A vocs exhaust gas adsorbent desorption pyrolysis furnace

A technology of pyrolysis furnace and adsorbent, which is applied in the direction of combustible gas purification, combustible gas purification/transformation, and other chemical processes, and can solve problems such as leakage, no solution for electrothermal purification filter elements, and VOCs exhaust gas sealing failure, etc., to achieve The effect of reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

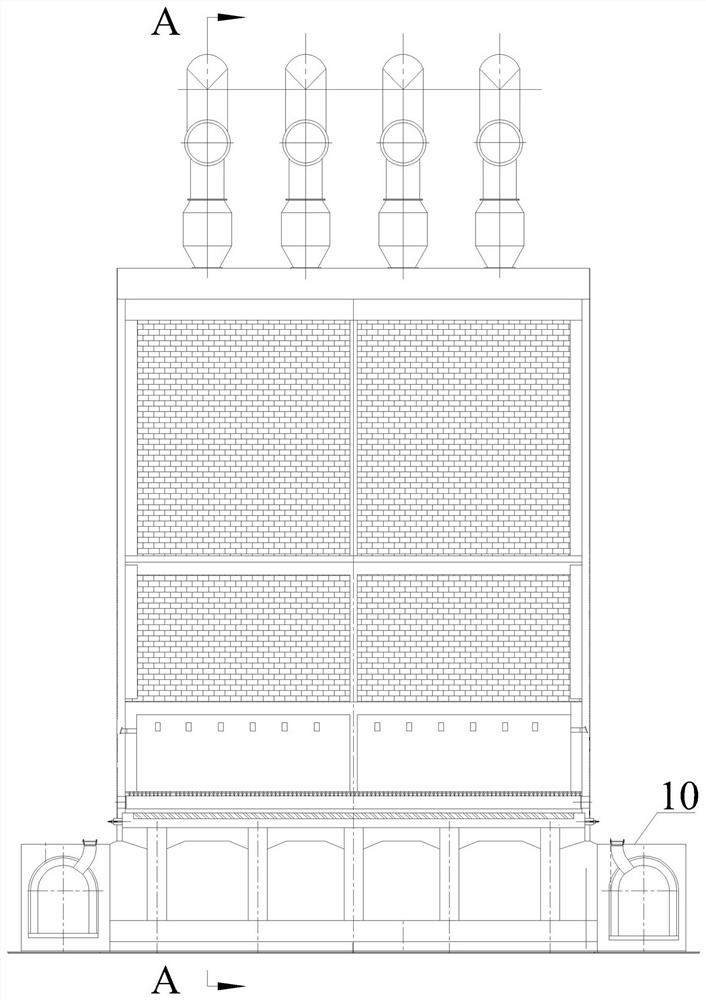

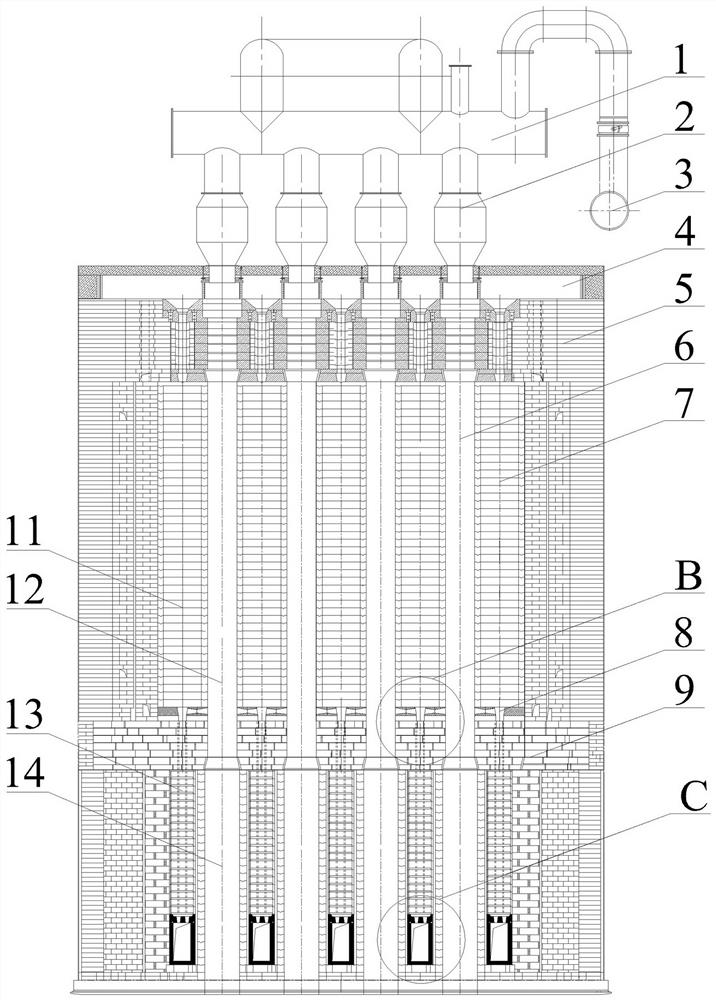

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a VOCs waste gas adsorbent desorption pyrolysis furnace is characterized in that it includes a desorption pyrolysis furnace body 5 and a feeding system 1 .

