Method for treating waste secondary battery

A secondary battery and treatment method technology, applied in battery recycling, waste collector recycling, recycling technology, etc., can solve problems such as potential safety hazards, difficulty in crushing, low recovery rate of valuable elements, etc., to prevent explosions and prolong stay the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

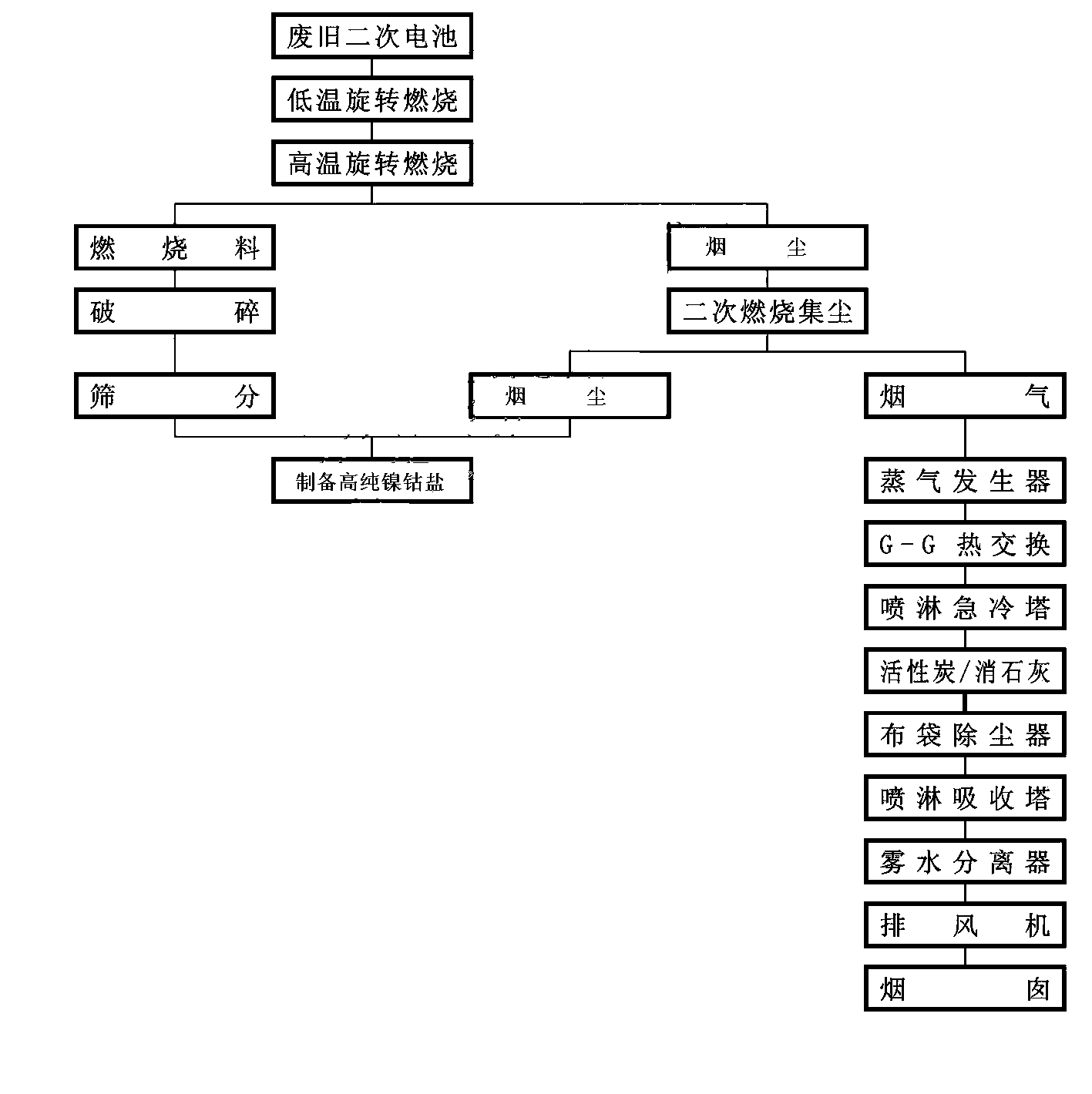

[0030] A kind of processing method of waste nickel-metal hydride battery, such as figure 1 As shown, it specifically includes the following steps:

[0031] 1) Put the waste Ni-MH battery into the tank filled with electrolyte, so that the residual power in the waste Ni-MH battery is fully discharged;

[0032] 2) Use a conveyor to evenly send the discharged waste Ni-MH batteries into the combustion chamber of the rotary kiln;

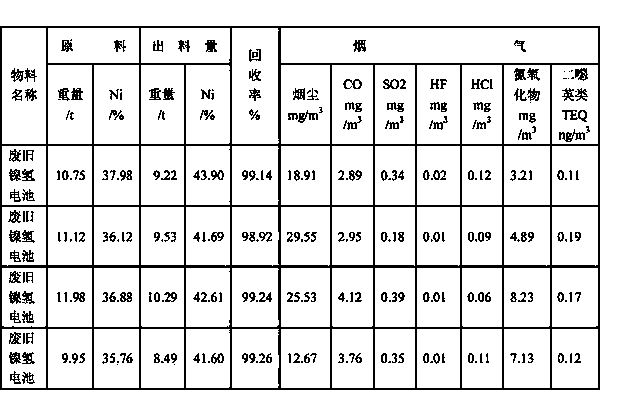

[0033]3) Ignition in the rotary kiln for roasting, the combustion flame is introduced into the furnace body through a tangential direction along the combustion chamber furnace body of the rotary kiln, the waste nickel-hydrogen battery and the high-temperature combustion gas are violently stirred, and the oxidation reaction occurs rapidly, and the combustion flame is 2 Rotate along the furnace body at a speed of ~3 m / s, and move axially along the furnace body at a speed of 2~3 m / s to maintain the primary combustion temperature of the rotary kiln within 10...

Embodiment 2

[0046] A kind of processing method of waste lithium ion battery, such as figure 1 As shown, it specifically includes the following steps:

[0047] 1) Put the waste lithium-ion battery into a tank filled with electrolyte, so that the residual power in the waste lithium-ion battery is fully discharged;

[0048] 2) Use a conveyor to evenly send the discharged waste lithium-ion batteries into the rotary kiln combustion chamber;

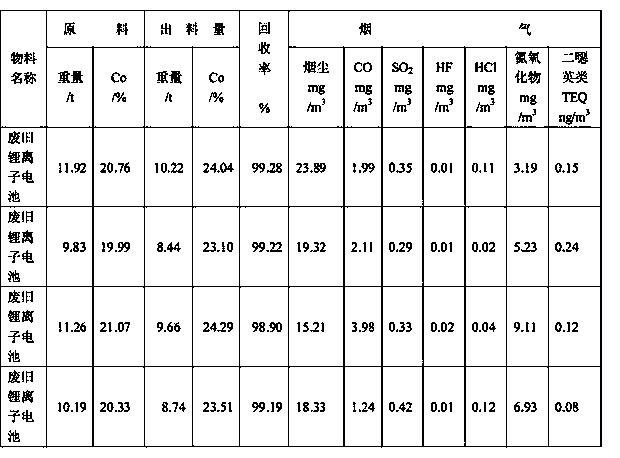

[0049] 3) The rotary kiln is ignited for incineration. The combustion flame is introduced into the furnace body through a tangential direction along the combustion chamber of the rotary kiln. The waste lithium-ion battery and the high-temperature combustion gas are violently stirred, and the oxidation reaction occurs rapidly. The combustion flame is 2 Rotate along the furnace body at a speed of ~3 m / s, and move axially along the furnace body at a speed of 2~3 m / s to maintain the primary combustion temperature of the rotary kiln within 130-150 °C, and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com