Solar cell adopting metal transparent electrode and preparation of solar cell

A technology of solar cells and transparent electrodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as high cost, poor conductivity, poor flexibility, and harsh preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A solar cell using a metal transparent electrode, comprising: a metal counter electrode layer 112 , a metal transparent electrode layer 102 and an active perovskite layer 108 located between the metal counter electrode layer 112 and the metal transparent electrode layer 102 .

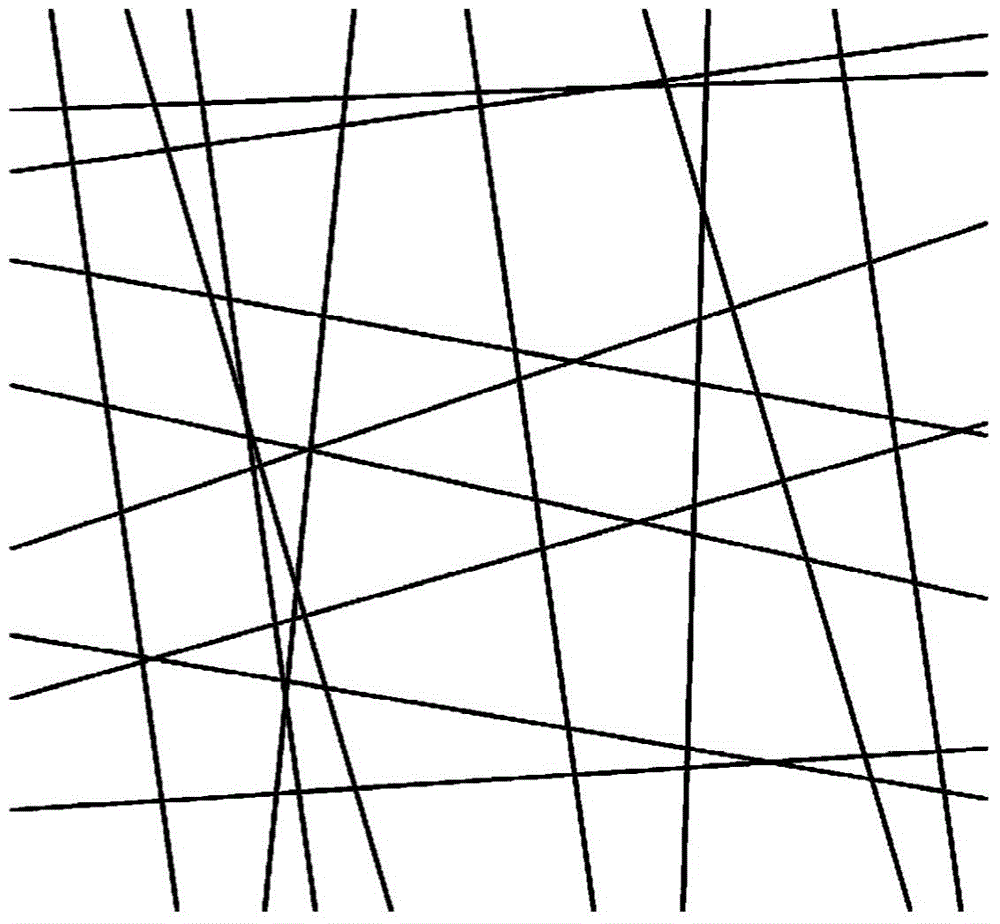

[0030] The metal transparent electrode layer 102 is a metal nanowire mesh conductive film, the metal is Cu, Fe, Ni, Ag, Au or Pt, etc., the diameter of the nanowire is 10-100nm, and the aspect ratio of the nanowire is more than 1000:1. Further, it can have a higher aspect ratio such as 10000:1 to ensure that it has better light transmission performance and certain electrical conductivity. The metal nanowires have a random network structure, such as image 3 As shown, each black line represents a metal nanowire with a diameter of 10-100 nm. If photolithography, nano-etching, atomic deposition, vapor deposition, magnetron sputtering, thermal evaporation, etc. are used, the corresponding template c...

