Bacteriostatic filter element

A filter element and filter bottle technology, applied in filtration treatment, sterilization/microdynamic water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as inability to form effective sterilization, large pressure difference, and reverse sterilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

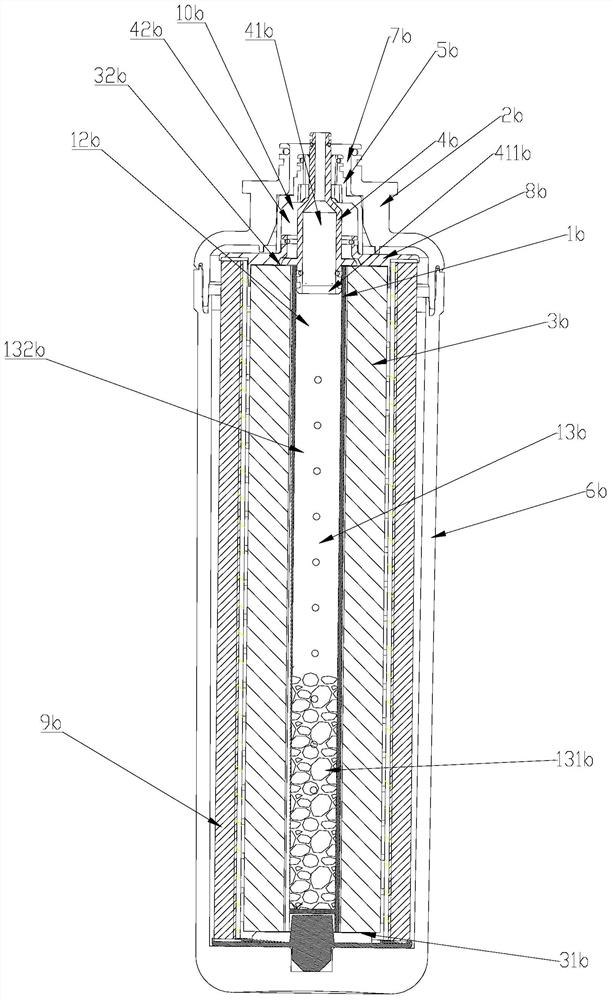

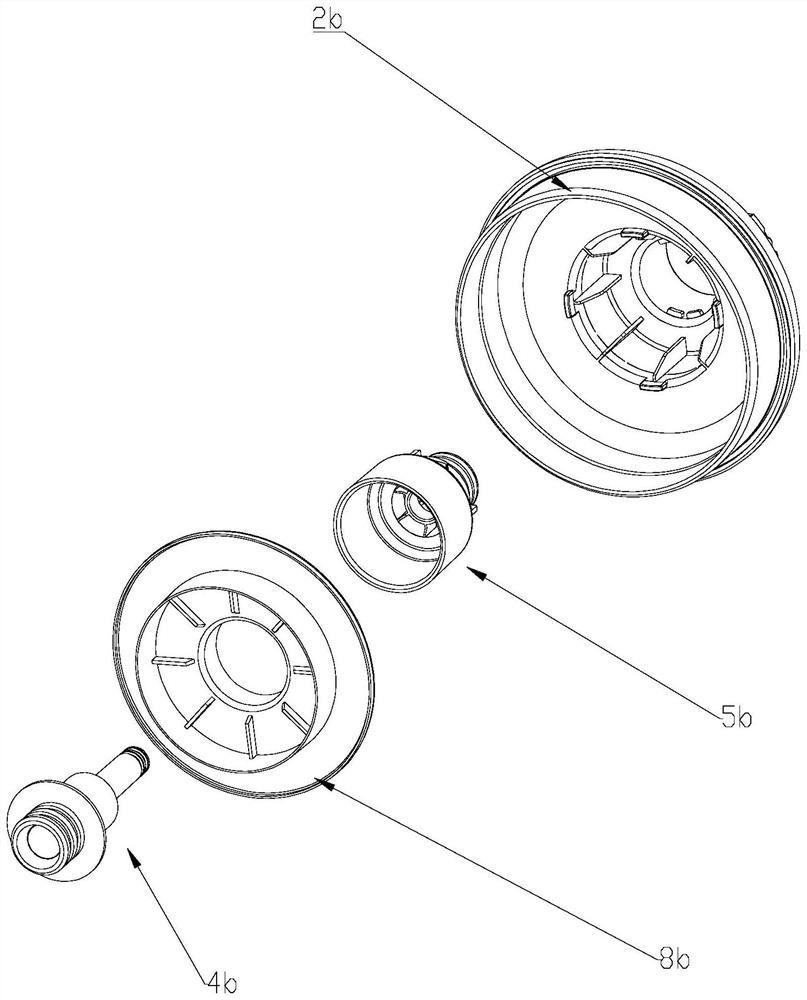

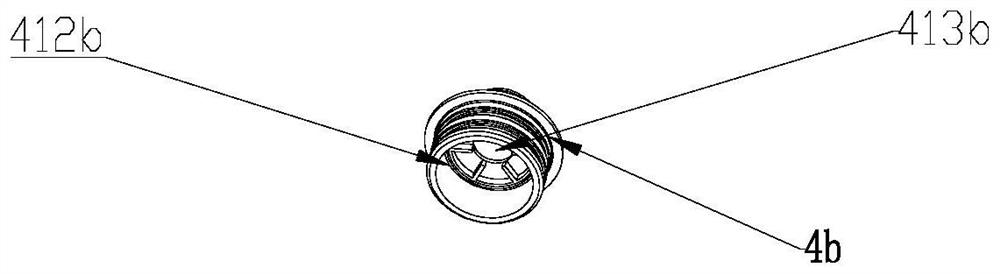

[0035] This application is as Figure 1-4 As shown, the antibacterial filter element is provided in the filter bottle housing 6b, the application also includes a reverse osmosis membrane 3b, the reverse osmosis membrane 3b is wound on the outer periphery of the central pipe 1b, and one end of the roll film of the reverse osmosis membrane 3b forms an axial flow of raw water The other end of the water inlet area 31b forms an axial flow concentrated water drainage area 32b, and the raw water inlet area 31b is located on the side away from the water outlet end 12b of the central pipe 1b. When the antibacterial filter element starts to work, the pressure of the raw water inlet area 31b is higher than the pressure of the concentrated water discharge area 32b, so that a water pressure change is formed in the overflow channel 13b, and the pressure from the filling area 131b to the turbulence area 132b is from large to small. The bacteriostatic particles are turbulently rolled from the...

Embodiment 2

[0060] like Figure 5 As shown, the difference between this embodiment and the first embodiment is that in this embodiment, the cross-sectional areas of the flow passages are not uniformly arranged along the axial direction, but gradually increase from bottom to top along the axial direction. Wherein, the wall of the central tube 1a has a radial increase from the bottom filling area to the upper turbulent area, and the axial inclined extension angle of the central tube wall is α, and the angle of α ranges from 2° to 5°, preferably 3°. When the center tube is formed, the α angle can be set through the demolding direction of the mold, as in this embodiment Figure 5 The filling area is located at the bottom of the center tube, and the top of the flow area is formed with an opening of the water outlet end of the center tube. After the glue is injected, the mold is drawn from the filling area to the direction of the flow area in the demolding direction, and the molding process of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com