Mixing absorption type infrared cut-off filter and preparation method thereof

An infrared cut-off and infrared cut-off film technology, applied in optical filters, optical filters for photography, optics, etc., can solve the high cost and limited resources, the shortage of blue glass raw materials, the difficulty of processing technology, and the high production cost of BGFilter and other problems, to achieve the effect of facilitating large-scale, reducing production costs and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

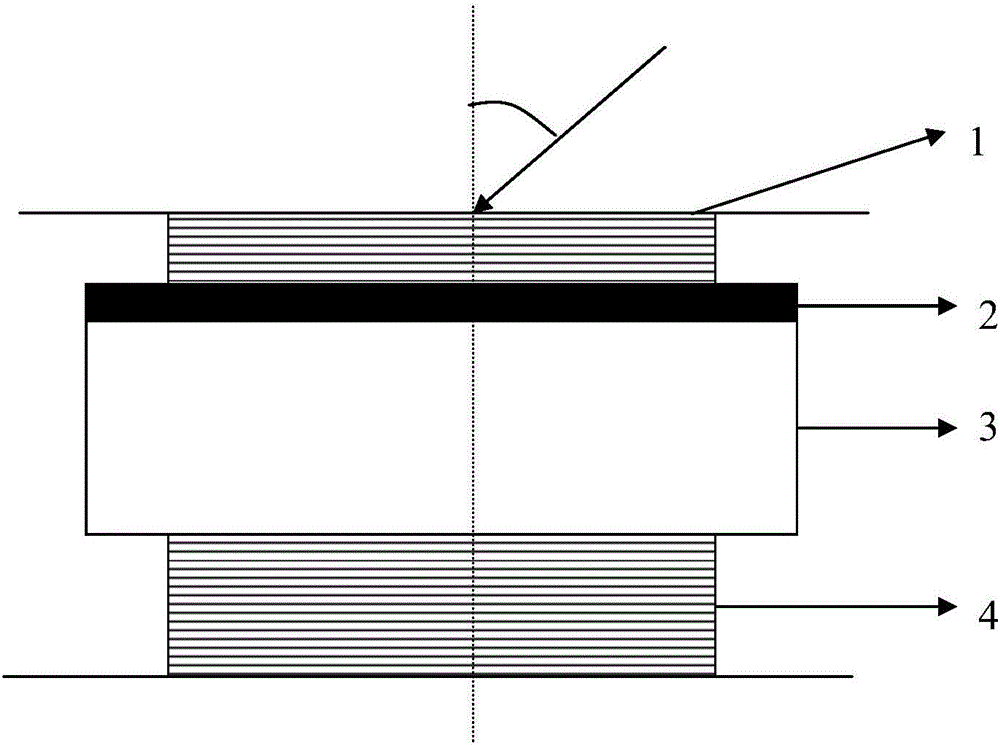

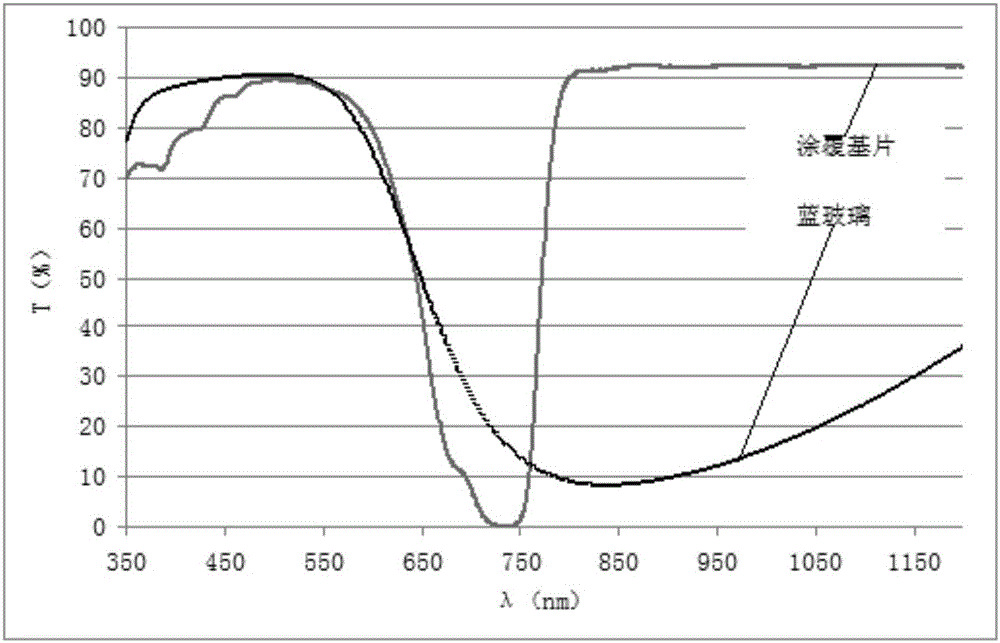

[0031] Such as figure 1 As shown, a mixed absorption infrared cut-off filter is composed of a glass substrate 3 (D263T colorless borosilicate glass), a coating adhesive layer 2 , an anti-reflection film layer 1 and an infrared cut-off film layer 4 . The thickness of the glass substrate is between 0.1mm and 1.0mm, and the commonly used specifications are 0.11mm, 0.21mm, 0.3mm, 0.45mm, 0.7mm, and 1.0mm. The visible light absorption band of the coating glue layer (the glue for coating glue is commercially available from Nippon Shokubai Co., Ltd., model: IX-2-GQ-AE2) is 380-760 nm, and the highest light transmittance T>90%. The coating thickness ranges from 5-100μm. The coating adhesive layer has absorption characteristics in the visible light band (380-760nm), and the use of this absorption characteristic greatly reduces the edge chromatic aberration problem caused by the angle effect. The number of anti-reflection coating layers is 4-7 layers, and the thickness of the anti-ref...

Embodiment 1

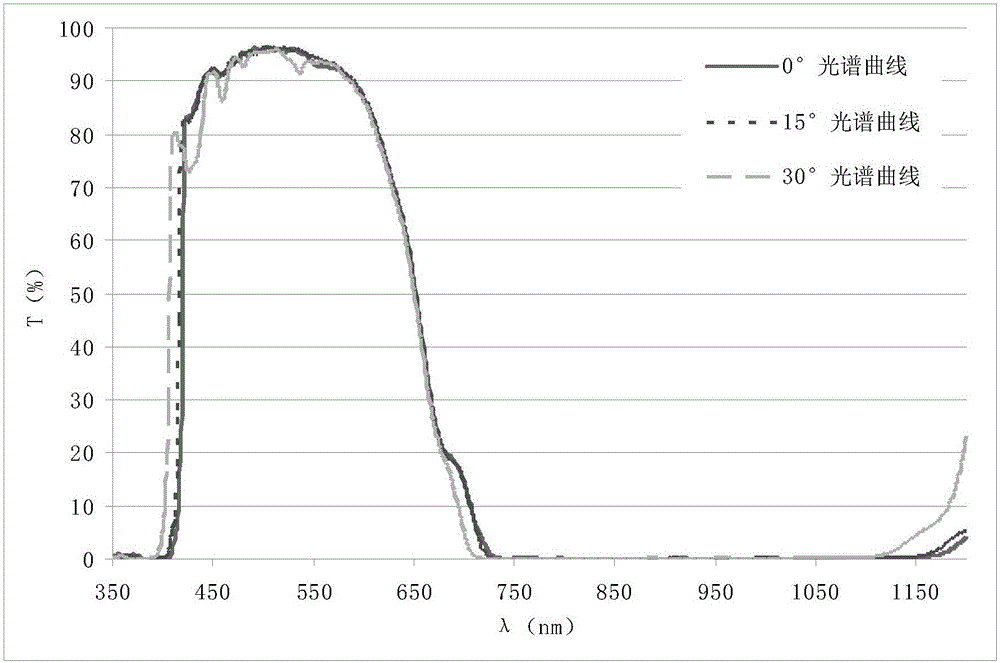

[0038] Curve requirements for a hybrid infrared cut filter: average transmittance T in the visible light band 440-550nm ave >93%, IR center cut-off wavelength T 50% =660±5, 0-30°center offsetave ave max <1%.

