UHMWPE (Ultra High Molecular Weight Polyethylene Fiber) summer sleeping mat and manufacture method thereof

A polyethylene fiber and ultra-high molecular weight technology, applied in chemical instruments and methods, layered products, textiles and papermaking, etc., can solve problems such as difficult to export sweat and absorb gaseous water, and no patent literature has been found, and achieve easy storage and Washing, avoidance of maceration, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

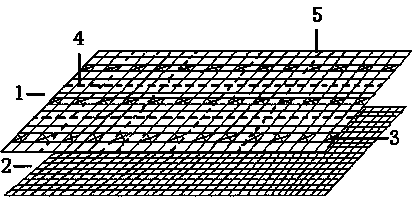

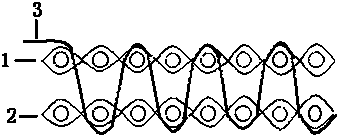

[0048] Such as figure 1 , figure 2 As shown, use 700D / 480f ultra-high molecular weight polyethylene fiber (UHMWPE) white filament yarn, 80 twists / m, S twist, elongation at break 4% as the surface layer (1) warp and weft yarn; use 1000D / 92f blue polyester industrial filament yarn, 60 twists / m, S twist, as the inner layer (2) warp and weft yarns, to ensure that the surface layer (1) yarn and monofilament fineness are higher than the inner layer (2) yarn and The monofilament fineness should be fine. The surface layer (1) and the inner layer (2) adopt the same warp and weft density, 126×142 threads / 10cm. Wherein, every 40cm in the warp direction, empty reed 1cm is used as reserved warp direction folding strip (4); every 30cm in weft direction, empty weft 1cm is used as reserved weft direction folding strip (5). Weave the double-layer weave into one body with warp-direction outer and inner tie lines (3), where every five wefts has a tie point, and weave to obtain a double-laye...

Embodiment 2

[0050] Such as figure 1 , figure 2 As shown, use 1200D / 480f ultra-high molecular weight polyethylene fiber (UHMWPE) white filament yarn, 80 twists / m, S twist, elongation at break 3% as the surface layer (1) warp and weft yarn; use 1200D / 480f blue polyester industrial filament yarn, 60 twists / m, S twist, used as the inner layer (2) warp and weft yarns. The surface layer (1) has a warp and weft density of 126×102 threads / 10cm, and the inner layer (2) has a warp and weft density of 150×102 threads / 10cm, ensuring that the inner layer (1) has smaller pores between yarns and monofilaments than the surface layer (2). Among them, every 30cm in the warp direction and 0.5cm of empty reed are used as reserved warp folding strips (4); every 20cm in weft direction and 0.5cm of empty weft are used as reserved weft folding strips (5). Weaving the double-layer weave into a whole with warp-direction outer and inner knotting lines (3), wherein, every four wefts has a knotting point, weaving...

Embodiment 3

[0052] Such as figure 1 , figure 2 As shown, use 480D / 360f ultra-high molecular weight polyethylene fiber (UHMWPE) white filament yarn, 80 twists / m, S twist, elongation at break 2% as the surface layer (1) warp, ultra-high molecular weight polyethylene Fiber (UHMWPE) and 20s / 2 polyester / linen 40 / 60 yarns are arranged at 1:1 intervals as weft yarns; 20s / 2 polyester / linen 40 / 60 yarns are used as inner layer (2) warp and weft yarns. Among them, the polyester fineness in polyester-linen blended yarn is 2.5D. The warp and weft density of the outer and inner layers is 220×165 threads / 10cm, ensuring that the yarns and the pores in the inner layer (2) are smaller than those in the outer layer (1). Among them, every 20cm in the warp direction and 1cm of empty reed are used as reserved warp folding strips (4); every 50cm in weft direction and 1cm of empty weft are used as reserved weft folding strips (5). Weave the double-layer weave with the outer and inner tie lines (3) in the war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com