Cold air surrounding type hot air decentralized heating device

A heating device, wrap-around technology, applied in the direction of hot air central heating system, household heating, heating methods, etc., can solve the problems of difficult to meet the temperature requirements in the working area, difficult to arrange heating methods, vertical temperature stratification, etc., to eliminate Effect of heat stratification, reduction of heat stratification, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

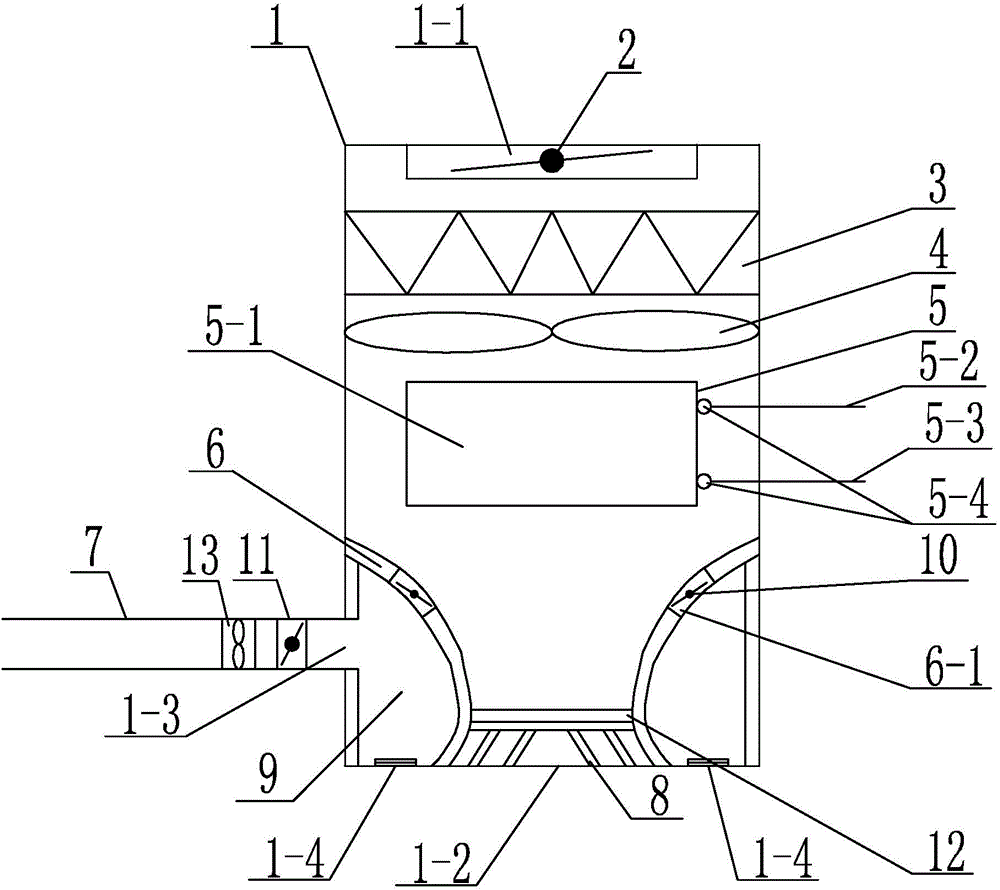

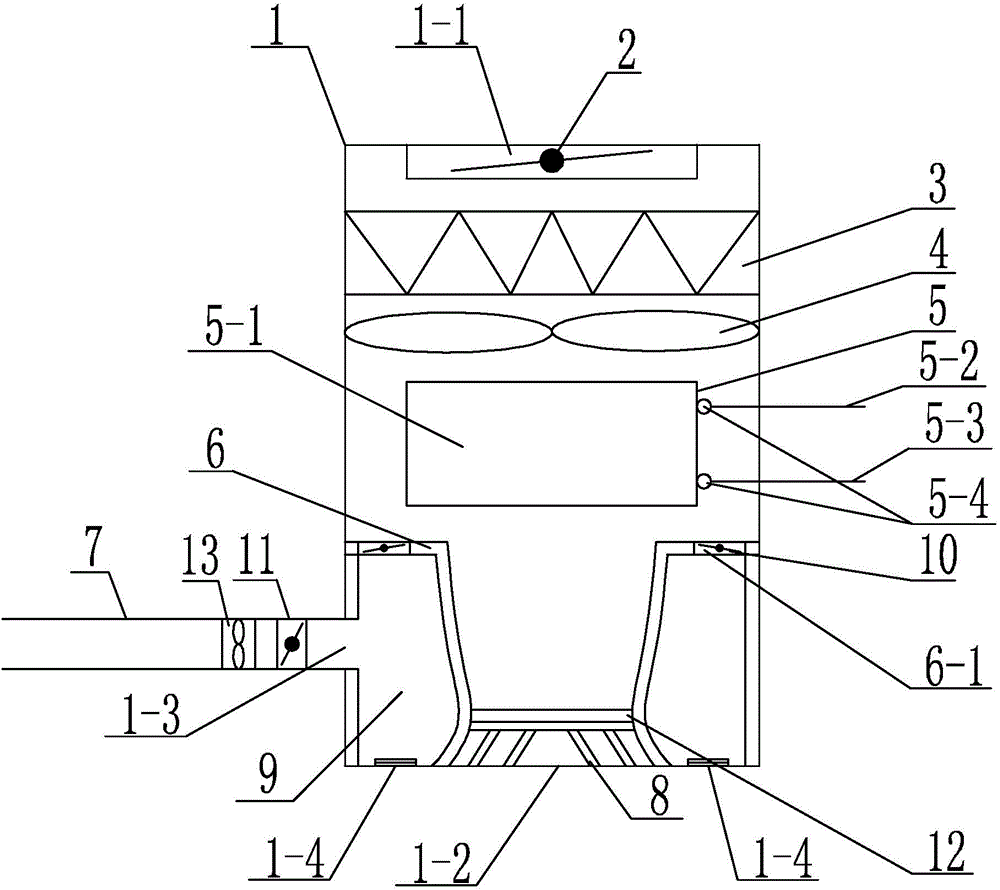

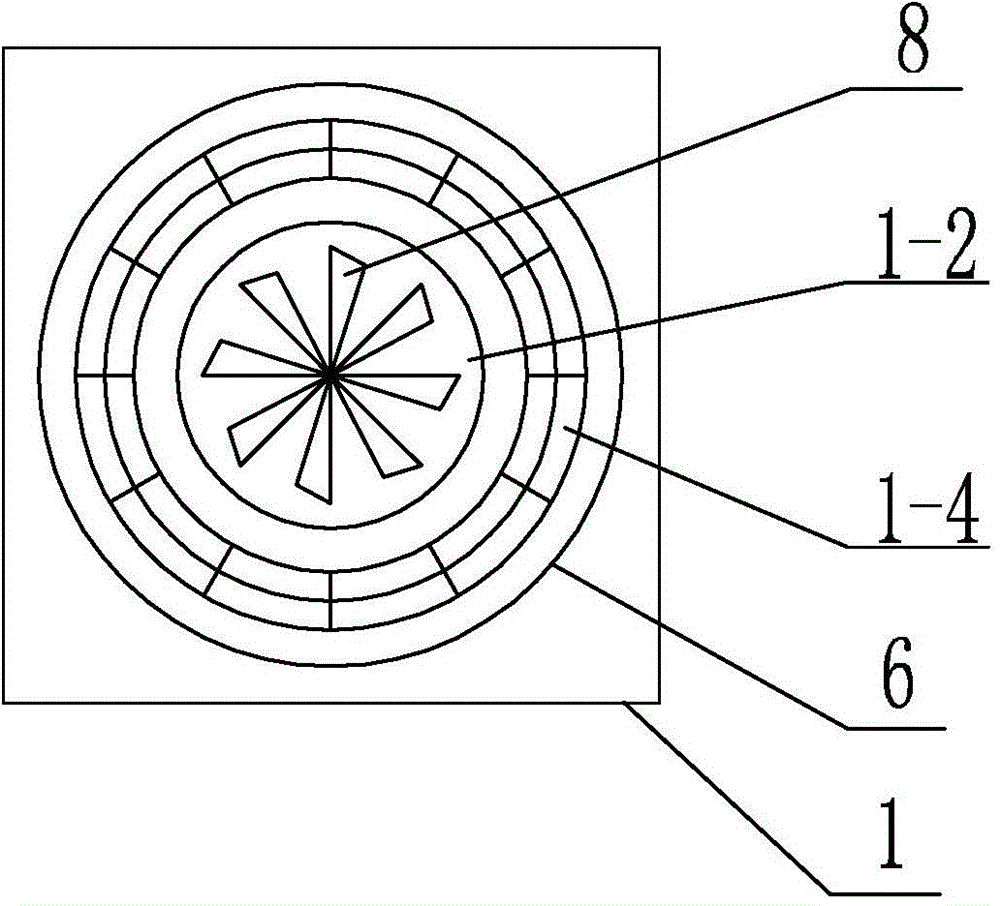

[0014] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, the cold wind surrounding hot air dispersion heating device described in this embodiment includes a housing 1, a filter 3, a return air fan 4, a heat exchanger assembly 5, a partition cylinder 6, a fresh air duct 7, a fresh air Fan 13, at least one return air bypass valve 10 and a plurality of air outlet deflectors 8, the top surface of the housing 1 is processed with a first air inlet 1-1, and the bottom surface of the housing 1 is processed with a first air outlet The tuyere 1-2, the inside of the housing 1 is provided with a filter 3, a return air fan 4 and a heat exchanger assembly 5 sequentially from top to bottom, and the separation cylinder 6 is vertically arranged below the heat exchanger assembly 5 , the area of the top cross-section of the partition cylinder 6 is greater than the area of the bottom cross-section of the partition cylinder 6, ...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 Describe this embodiment, the heat exchanger assembly 5 in this embodiment includes a heat exchanger body 5-1, a heat exchanger water supply pipe 5-2, a heat exchanger return water pipe 5-3 and two flexible joints 5- 4. The heat exchanger body 5-1 communicates with the heat exchanger water supply pipe 5-2 through one of the two flexible joints 5-4, and the heat exchanger body 5-1 communicates with the heat exchanger water supply pipe 5-2 through two Another soft joint 5-4 in the soft joint 5-4 communicates with the heat exchanger return water pipe 5-3. Components not mentioned in this embodiment are the same in structure and connection relationship as in Embodiment 1.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 2 Describe this embodiment, the cold wind surround type hot air dispersion heating device described in this embodiment also includes a return air valve 2 and a fresh air valve 11, the return air valve 2 is arranged at the first air inlet of the casing 1 1-1, the fresh air damper 11 is set in the fresh air duct 7 and close to the second air inlet 1-3. The purpose of return air damper 2 and fresh air damper 11 setting is to adjust the flow size of indoor return air and cold wind respectively. Components not mentioned in this embodiment are the same in structure and connection relationship as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com