Wall breaking method for extracting fruit, vegetable and grain powder

A technology of grain powder, fruit and vegetable, which is applied in the field of wall breaking, can solve the problems of not being able to meet the use requirements, protein inactivation, incomplete wall breaking, etc., and achieve the effect of convenient operation, complete wall breaking, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

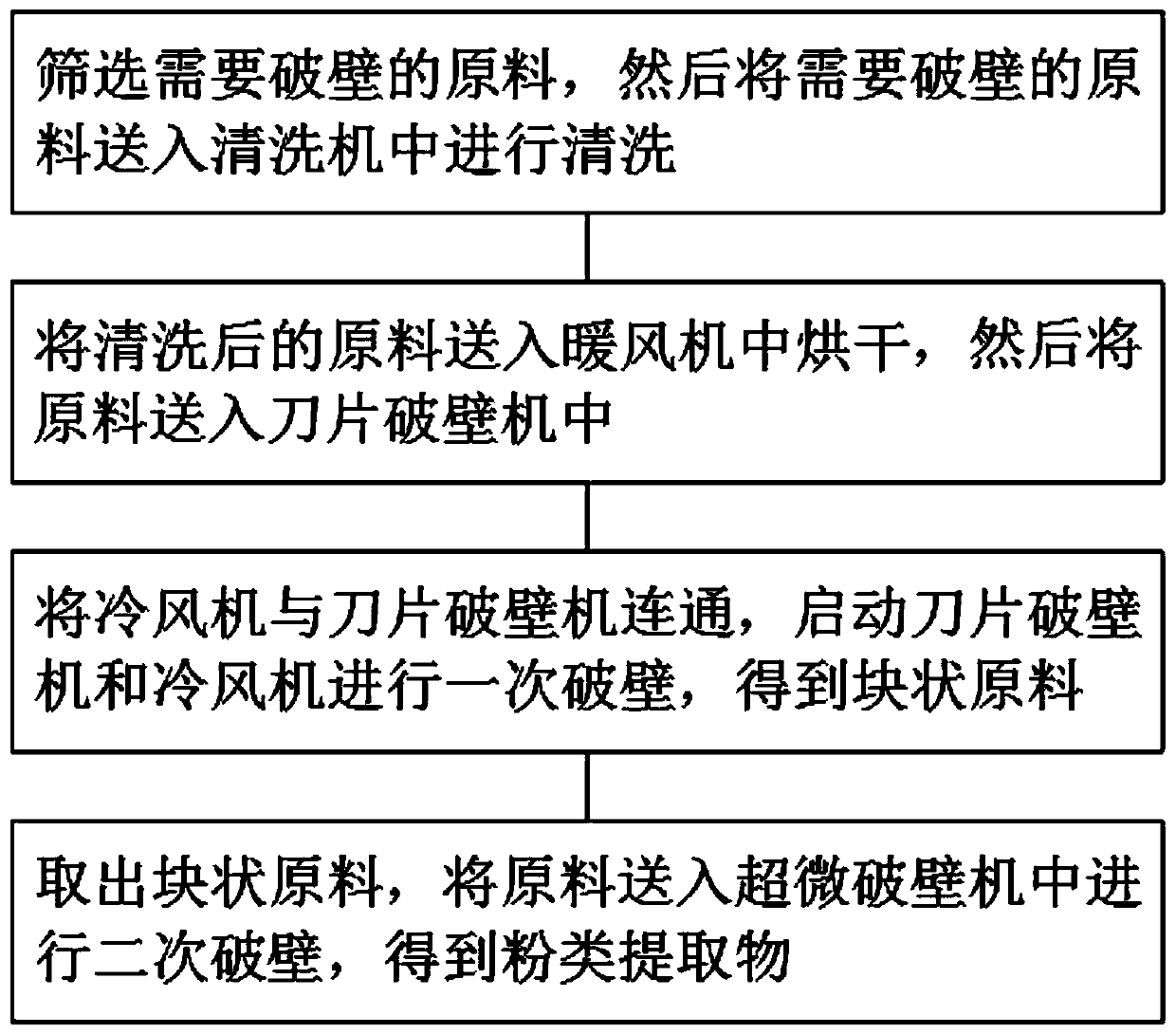

[0026] A wall-breaking method for extracting fruit and vegetable grain powders, comprising the following steps:

[0027] (1), screen the raw materials that need to be broken, and then send the raw materials that need to be broken into the washing machine for cleaning;

[0028] The steps of screening the broken wall raw materials are:

[0029] ①. Send the broken raw materials into the color sorter for color sorting, and remove the raw materials with different skin colors;

[0030] ②. The raw materials after color selection are sent to the screening machine, and the raw materials with different weights are eliminated;

[0031] During cleaning, the water temperature of the cleaning machine is 25°C, and the cleaning is performed for 12 minutes. During cleaning, the stirring equipment is used to stir for 6 minutes, and the stirring rate is 30 r / min.

[0032] (2), the raw material after cleaning is sent into the heater for drying, and then the raw material is sent into the blade w...

Embodiment 2

[0041] A wall-breaking method for extracting fruit and vegetable grain powders, comprising the following steps:

[0042] (1), screen the raw materials that need to be broken, and then send the raw materials that need to be broken into the washing machine for cleaning;

[0043] The steps of screening the broken wall raw materials are:

[0044] ①. Send the broken raw materials into the color sorter for color sorting, and remove the raw materials with different skin colors;

[0045] ②. The raw materials after color selection are sent to the screening machine, and the raw materials with different weights are eliminated;

[0046] During cleaning, the water temperature of the cleaning machine is 25°C, and the cleaning is performed for 12 minutes. During cleaning, the stirring equipment is used to stir for 6 minutes, and the stirring rate is 30 r / min.

[0047] (2), the raw material after cleaning is sent into the heater for drying, and then the raw material is sent into the blade w...

Embodiment 3

[0056] A wall-breaking method for extracting fruit and vegetable grain powders, comprising the following steps:

[0057] (1), screen the raw materials that need to be broken, and then send the raw materials that need to be broken into the washing machine for cleaning;

[0058] The steps of screening the broken wall raw materials are:

[0059] ①. Send the broken raw materials into the color sorter for color sorting, and remove the raw materials with different skin colors;

[0060] ②. The raw materials after color selection are sent to the screening machine, and the raw materials with different weights are eliminated;

[0061] During cleaning, the water temperature of the cleaning machine is 25°C, and the cleaning is performed for 12 minutes. During cleaning, the stirring equipment is used to stir for 6 minutes, and the stirring rate is 30 r / min.

[0062] (2), the raw material after cleaning is sent into the heater for drying, and then the raw material is sent into the blade w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com