Method for preparing beta-Al2O3 precursor powder by spray drying taking water as medium

A spray drying method and technology of precursor powder, which is applied in the field of preparing beta-Al2O3 precursor powder by spray drying, can solve the problems of high requirements on equipment sealing and complicated operation, and achieve good reactivity, uniform particle size distribution and fluidity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

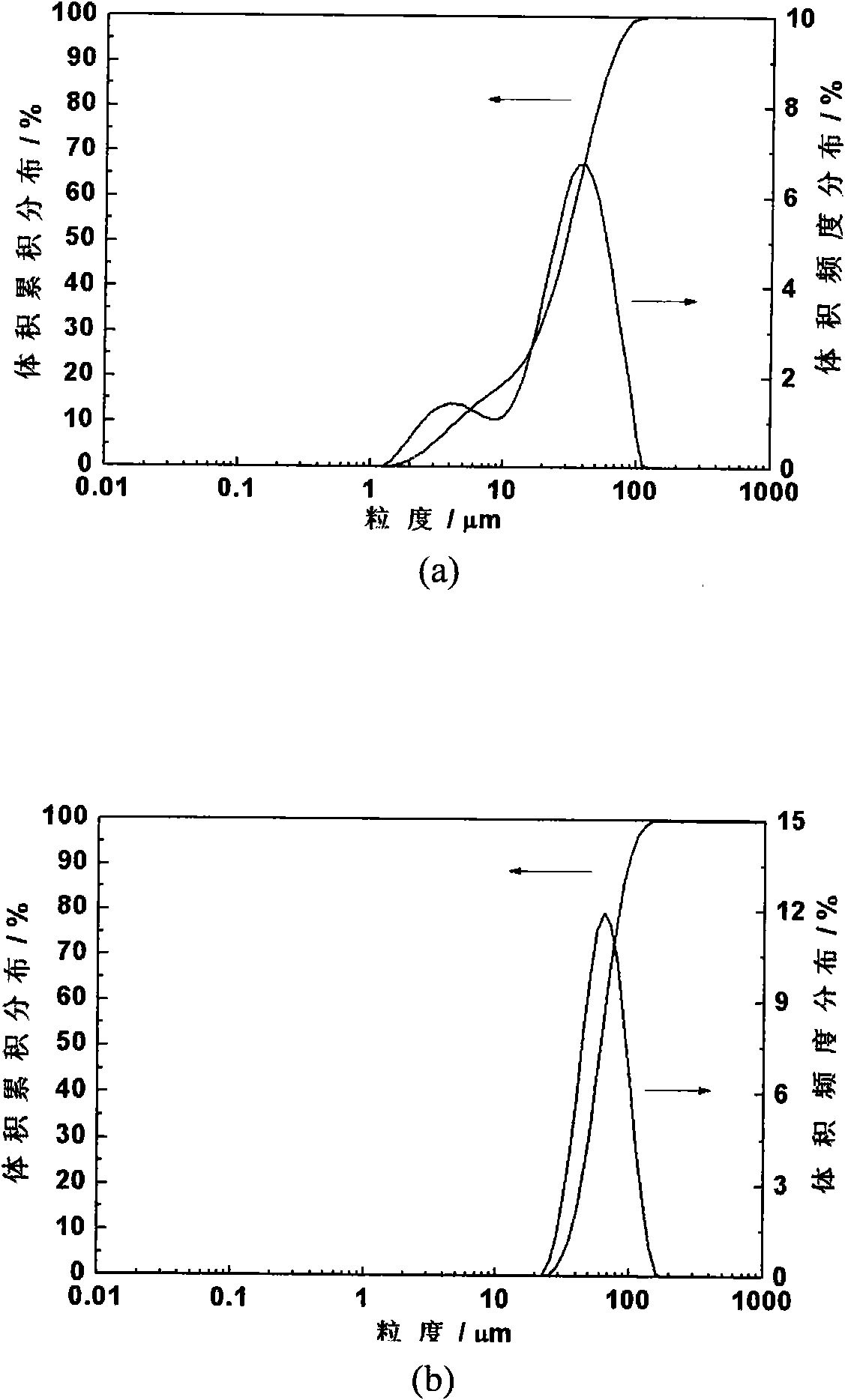

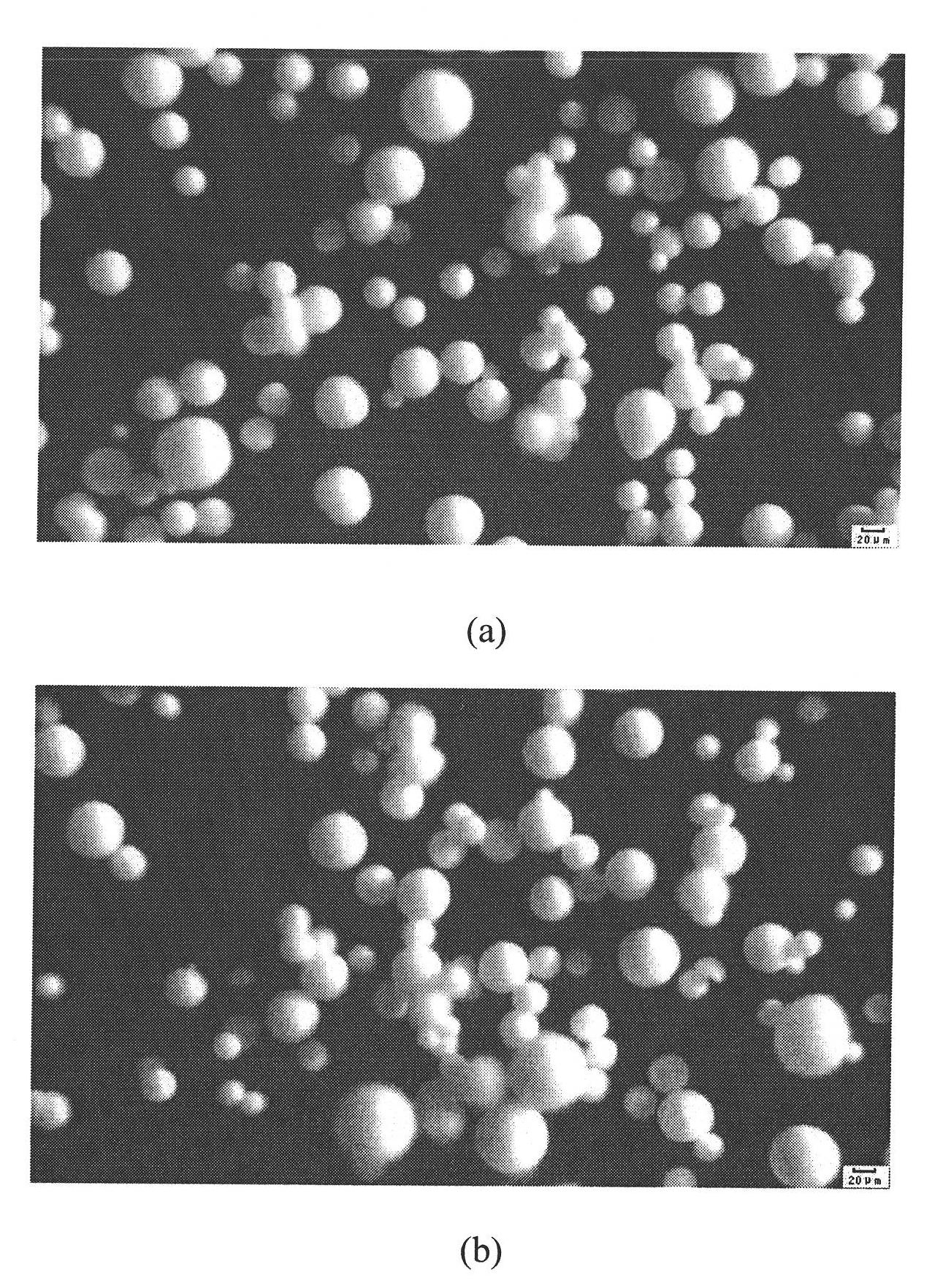

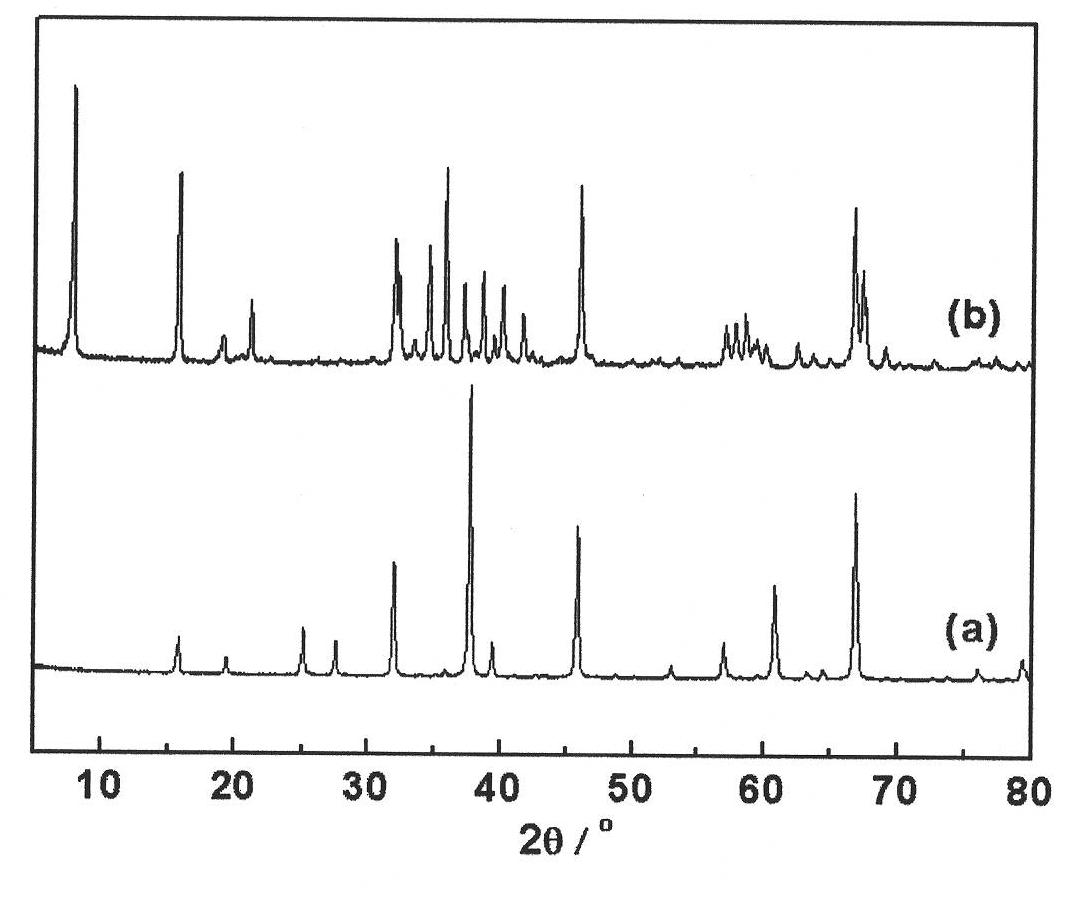

[0015] Weigh a certain amount of α-Al 2 o 3 and Na 2 C 2 o 4 According to Na 2 O:Al 2 o 3 =1:7.6 ratio mixing ball mill, with deionized water as the ball milling medium, the mass ratio of solid raw material and deionized water is 1:1. After 4 hours of ball milling, the obtained slurry is spray-dried. The hot air inlet temperature of the spray drying equipment is 230°C, the outlet temperature is 120°C, the rotation speed of the atomizing disc is 10000r / min, and the feeding rate is automatically controlled according to the temperature. Material 8kg. The obtained raw material powder particles have good sphericity and