Method for distilling a hydrocarbon material and a plant for carrying out said method

A hydrocarbon and raw material technology, applied in the direction of hydrocarbon distillation, fractional distillation, multi-effect evaporation, etc., can solve the problems of impossible components to be divided into fractions, impossible to obtain engine fuel, infiltration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

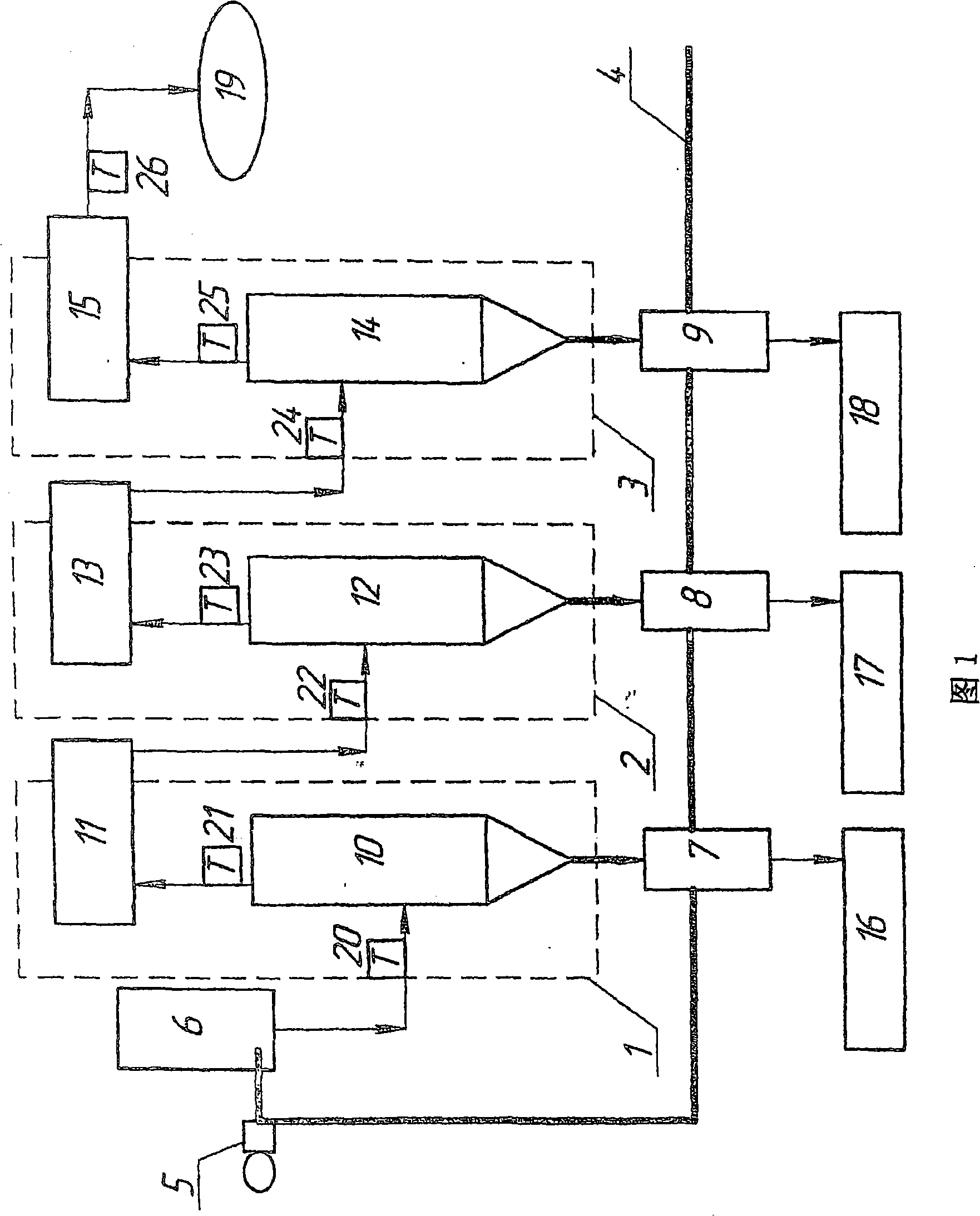

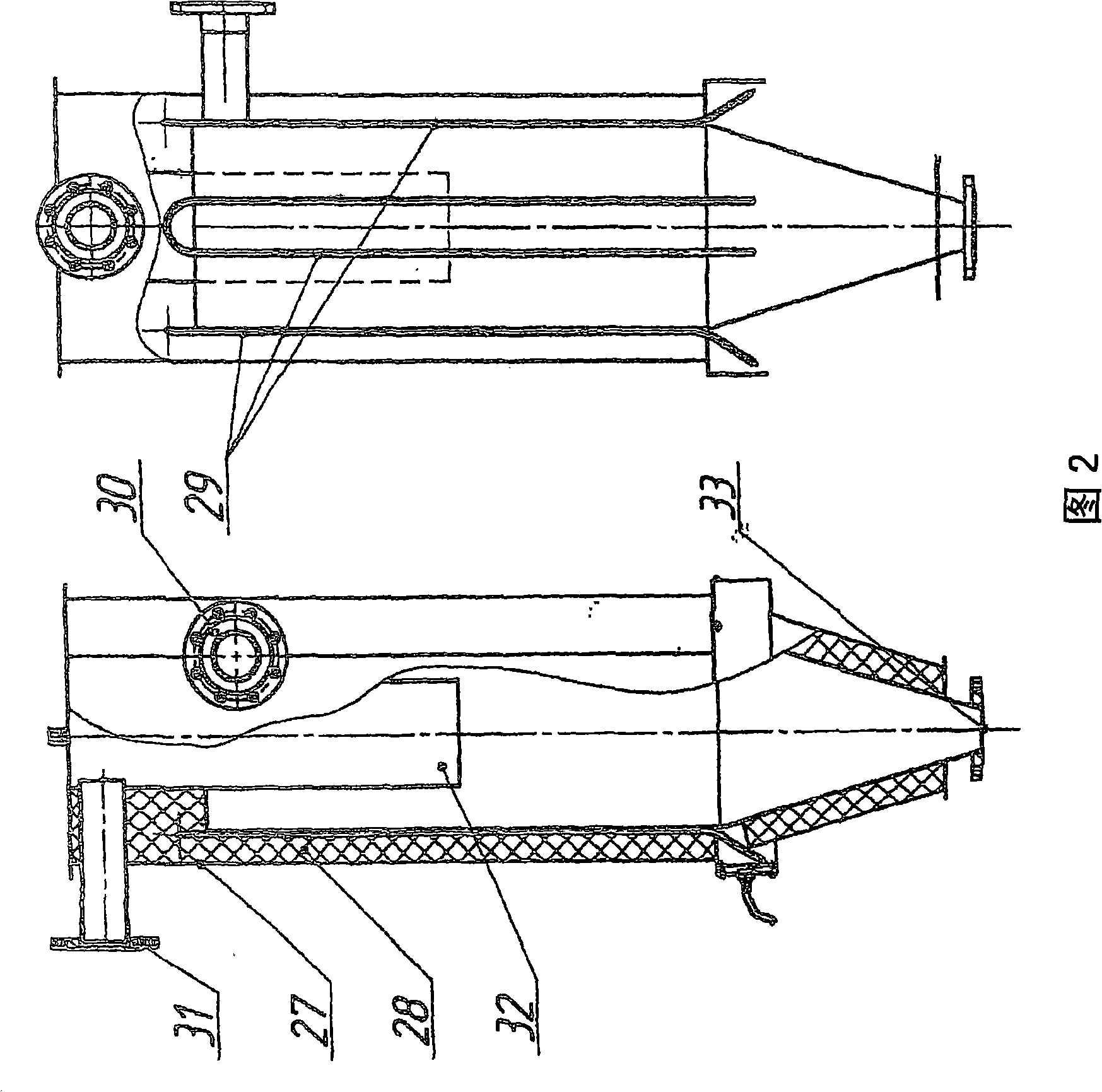

[0030] The hydrocarbon raw material distillation unit (Fig. 1) comprises: the raw material first, second and third stage distillations connected in series with pipelines, pipeline 4 for transporting raw materials, pump 5, furnace 6 for heating raw materials, which is made of pipelines and First stage distillation connection. Heat exchangers 7, 8, 9 are installed in series on the raw material delivery pipeline 4. A cyclone evaporator 10 and a cooler 11 are arranged in the first stage raw material distillation, a cyclone evaporator 12 and a cooler 13 are arranged in the second stage raw material distillation, and a cyclone evaporator 14 and a cooler 15 are arranged in the third stage raw material distillation. The cyclone evaporators 10, 12, and 14 of each stage of distillation are connected with the coolers 11, 13, and 15 with pipelines, and the heat exchangers 7, 8, and 9 are connected with the first, second, and third stages respectively. The cyclone evaporators 10, 12, 14 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com