Method of hydrocarbon pyrolysis and device for implementing same

A technology of pyrolysis and raw materials, which is applied in the treatment of hydrocarbon oil, hydrocarbon oil treatment products, non-catalytic thermal cracking, etc., and can solve the problems of coke formation, high capital cost of pyrolysis furnace construction, and volume reduction of coke solid carbon particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

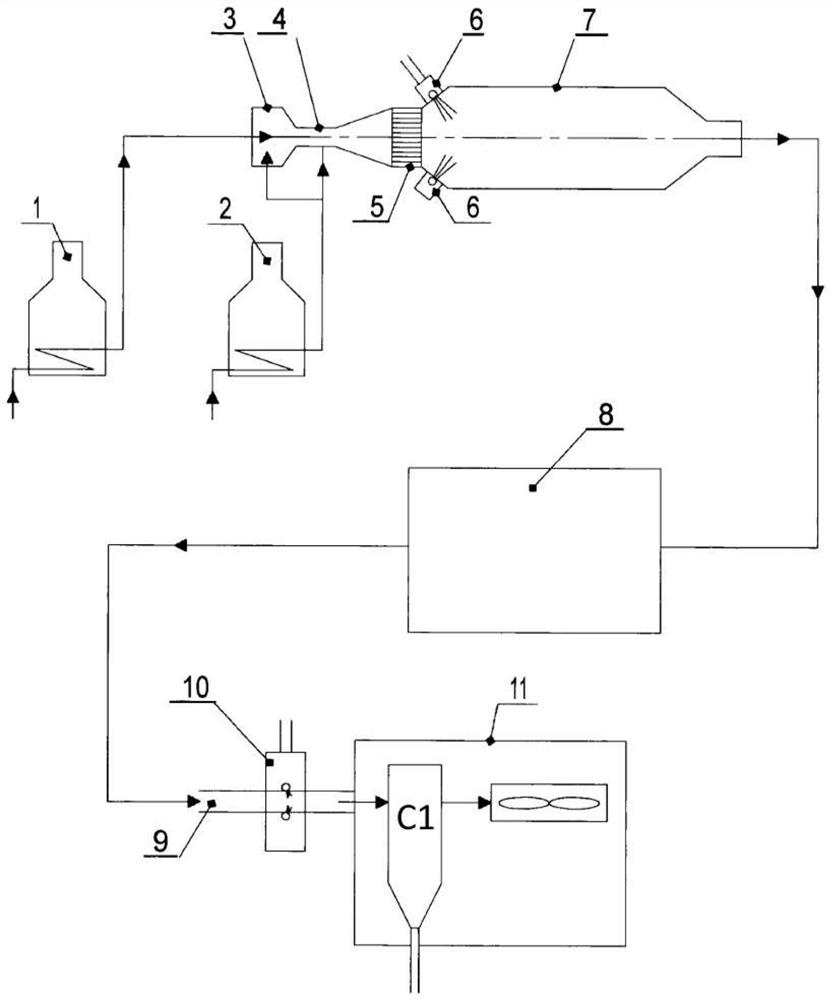

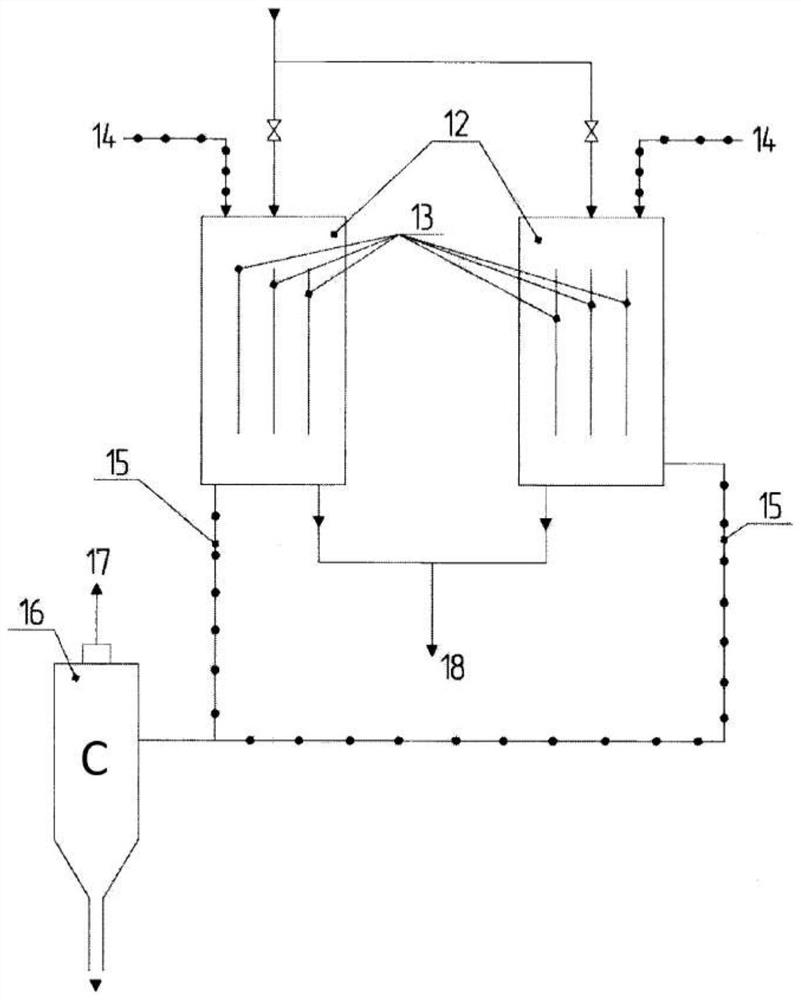

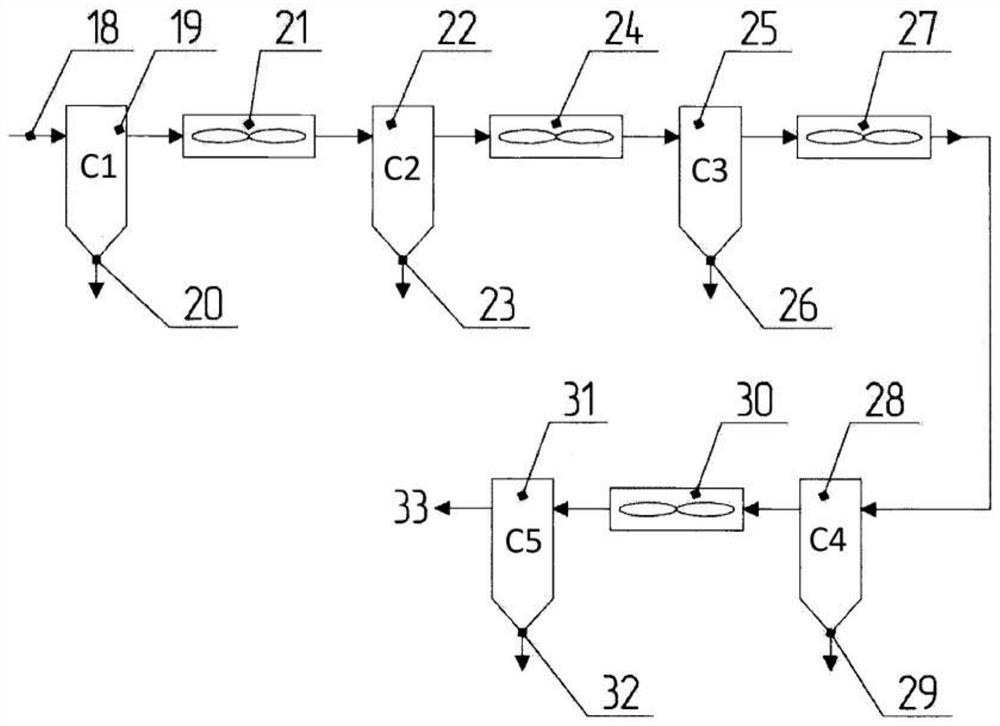

[0059] The proposed oxidative pyrolysis process of hydrocarbon feedstock was implemented in an oxidative pyrolysis pilot plant for processing 68 kg per hour of straight-run gasoline (boiling point IBP - 180 °C). The feedstock was heated to 500°C.

[0060] A mixture of 11% of the feedstock consumption of oxygen heated to 300°C and 8% of the feedstock consumption of steam heated to 100°C was used as the oxidizing agent. The shape of the fire-stop grille channel is square, with a side length of 8 mm and a wall thickness of 3 mm. The outflow rate of combustion products is 50 m / s, the oxidative pyrolysis reaction time is 0.003 seconds, and the length of the grid channel is 150 mm. There are 16 square grid channels in total, with 4 channels on each side of the grid.

[0061] The calculated adiabatic temperature of the reaction product is about 1100°C, and the actual temperature considering heat loss is about 950°C. Fuel oil is used as the quenching liquid. According to the calcu...

Embodiment 2

[0070] Modular combined oxidation pyrolysis device, processing 77 kg of normal pressure gas oil (boiling point 180-330 ℃) per hour. The feedstock was heated to 500°C.

