Distiller's yeast receiving device, intelligent distiller's yeast carrying production line and distiller's yeast block carrying method

A technology of distiller's koji and koji, applied in the field of intelligent manufacturing equipment industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

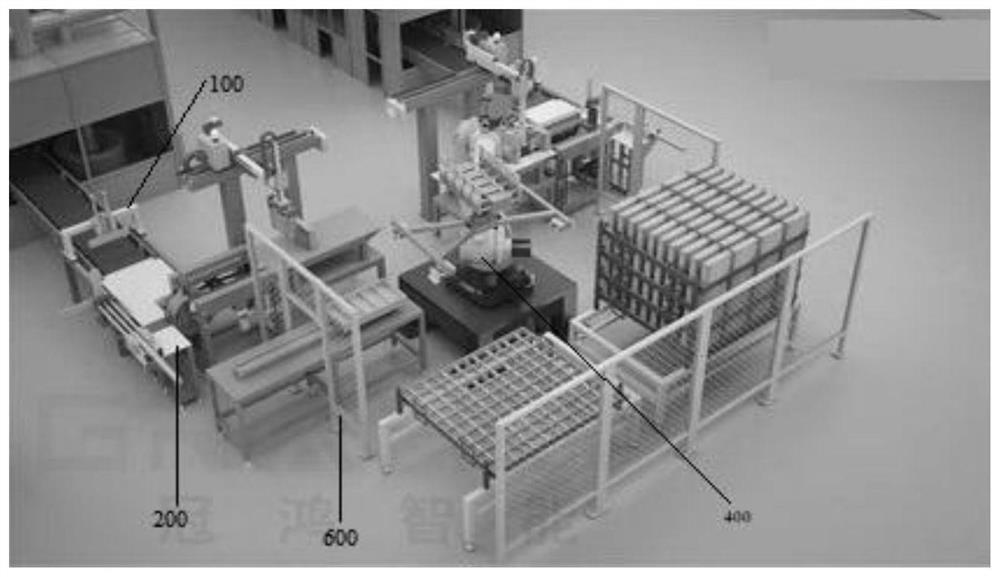

[0136] Example 1, such as figure 1 As shown, an intelligent wine koji handling production line includes: a conveyor, a koji connecting device 100, a material sorting device 200, a koji coding robot 400, a safety fence 600, and a koji stand placement area.

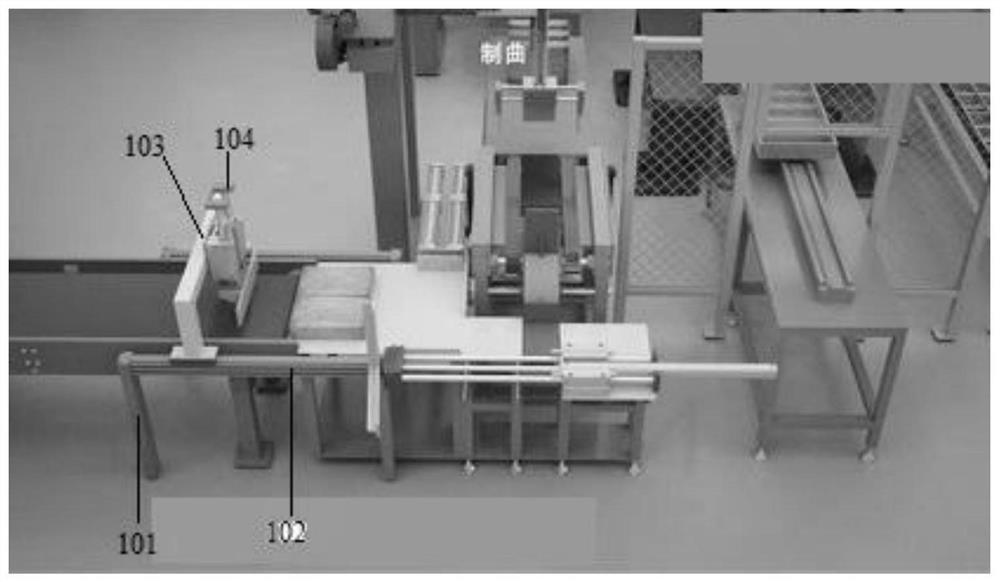

[0137] Wherein, the bending device 100 includes: a bending transverse frame 103, longitudinal track members distributed on both sides of the conveyor, a push plate lifting assembly 104, a bending platform 105, a lateral pushing member 106, and a bending block connecting member 107 , connected to the curved positioning baffle 108, a single curved block forward space platform 109, and the side baffle 110;

[0138] Described longitudinal track member comprises: column 101, longitudinal beam 102, and the longitudinal track that is arranged on the top surface of longitudinal beam 102, conveyor adopts belt conveying, and both sides of conveyor are all provided with column 101 and longitudinal beam 102 ( That is, both sides of t...

Embodiment 2

[0202]Embodiment 2, there is a problem in the first generation curved block steering-transition conveying integrated machine 201 of embodiment 1: the flip plate includes: the first plate and the second plate, the first plate is the tangential direction of the curved block steering cylinder; The second plate is the radial direction of the curved block steering cylinder; this way is the conventional practice of flipping the plate-curved block steering cylinder (the unified design of the inventor team).

[0203] However, in actual operation, what happens as Figure 14b The problem is that the turning board rotates from position A to position B to realize the turning of the curved block, but realizing the turning of the curved block does not mean that the curved block can move horizontally from the position B.

[0204] Because the central axis of rotation of the transitional conveyor belt will be close to the space table 109 for moving forward with a single curved block, the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com