Combined thin-walled beam power absorbing method in trolley collision test

A crash test, thin-wall beam technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problem of high initial peak value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

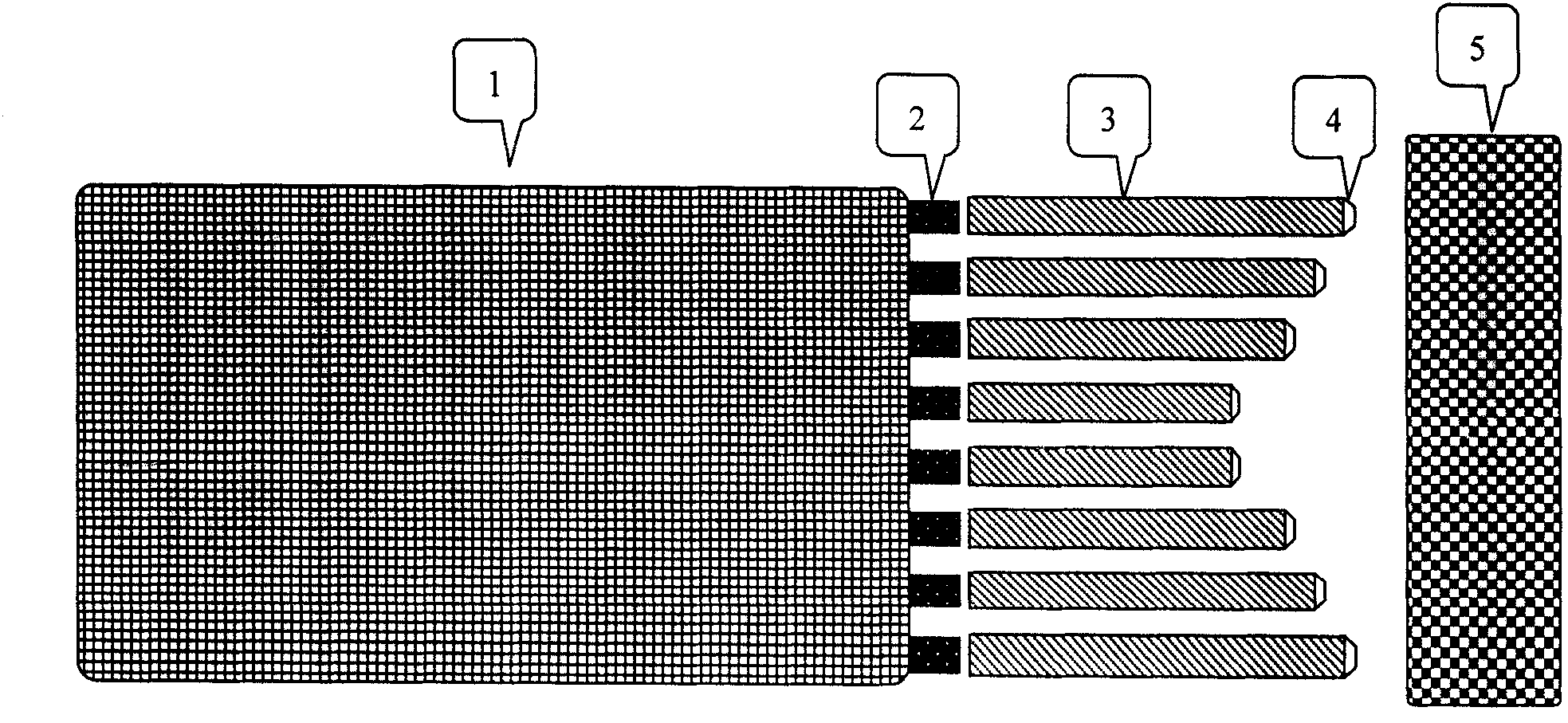

