Light flame-retardant phenolic foam material and preparation method thereof

A phenolic foam material, lightweight technology, applied in the field of thermal insulation materials, can solve the problems of poor fire resistance, impact resistance and damage resistance, etc., to increase residual weight and strength, enhance flame retardancy and fire resistance, closed cells high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

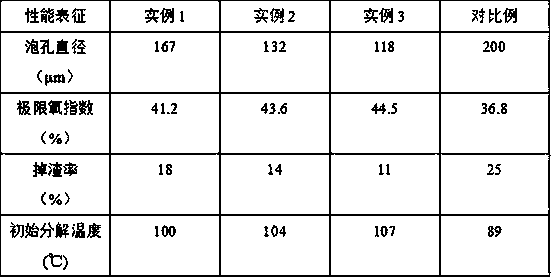

Examples

example 1

[0025] Take 20g of diatomaceous earth and 2g of multi-walled carbon nanotubes, add them into 200mL of deionized water, and disperse them with 200W ultrasonic wave at 60°C for 20min, then heat to 90°C, keep the reaction for 20h, cool to room temperature, filter, and use deionized Wash the filter residue twice with water, then place the filter residue in a drying oven, and dry at 70°C for 10 hours to obtain modified diatomite. Take 90g of 10% phenol solution at 70°C, mix it with 10g of linseed oil, and heat it at 300r / min insulated and stirred for 10 minutes, then dropwise added 20% hydrochloric acid to adjust the pH to 3, and continued to stir for 20 minutes to obtain a prepolymer, which was added to 54 g of 10% formaldehyde solution with a mass fraction of 20% Adjust the pH to 9 with sodium hydroxide solution, heat to 60°C, and keep it warm for 30 minutes, then add 4.5g of titanium diboride, heat it to 90°C, keep it warm for 50 minutes, and then adjust the pH to neutral with 2...

example 2

[0027] Take 25g of diatomite and 2g of multi-walled carbon nanotubes, add them into 250mL of deionized water, and disperse them with 200W ultrasonic wave at 70°C5 for 25min, then heat to 95°C, keep the reaction for 22h, cool to room temperature, filter, and use Wash the filter residue twice with ion water, then place the filter residue in a drying oven, and dry at 75°C for 11 hours to obtain modified diatomite. Take 114g of 10% phenol solution at 75°C and mix it with 15g of linseed oil to Stir at 350r / min for 12min, then add dropwise 20% hydrochloric acid to adjust the pH to 4, continue stirring for 25min to obtain a prepolymer, add 63g of the prepolymer to a 10% formaldehyde solution, and use a mass fraction of 20% % sodium hydroxide solution to adjust the pH to 9.5, heat to 65°C, keep it warm for 35 minutes, then add 6.5g of titanium diboride, heat it to 92°C, keep it warm for 55 minutes, then adjust the pH to neutral with 20% hydrochloric acid , to obtain modified phenolic ...

example 3

[0029]Take 30g of diatomaceous earth and 3g of multi-walled carbon nanotubes, add them into 300mL of deionized water, and disperse them with 200W ultrasonic wave at 80°C for 30min, then heat to 100°C, keep the reaction for 24h, cool to room temperature, filter, and use deionized Wash the filter residue with water for 3 times, then place the filter residue in a drying oven, and dry it at 80°C for 12 hours to obtain modified diatomite. Take 135g of a 10% phenol solution at 80°C, mix it with 20g of linseed oil, and mix it with 400r / min insulated and stirred for 15 minutes, then dropwise added 20% hydrochloric acid to adjust the pH to 5, and continued to stir for 30 minutes to obtain a prepolymer. Add 81 g of the prepolymer to a 10% formaldehyde solution, and use a mass fraction of 20% Adjust the pH to 10 with sodium hydroxide solution, heat to 70°C, and keep it warm for 40 minutes, then add 9.0g of titanium diboride, heat it to 95°C, keep it warm for 60 minutes, then adjust the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com