[0071]A mixture of oxygen (heated to 300° C.) in an amount of 11% of the feedstock consumption and steam (heated to 100° C.) in an amount of 8% of the feedstock consumption was used as oxidizing agent. The shape of the channel of the fire-stop grid is square, with a side length of 8 mm and a wall thickness of 3 mm. The calculated flow velocity of the combustion products is 60 m / s, the oxidation pyrolysis reaction rate is 0.003 seconds, and the length of the grid channel is 150 mm. There are 16 square grate channels in total, 4 channels on each side of the grate. The calculated adiabatic temperature of the reaction product was about 1240°C, and the actual temperature considering heat loss was about 980°C. Fuel oil is used as the quenching liquid. According to the calculation, 2.0 kg of fuel oil is taken for e...

Embodiment 3

[0081] At the combined oxidative pyrolysis unit of the same model, oxidative pyrolysis of methane gas to produce hydrogen is carried out. The consumption of ethane was 19 kg / h. Heating ethane to 500°C

[0082] A mixture of 10% of the raw material consumption of oxygen (heated to 300°C) and 10% of the raw material consumption of steam (heated to 100°C) was used as the oxidizing agent. The shape of the channel of the fire-stop grid is square, the side length is 8 mm, the wall thickness is 3 mm, the calculated flow velocity of the combustion product is 60 m / s, the oxidation pyrolysis reaction rate is 0.003 seconds, and the length of the grid channel is 150 mm. There are 4 square grate channels, 2 channels on each side of the grate. The calculated adiabatic temperature of the reaction product is about 1200°C (real temperature is about 1050°C considering heat loss).

[0083] Fuel oil is used as the quenching liquid. According to the calculation, 2.2 kg of fuel oil is taken for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com