Anti-tearing biochemical protective clothes with antibacterial function and making method thereof

A technology for anti-tearing and protective clothing, applied in the direction of protective clothing, clothing, clothing, etc., can solve the problems of physical adsorption and desorption, achieve good antibacterial properties, high anti-tearing performance, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

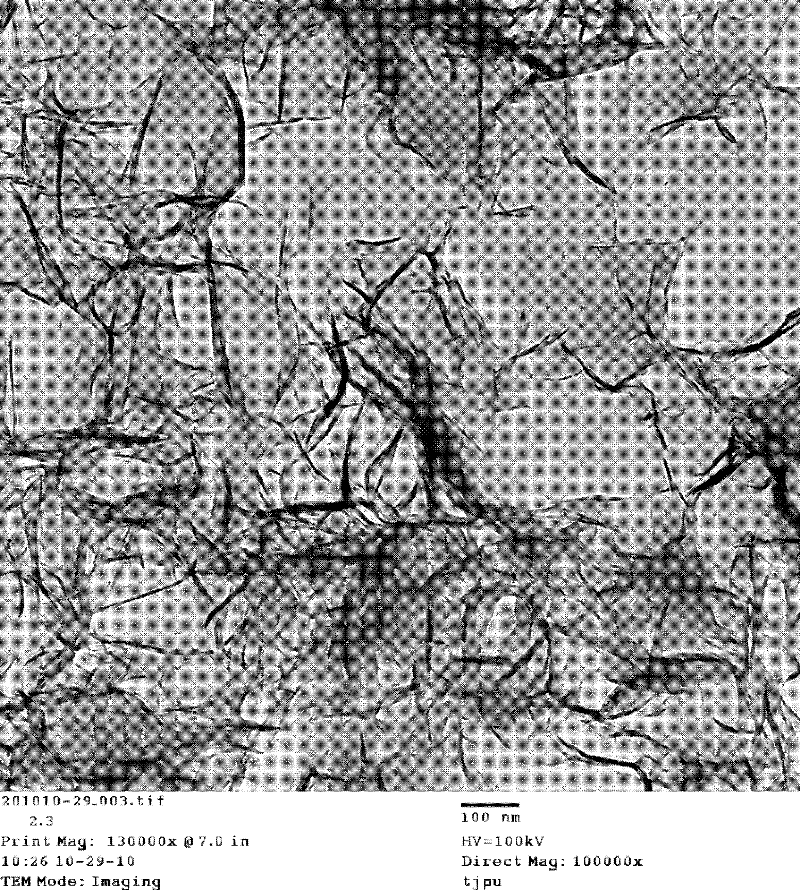

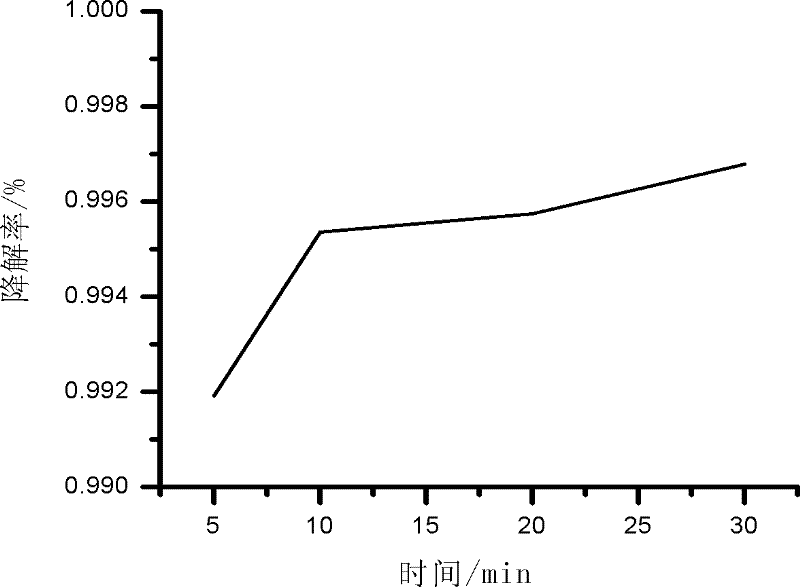

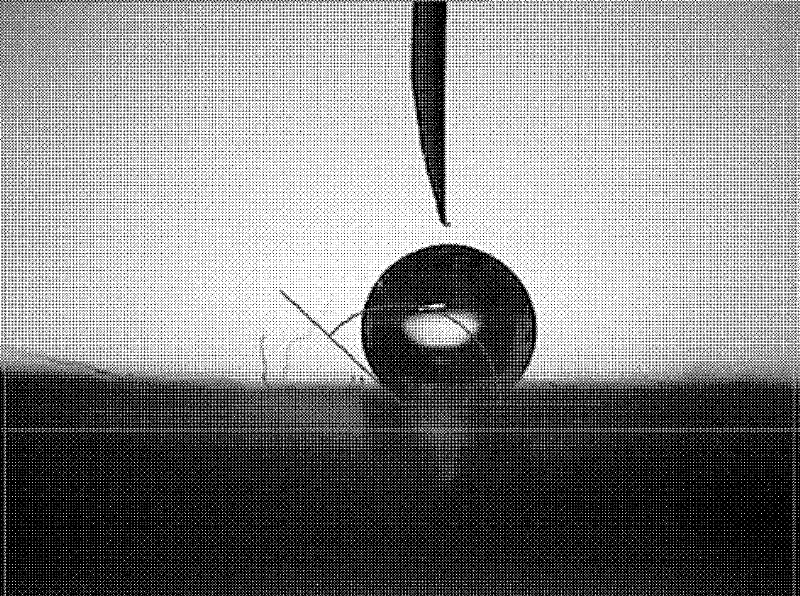

[0021] In 0.1L of magnesium chloride absolute ethanol solution with a concentration of 0.4mol / L, add 5ml of dispersant polyethylene glycol and 0.015mol of acetic acid, place in a constant temperature water bath at 60°C and mix evenly, under continuous magnetic stirring, slowly add ammonia water and Anhydrous ethanol mixed solution, a white precipitate is formed. After the dropwise addition was completed, the temperature was maintained to continue the reaction for a period of time, the precipitate was filtered, washed and then vacuum-dried to obtain a white precursor. Calcined at 550°C for 2 hours after grinding to obtain nano magnesium oxide powder. The polyester / vinylon blended ripstop fabric that has been treated for water repellency and oil repellency is used as the outer layer, 35g / m 2 The polypropylene melt-blown non-woven fabric is used as the middle layer, and the mesh lining is used as the inner layer. The prepared nano-magnesium oxide is added to the middle of the th...

Embodiment 2