[0039]Thickness T = 0.21mm, size Φ = 150mm glass substrate is ultrasonically cleaned, dried and put into the glue homogenizer. Bake in a nitrogen oven with an adjustable flow rate, the nitrogen flow rate is 20-40sccm, take out the measurement after the baking time is 40-80min, and confirm that the coated substrate meets the design requirements.

[0040] Electron gun evaporation and ion source assisted method are used to deposit anti-reflection film layer and infrared cut film layer, in which the evaporation rate of high refractive index material layer is 2-4A / s, and the evaporation rate of low refractive index material layer is 10-14A / s, ion source assisted The voltage BV value is 350-800V, the constant temperature of the substrate is 180-220°C, and the time is 40-80mi...

Embodiment 2

[0043] Curve requirements for a hybrid infrared cut filter: average transmittance T in the visible light band 440-550nm ave >93%, IR center cut-off wavelength T 50% =650±5, 0-30°center offsetave ave max <1%.

[0044] Thickness T = 0.21mm, size Φ = 150mm glass substrate is ultrasonically cleaned, dried and put into the glue homogenizer. Bake in a nitrogen oven with an adjustable flow rate, the nitrogen flow rate is 20-40sccm, take out the measurement after the baking time is 40-80min, and confirm that the coated substrate meets the design requirements.

[0045] Electron gun evaporation and ion source assisted method are used to deposit anti-reflection film layer and infrared cut film layer, in which the evaporation rate of high refractive index material layer is 2-4A / s, and the evaporation rate of low refractive index material layer is 10-14A / s, ion source assisted The voltage BV value is 350-1100V, the constant temperature of the substrate is 130-180°C, and the time is 40-80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com