Preparation method of moissanite blade

A technology of moissanite and blade material, which is applied in the field of preparation of moissanite blade material, can solve the problems of restricting production capacity and in-depth development of products, low crushing efficiency, and aerosol generation, so as to avoid insufficient logistics vector, high crushing efficiency, The effect of speeding up the collision speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

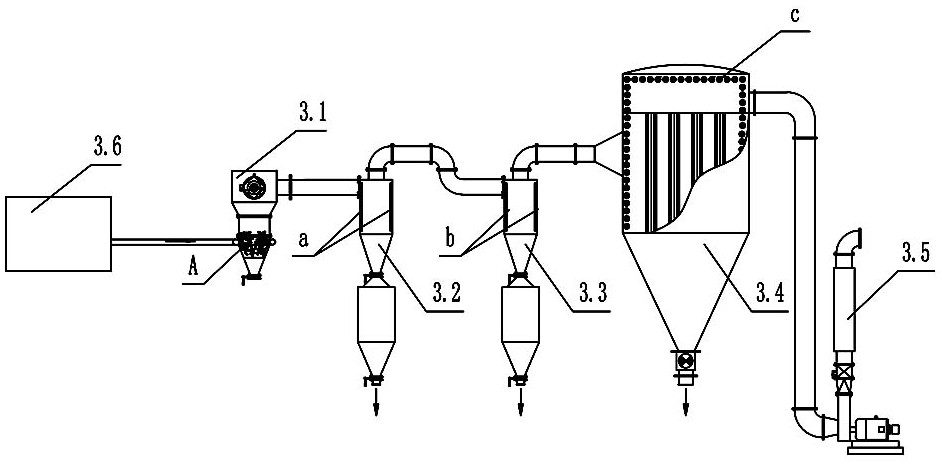

[0015] The preparation method of moissanite granular material according to the present invention is mainly prepared according to the steps of "hammer crusher pulverization → ball mill pulverization → steam flow medium pulverization classification → moisture classification and impurity removal → filter press dehydration → drying and packaging" to prepare 0.5μm moissanite particles.

[0016] The specific preparation steps are described below with specific examples, including:

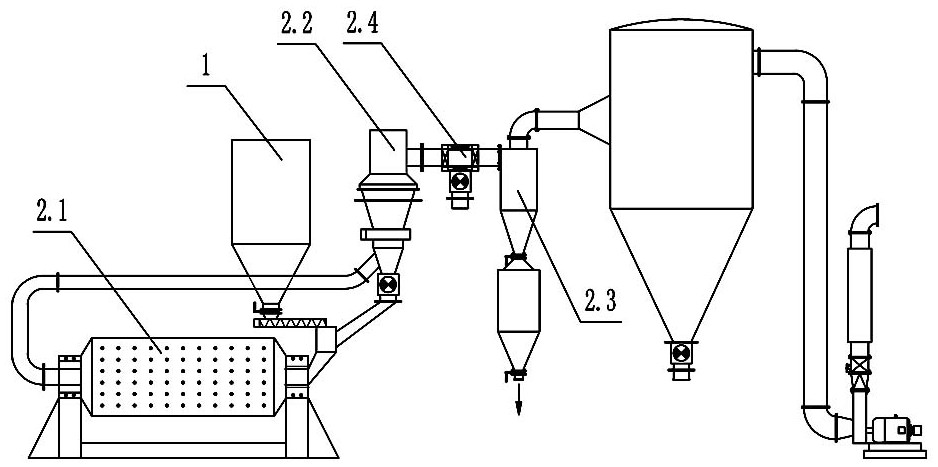

[0017] In the first step, put the artificially synthesized moissanite crystal columnar block (diameter 28mm, height 50mm) into the hammer crusher for crushing, set the feed rate of the hammer crusher to 300kg / h, and screen through the hammer crusher filter Take out 1-3mm pellets and put them into bin 1 (see figure 1 ).

[0018] In the second step, at a feed rate of 1200kg / h, the granular material in the bin 1 is transferred to the computer-controlled superhard material horizontal ball mill 2.1 for grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com