Sinter return fine adjustment method and system

A technology of sintering return and adjustment method, which is applied in the field of iron and steel smelting, can solve the problems of returning ore shortage, return ore overflow, and low degree of refinement, and achieve the effect of uniform use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

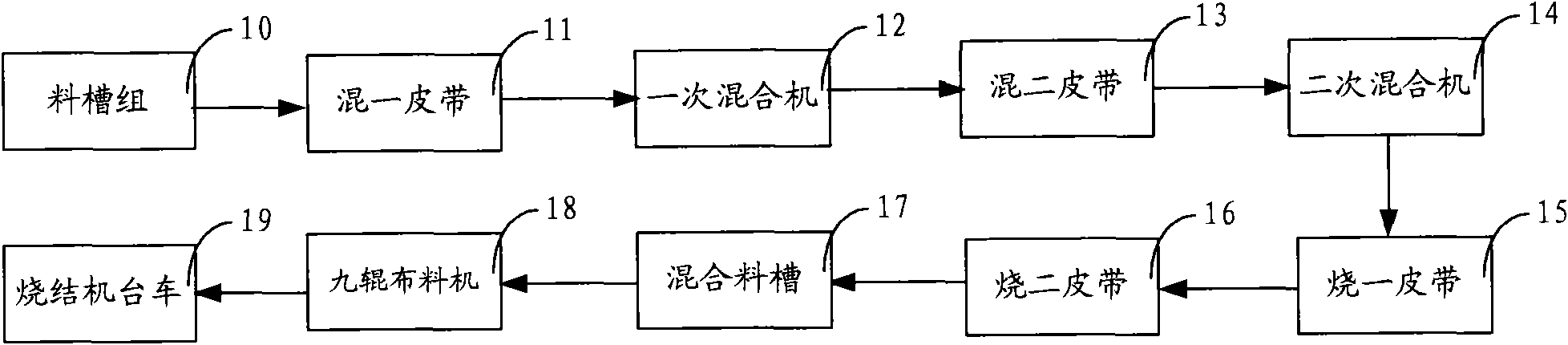

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

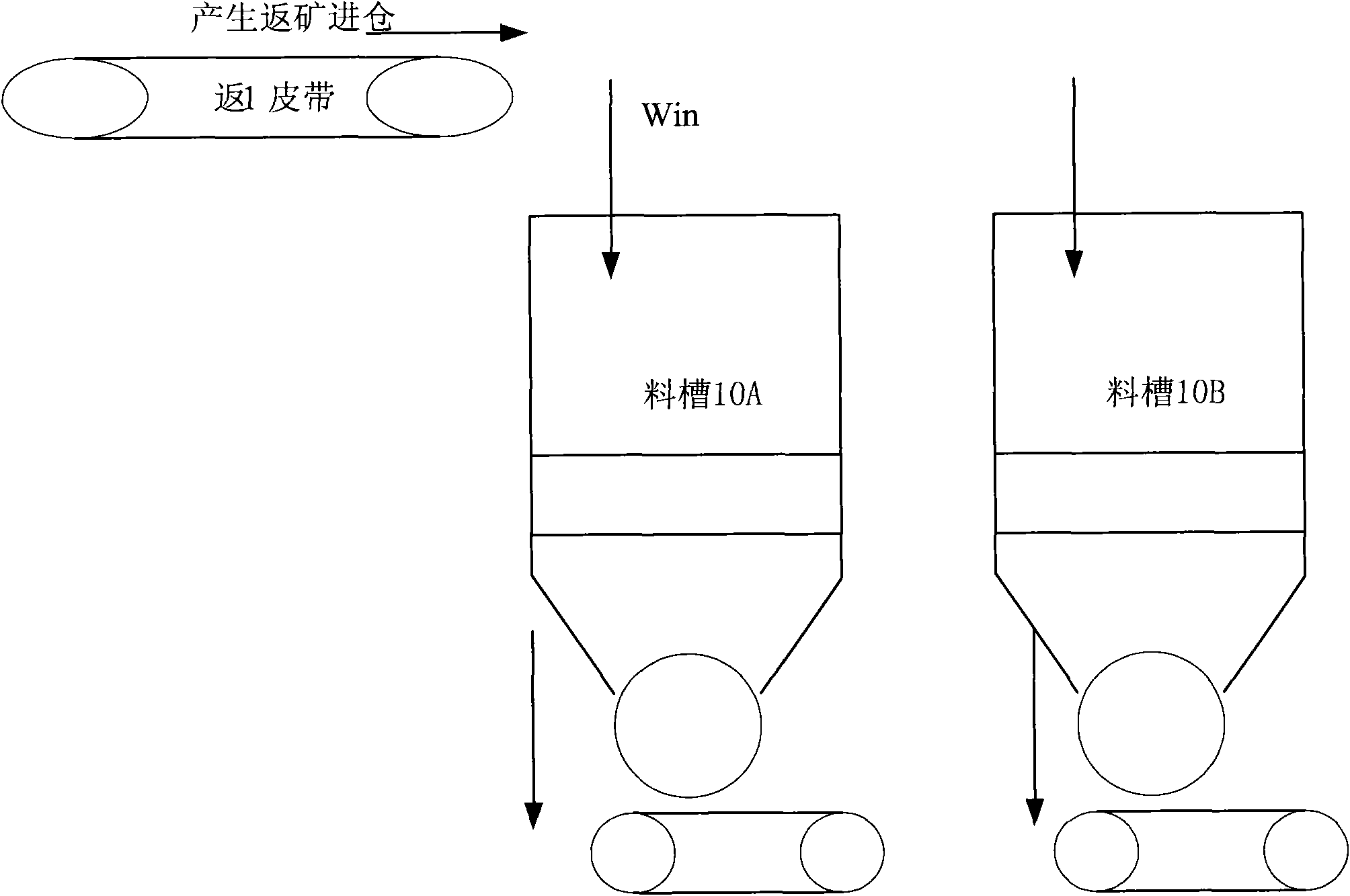

[0022] The present invention considers the material level of the two return ore troughs, and then combines the change of the material level of the return ore trough to