Method for optimizing controlling denitrification and phosphorus release in double precipitation pool by A*/O technique

An optimized control, secondary sedimentation tank technology, applied in aerobic and anaerobic process treatment, etc., can solve problems such as low compliance rate and unstable treatment effect of single-sludge biological nitrogen and phosphorus removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

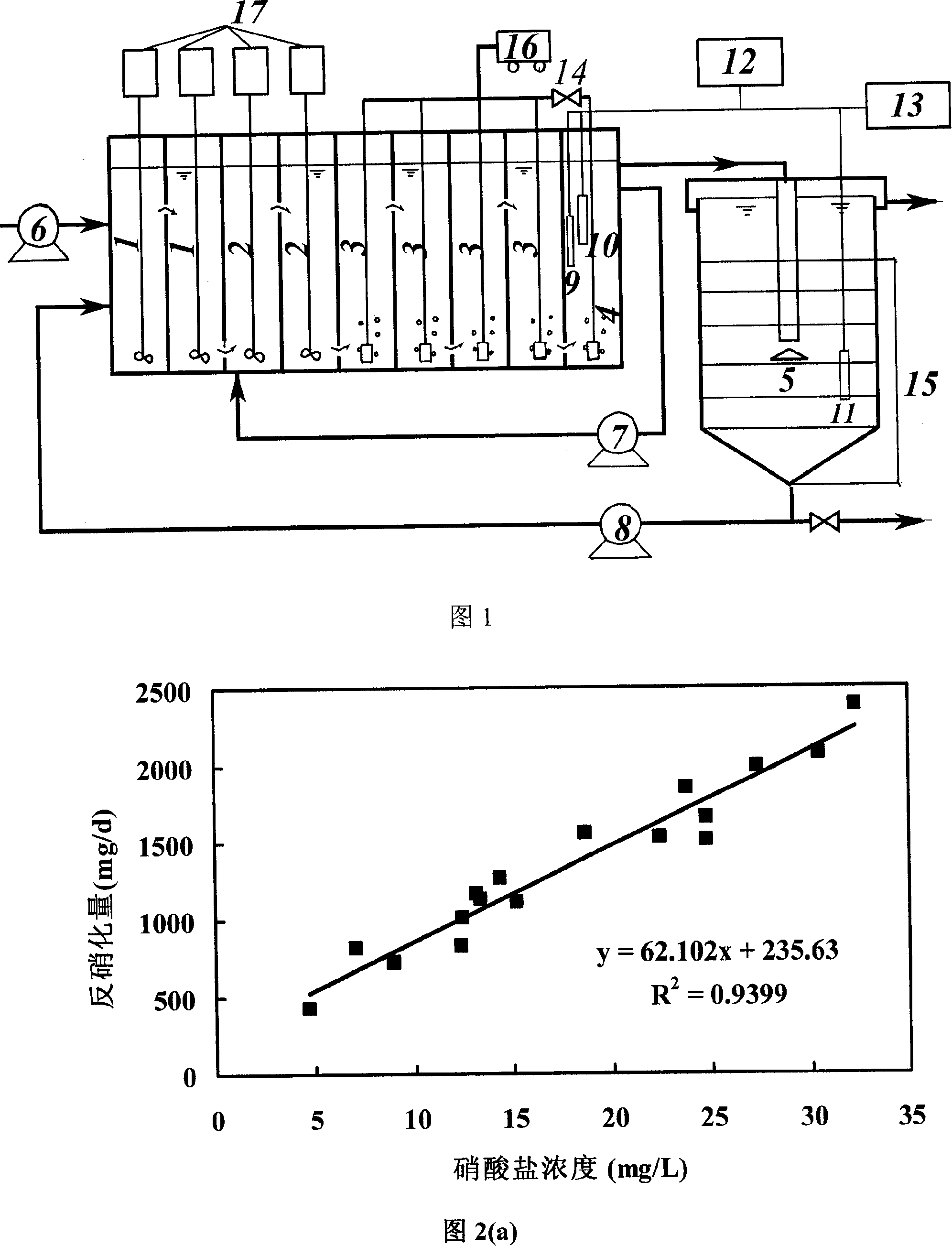

Method used

Image

Examples

Embodiment Construction

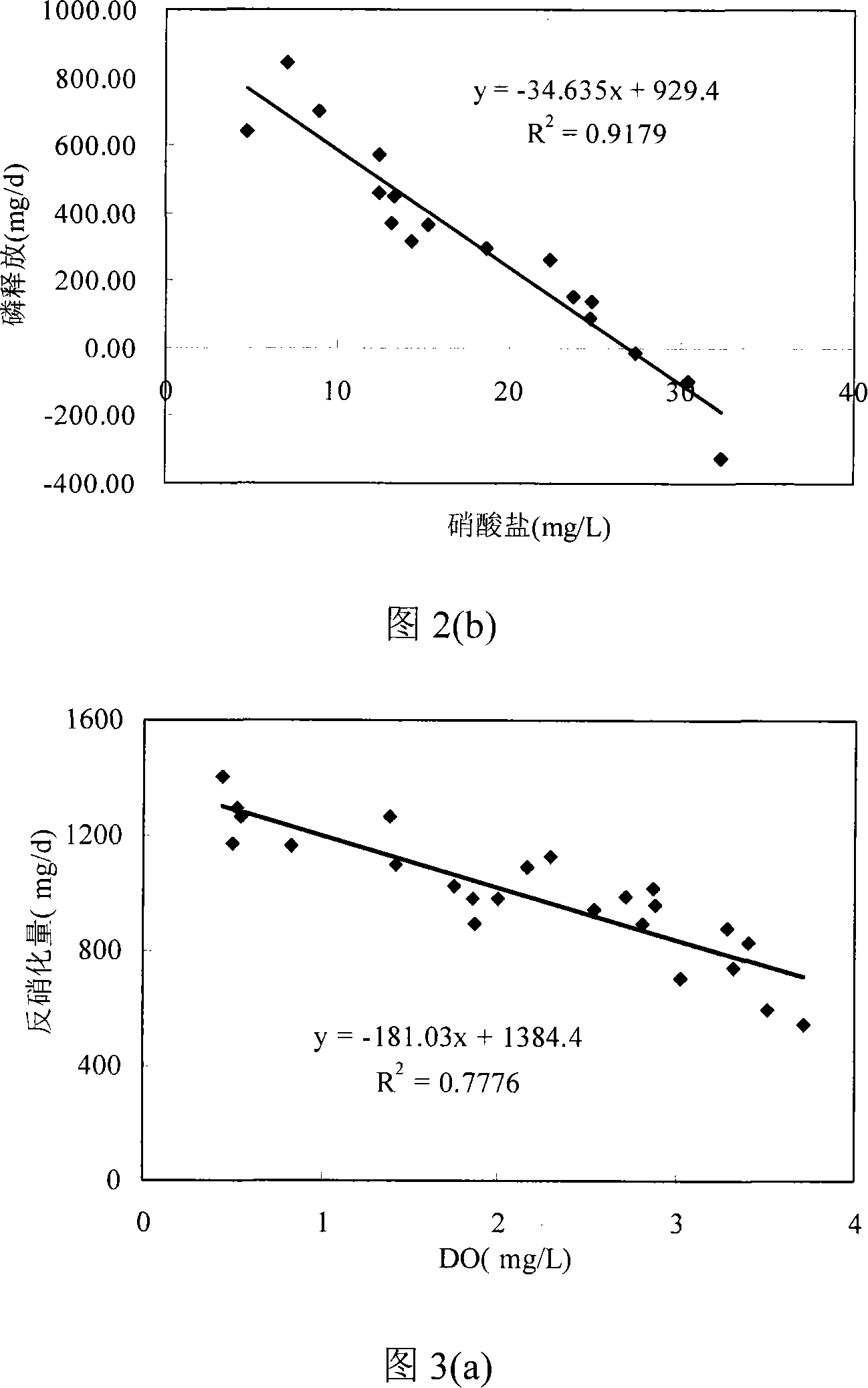