Embodiment 2

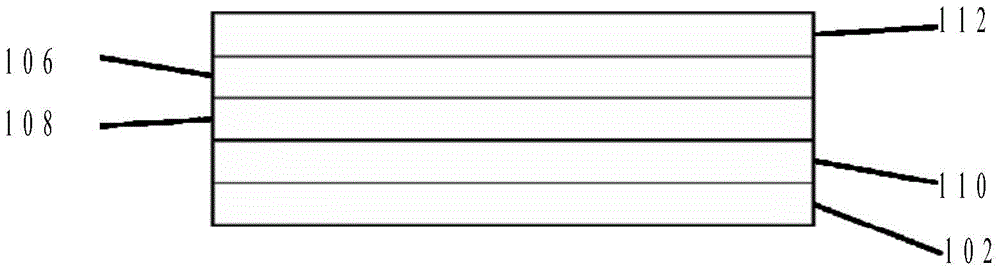

[0038] like figure 1As shown, on the basis of Embodiment 1, an electron transport layer 106 is provided between the metal counter electrode layer 112 and the active perovskite layer 108, and a hole transport layer 110 is provided between the metal transparent electrode layer 102 and the active perovskite layer 108. .

[0039] The electron transport layer 106 is usually made of mesoporous titanium dioxide, which is prepared by annealing and sintering after preparing a sol of mesoscopic particles by a sol-gel method. A fullerene-based electron transport layer material may also be used instead. The thickness of this layer is 100-2000nm.

[0040] The hole transport layer 110 is characterized by organic and inorganic materials that match the energy level of the perovskite active material, such as cuprous iodide, PEDOT:PSS, polyparaphenylene vinylene, polythiophene, polysilane, Triphenylmethanes, triarylamines, hydrazones, pyrazolines, azoles, carbazoles, butadiene, etc., the thi...

Embodiment 3

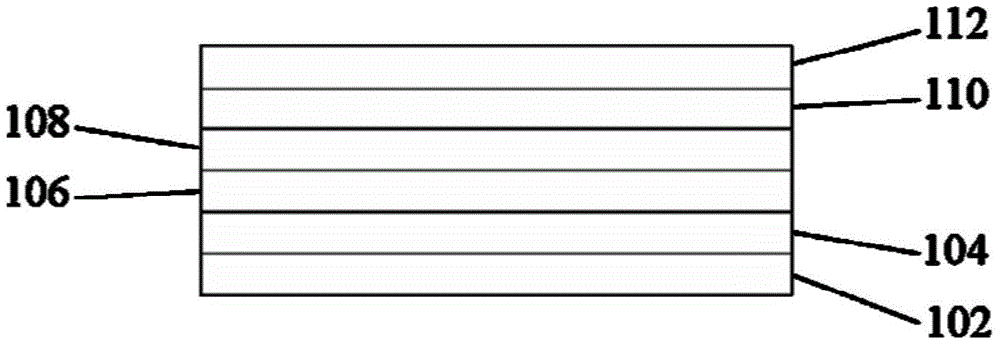

[0048] like figure 2 As shown, on the basis of Embodiment 1, a hole transport layer 110 is provided between the metal counter electrode layer 112 and the active perovskite layer 108, and an electron transport layer 106 or A dense semiconductor layer 104 is disposed between the porous support layer, the electron transport layer 106 or the porous support layer and the metal transparent electrode layer 102 .

[0049] The semiconductor dense layer 104 is usually titanium dioxide or zinc oxide, and its thickness is 20-150 nm.

[0050] If the semiconductor dense layer 104 and the hole transport layer 110 are not provided, the process can be simplified and the cost can be reduced, but the cell efficiency obtained is relatively low.

[0051] The principle of this embodiment:

[0052] 1. Metal transparent electrode layer 102: collects and conducts the electrons conducted by the semiconductor dense layer 104 (if used) or the electron transport layer 106 (if the material layer 104 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com