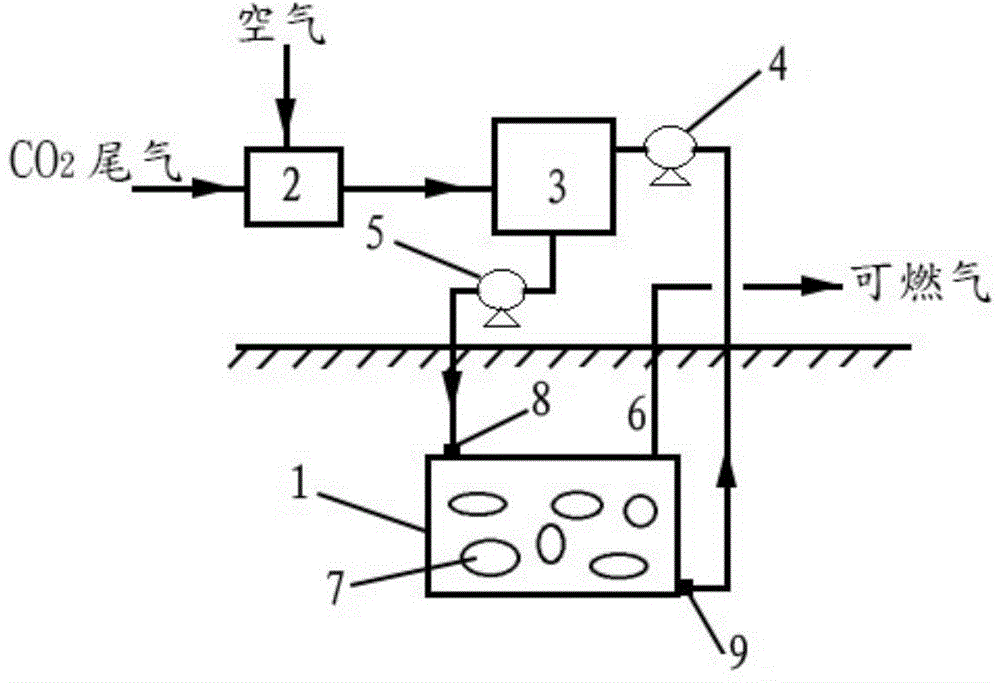

Coal-mine-goaf-based carbon dioxide underground sealing method and system

A carbon dioxide, goaf technology, applied in biochemical equipment and methods, biochemical instruments, biochemical cleaning devices, etc., can solve the problems of water pollution, large energy consumption, overflow, etc., to avoid water pollution, reduce storage costs, To achieve the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

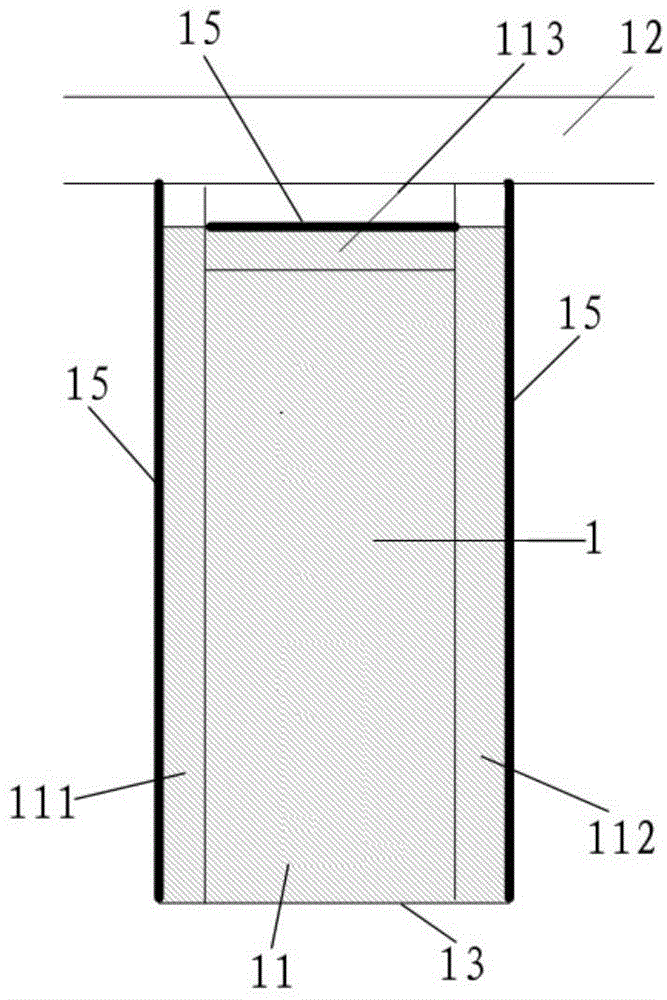

[0065] The flue gas of a power plant exchanges heat with the water drawn from the outlet of the underground confined space 1 formed in the goaf area of a coal mine, and then mixes it with air at a ratio of 1:10 to obtain CO 2 The mixed gas with a concentration of about 2% and an oxygen concentration of about 19% is sent to the microalgae breeding unit 3 for microalgae propagation. When the concentration of microalgae in the algae-containing aqueous solution is greater than 5g / L, the algae-containing aqueous solution is injected into the underground confined space 1 through the water injection port 8. After being adsorbed and filtered by the falling rock mass 7 in the underground confined space 1, it is removed from the underground confined space 1 The aqueous solution coming out of the drainage port 9 basically does not contain microalgae, and the microalgae is mainly adsorbed in the falling rock mass 7 of the underground confined space 1, realizing the protection of CO 2 Fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com