Balanced fluid grinding machine

A grinding machine and balanced technology, which is applied in the direction of grinding frame, grinding machine parts, grinding machines, etc., can solve the problems that the surface treatment efficiency is difficult to meet the production demand, the grinding quality is limited, and the abrasive fluidity is poor, and the grinding quality can be achieved. Good, improve the grinding effect, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

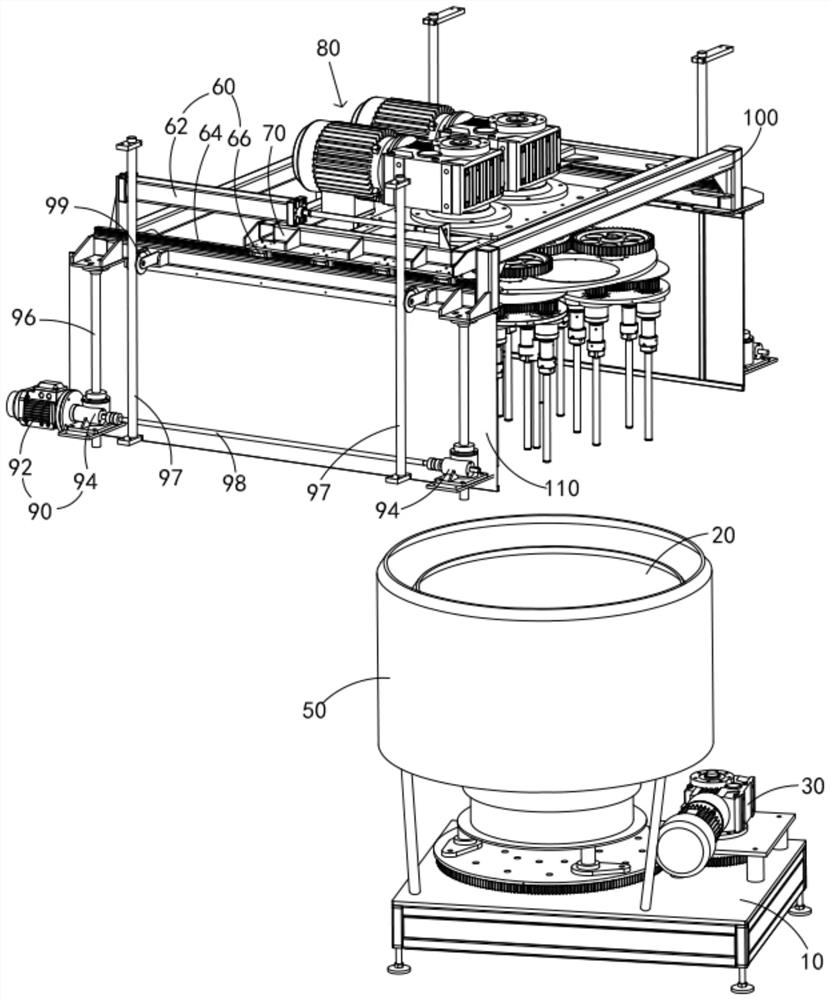

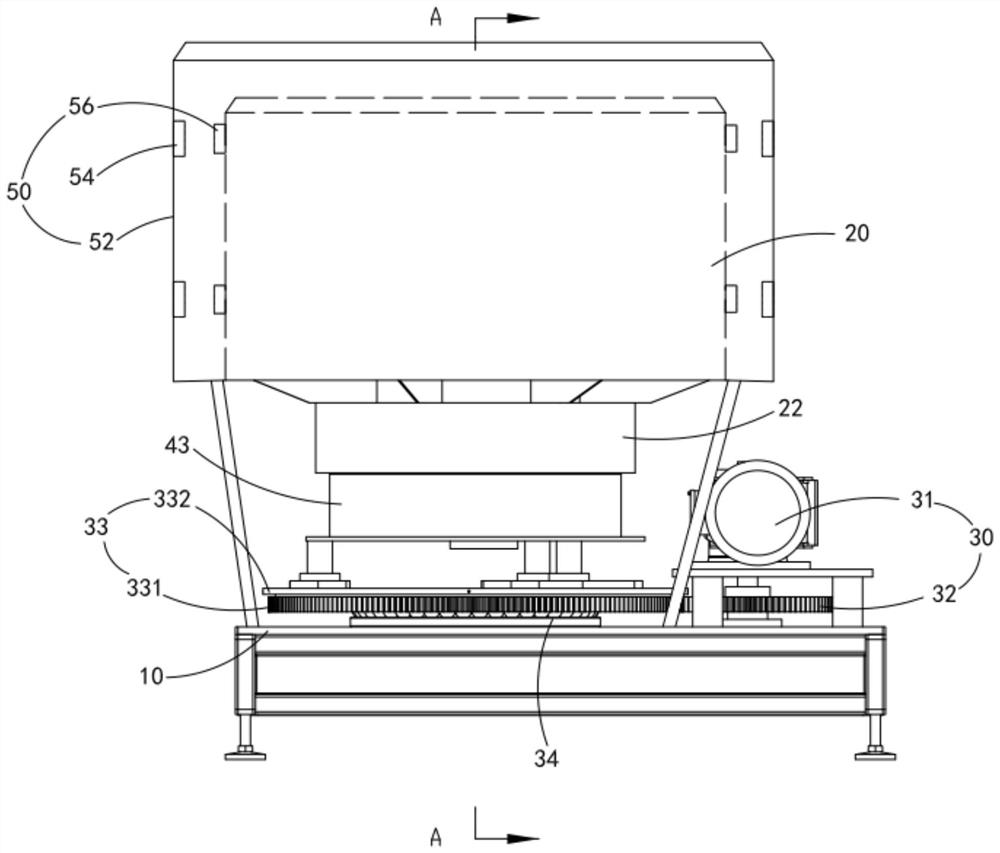

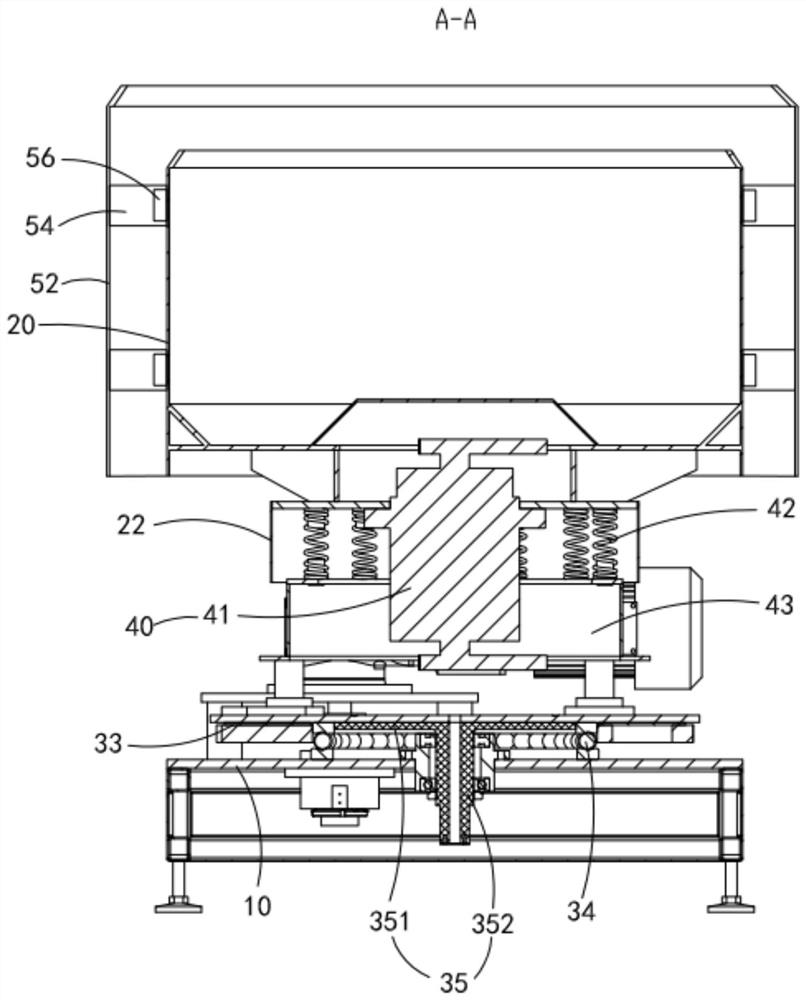

[0021] Please refer to figure 1 , figure 2 and image 3 , the balanced fluid grinder includes a horizontal moving mechanism 60, and a moving frame 70 connected with the horizontal moving mechanism 60, the moving frame 70 is provided with a rod driving mechanism 80, and the horizontal moving mechanism 60 is used to drive the moving frame 70 to perform reciprocating motion;

[0022] It also includes an abrasive chamber mechanism located below the rod driving mechanism 80 , the abrasive chamber mechanism includes a bottom plate 10 , a box body 20 , a rotating assembly 30 , a vibrating assembly 40 and a balancing assembly 50 .

[0023] The vibrating component 40 is disposed on the box body 20 , and the vibrating component 40 is used to drive the box body 20 to vibrate.

[0024] The rotating assembly 30 is disposed on the bottom plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com