formulate the return ore adjustment strategy and the return ore adjustment amount, so as to realize the fine adjustment of the return ore and meet the uniform use Return requirements.

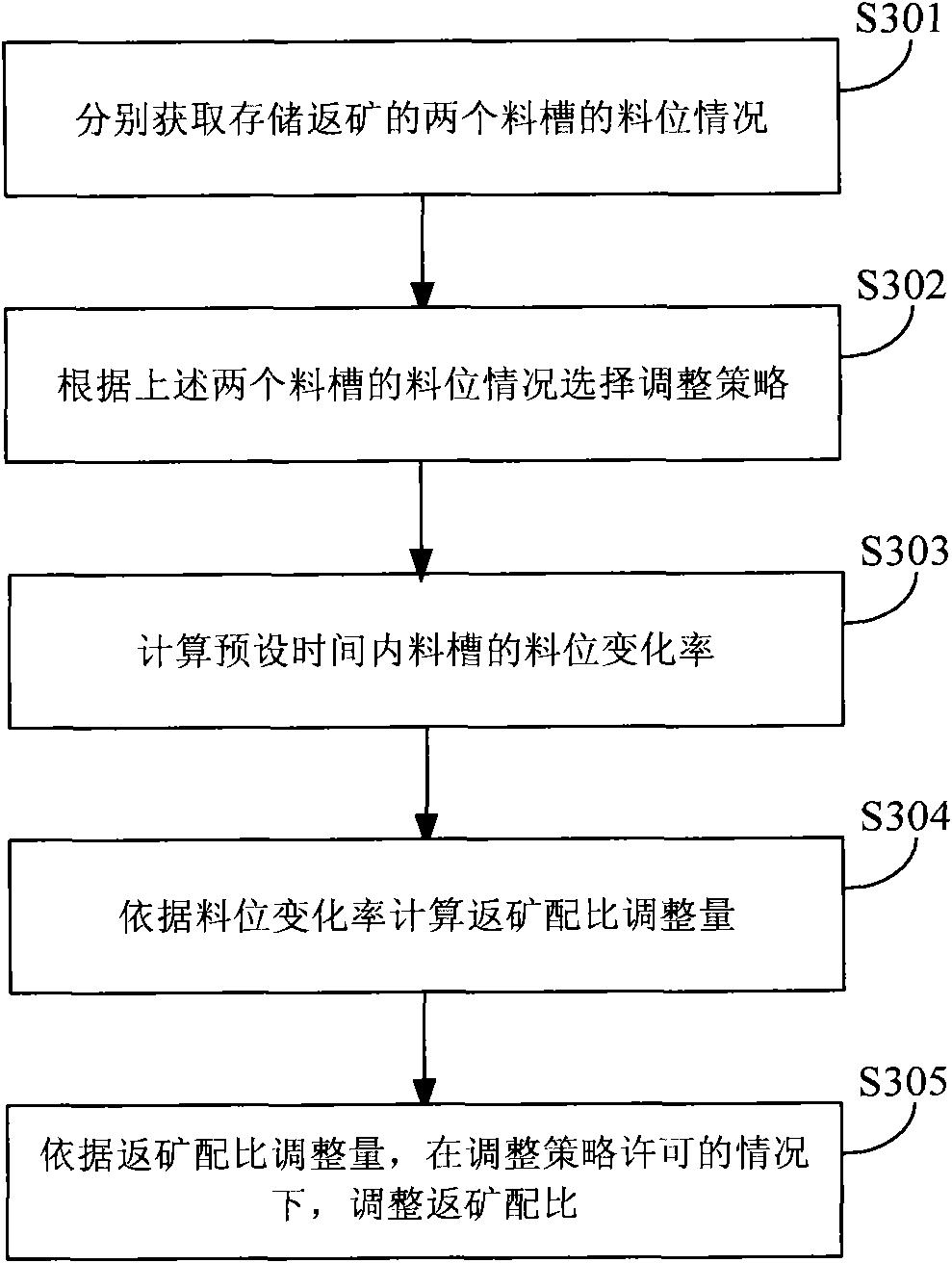

[0023] see image 3 , shows the sintering return ore adjustment method of the present invention, which specifically includes the following steps.

[0024] Step S301, obtain the material levels of the two troughs for storing the returned ore respectively. According to the height of the returning ore material level in the trough, the present invention is subdivided into first-level m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com