown, the ceramic wastewater treatment device of the present invention is realized in this way, including a wastewater settling tank 1, a wastewater pump 2, more than two sets of high-efficiency precision processors 3, a sludge tank 4, a clear water tank 5, and the wastewater settling tank 1 passes through the waste water Pump 2, water pipe 6, one of the valve ports of the waste water three-way valve 7 connected to the waste water inlet of more than two sets of high-efficiency precision processors 3, connected to the waste water inlets of more than two sets of high-efficiency precision processors 3, more than two sets of The clean water outlet with three-way valve 8 of the high-efficiency precision processor 3 is connected to the clean water pool 5 through one of the valve ports of the three-way valve 8 and the pipeline 9, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com