strong fluidity, the volume average particle size is about 26.1μm, and the specific surface area is 2.25m 2 / g. After the spray-dried powder is packaged, it is calcined at 1250°C for 2 hours to obtain the Na precursor powder. The Na precursor powder synthesized at high temperature still has good sphericity, light agglomeration, and can retain high sintering...

Embodiment 2

[0017] Weigh a certain amount of α-Al 2 o 3 and NaOH according to Na 2 O:Al 2 o 3 =1:7.5 ratio mixed ball mill, with deionized water as the ball milling medium, the mass ratio of solid raw material and deionized water is 1:1. After ball milling for 6 hours, spray dry the obtained slurry. The hot air inlet temperature of the spray drying equipment is 230°C, the outlet temperature is 120°C, the rotation speed of the atomizing disc is 10000r / min, and the feeding rate is automatically controlled according to the temperature. Material 7.5kg. Due to the high solubility of NaOH in water, the viscosity of the slurry prepared with NaOH as the Na source is lower than that of the slurry prepared with NaOH under the same solid content. 2 C 2 o 4For the Na source slurry, the lower viscosity is conducive to the delivery of the slurry during the spraying process and the stable control of the machinery and equipment. The volume average particle size of the powder obtained by spraying ...

Embodiment 3

[0019] Weigh a certain amount of α-Al 2 o 3 and Na 2 C 2 o 4 According to Na 2 O:Al 2 o 3 =1:7.6 ratio mixing ball mill, with deionized water as the ball milling medium, the mass ratio of solid raw material and deionized water is 0.8:1. After 4 hours of ball milling, the obtained slurry is spray-dried. The hot air inlet temperature of the spray drying equipment is 250°C, the outlet temperature is 125°C, the rotation speed of the atomizing disc is 10000r / min, and the feeding rate is automatically controlled according to the temperature. Material 5.5kg. Increasing the amount of deionized water in the process of ball milling reduces the solid content of the slurry, but can make α-Al 2 o 3 with Na 2 C 2 o 4 The raw materials are mixed more evenly, the viscosity of the slurry is correspondingly reduced, and the fluidity is enhanced, which is conducive to the smooth progress of the spraying process. The raw material powder obtained after spray drying has good sphericity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com