Nozzle structure for multi-point injection of heavy methanol engine

A methanol engine and engine cylinder technology, which is applied to engine components, machines/engines, fuel injection devices, etc., can solve the problems of difficult development of large flow nozzles, insufficient control accuracy of small flow, low combustion efficiency, etc., to improve control accuracy. and combustion efficiency, improve atomization effect, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

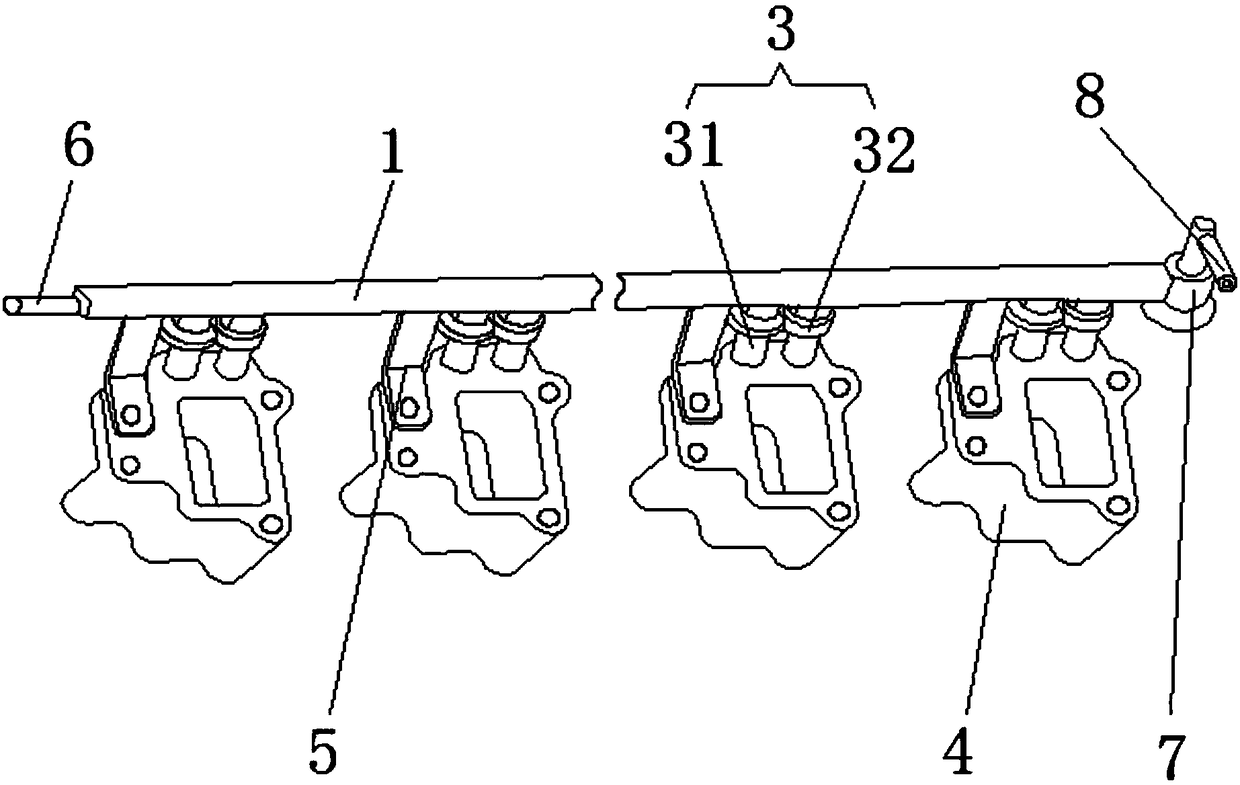

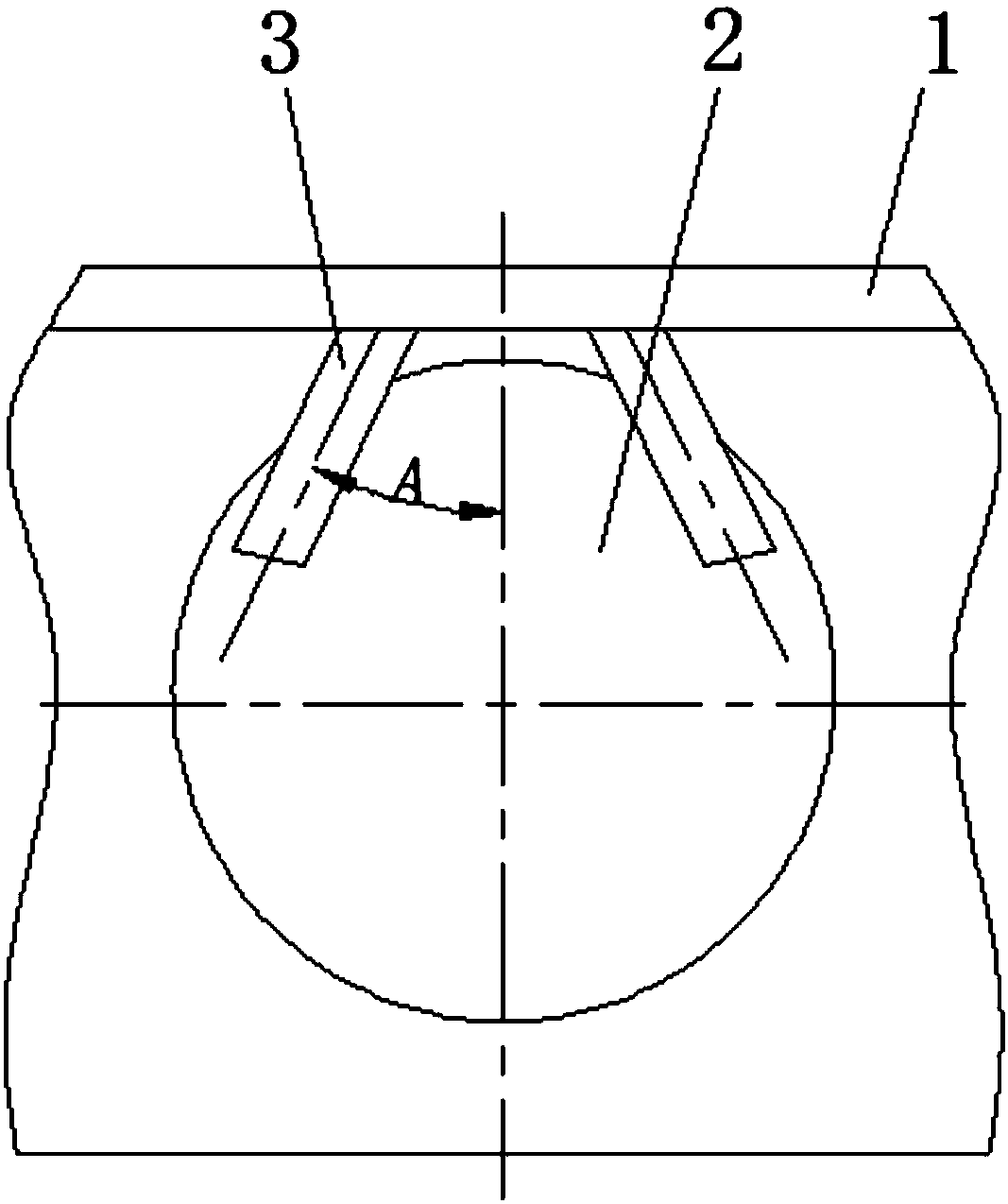

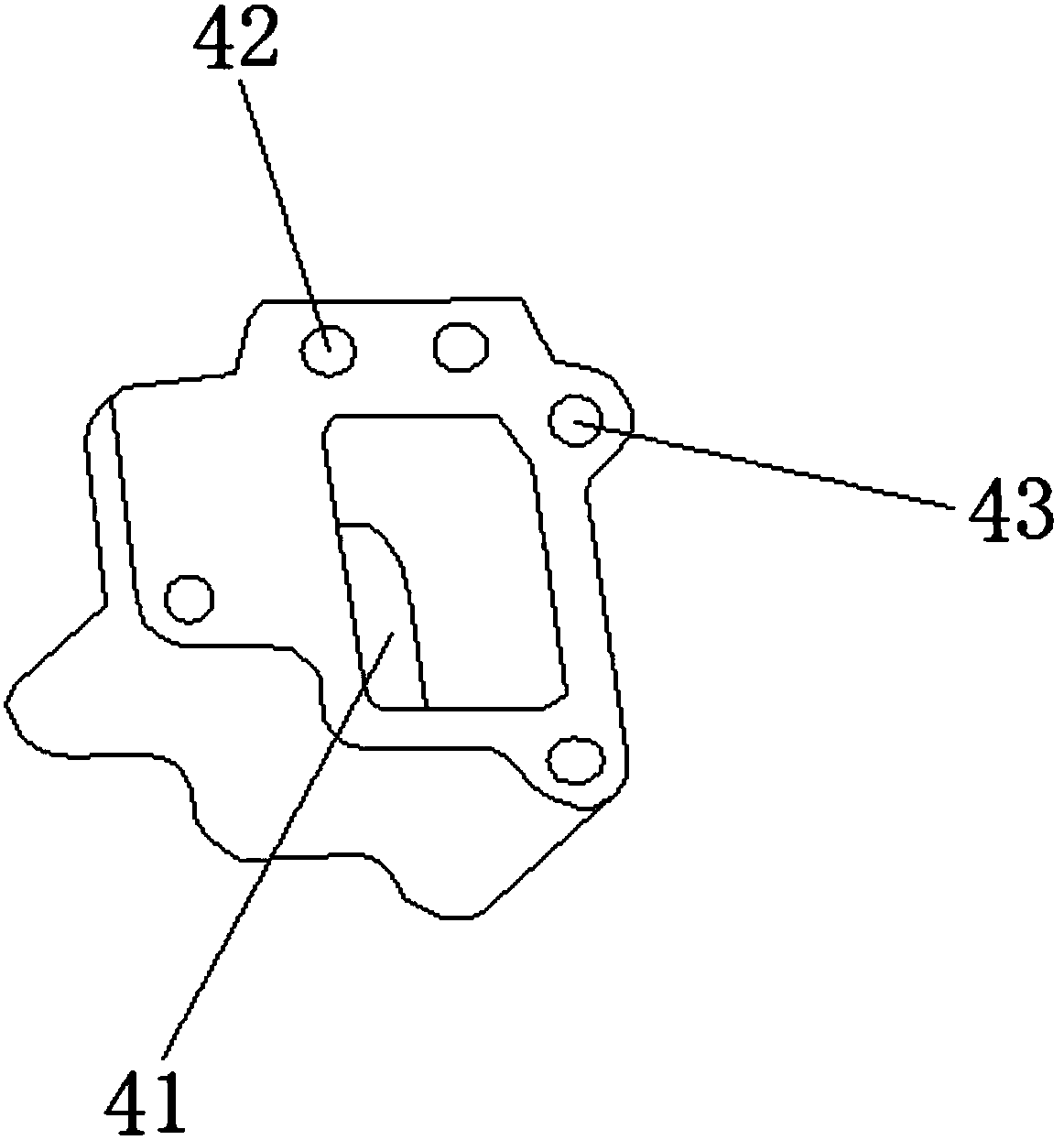

[0023] refer to Figure 1-3 As shown, a heavy-duty methanol engine multi-point injection nozzle structure of the present invention includes a common rail pipe 1 for splitting methanol, and multiple groups of nozzles whose number is consistent with the number of engine cylinders 2 are arranged on the common rail pipe 1 Assembly 3, that is, each cylinder of the engine corresponds to a group of nozzle assemblies 3, and each group of nozzle assemblies 3 includes at least two nozzles 31 that communicate the common rail pipe 1 with the engine cylinder 2, that is, at least two nozzles are correspondingly arranged on each cylinder 31. The same flow rate is split and injected by at least two nozzles 31, which reduces the methanol flow rate of a single nozzle 31, and each nozzle 31 is arranged obliquely toward the side wall of the engine cylinder 2, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com