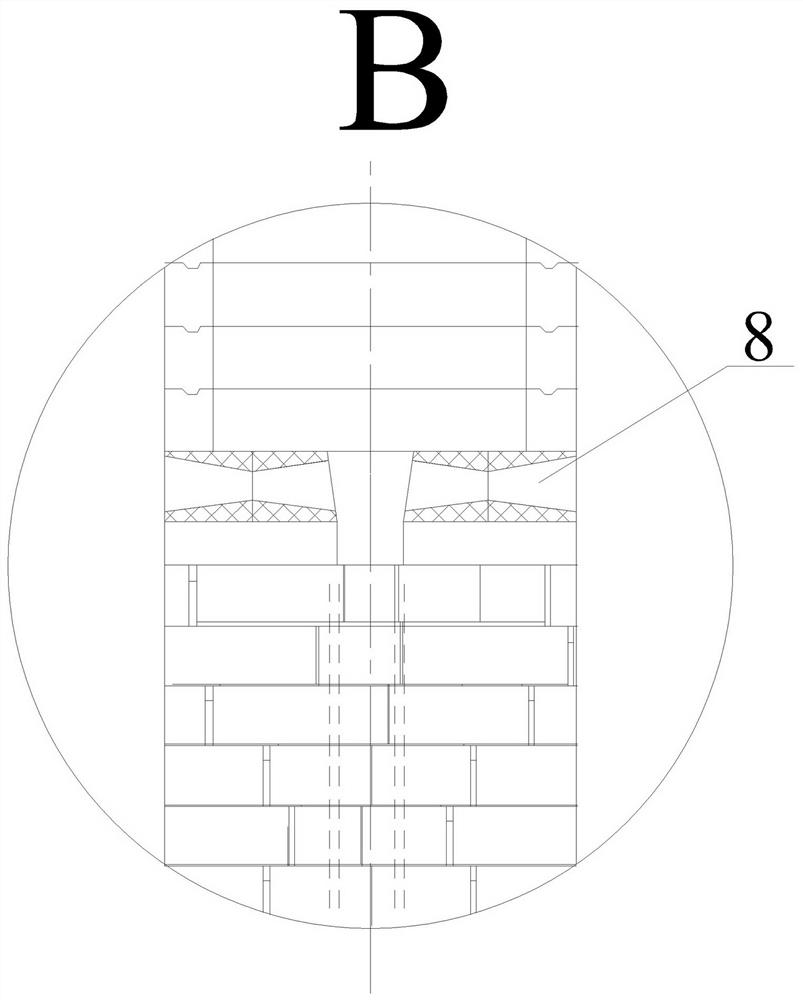

[0023] The desorption pyrolysis furnace body 5 is designed with a fire path 7 and a vertical path 6, the fire path 7 is for the circulation of high-temperature flue gas, the vertical path 6 is for the adsorbent to move and fall, and the fire path 7 and the vertical path 6 are adjacently built. The middle partition arch 9 divides the desorption pyrolysis furnace body 5 into upper and lower areas, that is, the upper area desorption pyrolysis area and the lower area heat storage area.

[0024] The corresponding flue 7 is also divided into upper and lower chambers. The lower chamber is the heat storage chamber 13, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com