[0023] In 0.1L magnesium chloride absolute ethanol solution with a concentration of 0.2mol / L, add 10ml dispersant polyethylene glycol and 0.01mol acetic acid, place in a constant temperature water bath at 60°C and mix evenly, under continuous magnetic stirring, slowly add ammonia water and Anhydrous ethanol mixed solution, a white precipitate is formed. After the dropwise addition, keep the temperature to continue the reaction for a period of time, and let stand at room temperature for 8h. The precipitate was filtered, washed and dried in vacuum to obtain a white precursor. After grinding, it was calcined at 550°C for 2 hours to obtain nano-magnesia powder. The polyester / vinylon blended ripstop cloth that has been waterproof and oil-repellent is used as the outer layer, the polytetrafluoroethylene composite film is the middle layer, and the mesh lining is the inner layer. The prepared nano-magnesium oxide is added to the middle layer of the three layers for layering. Prepara...

Embodiment 3

[0025] In 0.1L of magnesium chloride absolute ethanol solution with a concentration of 0.4mol / L, add 5ml of dispersant polyethylene glycol and 0.015mol of acetic acid, place in a constant temperature water bath at 60°C and mix evenly, under continuous magnetic stirring, slowly add ammonia water and no Mixed solution of water and ethanol, a white precipitate is formed. After the dropwise addition was completed, the temperature was maintained to continue the reaction for a period of time, the precipitate was filtered, washed and then vacuum-dried to obtain a white precursor. Calcined at 550°C for 2 hours after grinding to obtain nano magnesium oxide powder. The polyester / vinylon blended ripstop cloth that has been waterproof and oil-repellent is used as the outer layer, the polytetrafluoroethylene composite film is the middle layer, and the mesh lining is the inner layer. The prepared nano-magnesium oxide is added to the middle layer of the three layers for layering. Preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com