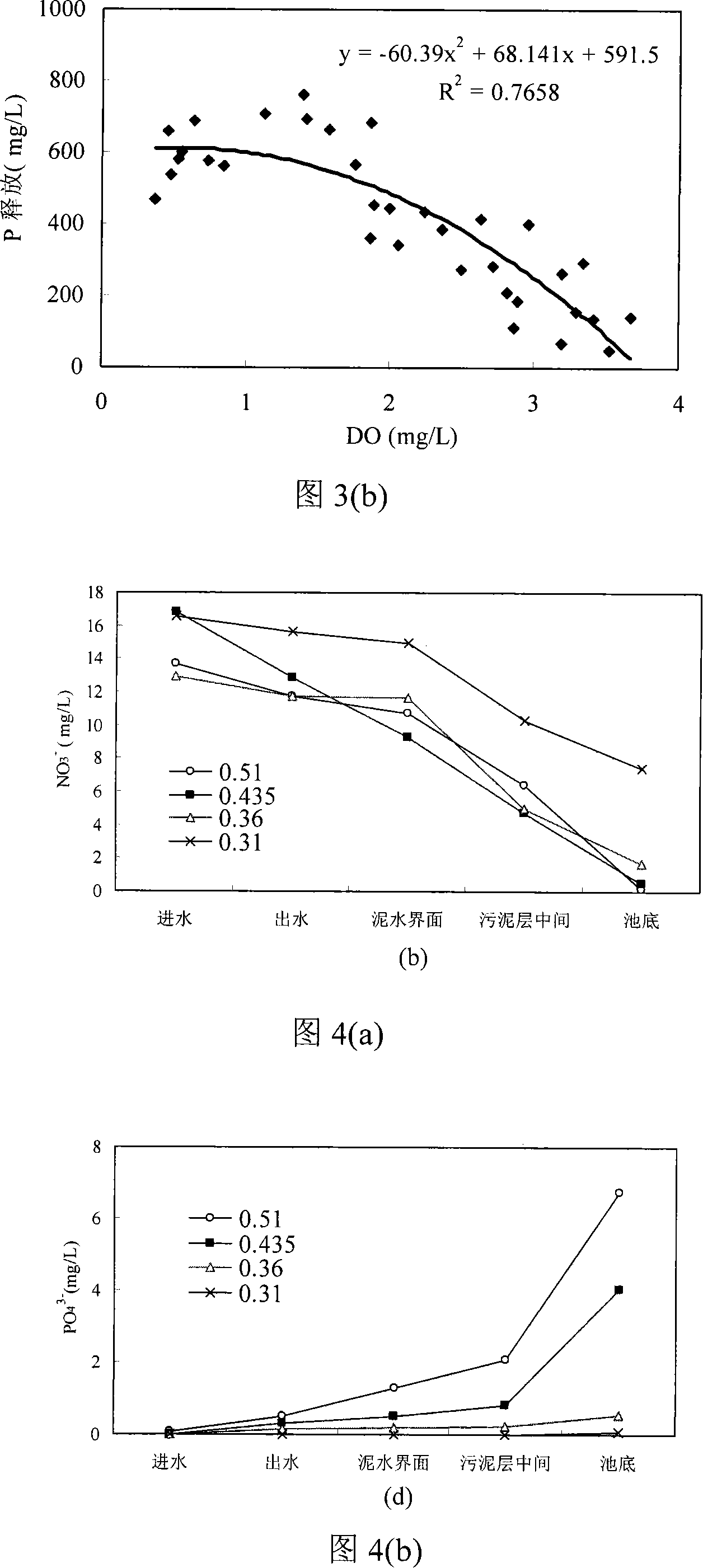

[0016] 1 During the test, synthetic beer wastewater (COD=251-406mg / L, total nitrogen TN=41-78mg / L and total phosphorus TP=7.1-11.5mg / L) was used, the hydraulic retention time was 9h, and the sludge age was 10- On 12 days, the sludge concentration is 3500±100mg / L, the pH of the influent is controlled at 7.2-7.6, and the temperature is controlled at 20-23°C by the heating rod. When the DO concentration of the secondary sedimentation tank is 0.66mg / L, when the sludge bed When the height is higher than 2 / 3 of the effective height of the secondary settling tank, when the nitrate concentration is 13mg / L, the nitrate concentration in the return sludge is always less than 2mg / L. The correlation coefficient between the concentration of nitrate at the end of the area and the degree of denitrification in the secondary sedimentation tank is 0.9399. There is a negative correlation between the concentration of nitrate in the effluent of the aerobic zone and the release of phosphorus, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com