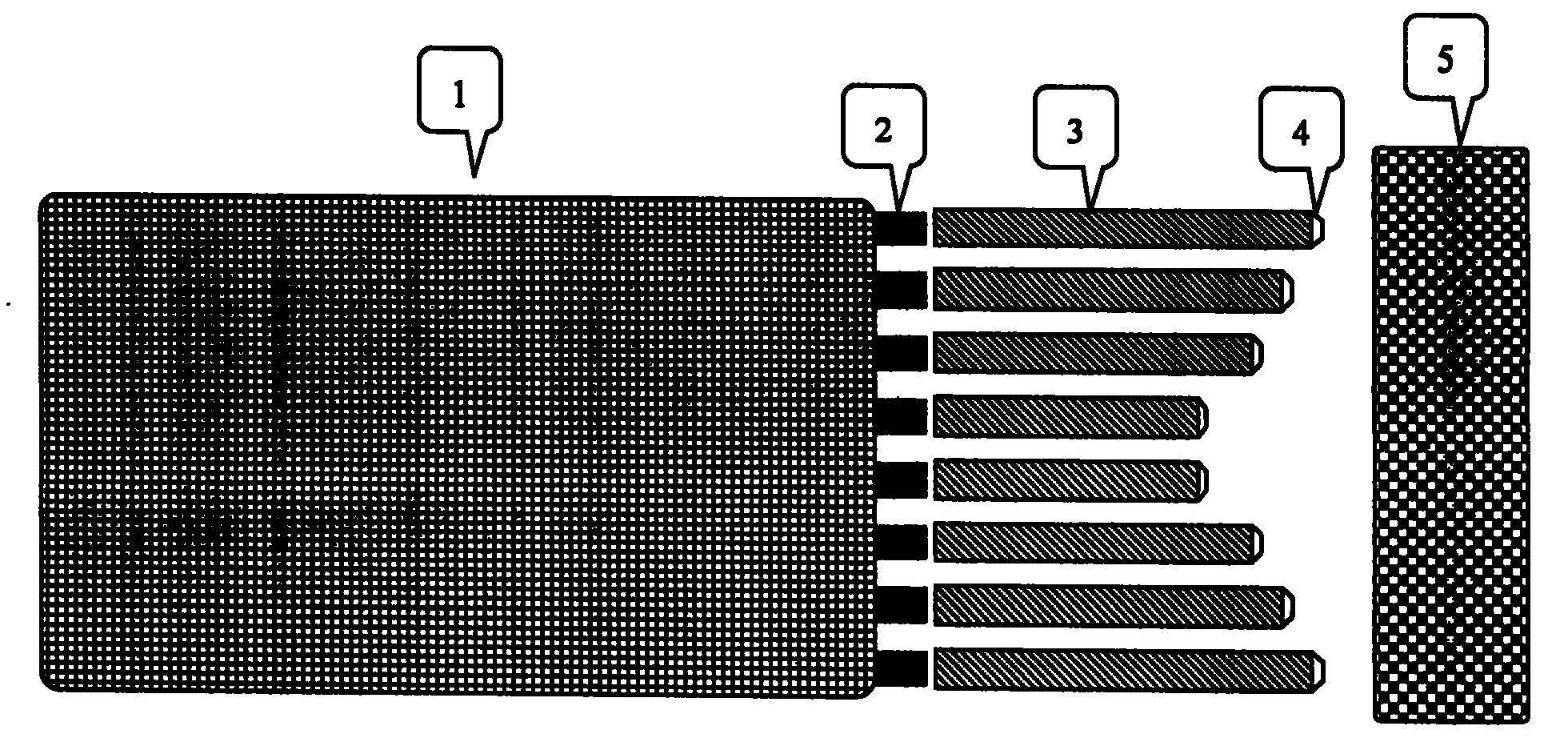

[0014] Example: The mass of the trolley is 750 kg, the collision speed is 50km / h, the peak value of the deceleration required in the experiment shall not exceed 28G, the duration of the deceleration greater than 20G shall not be less than 30ms, the deceleration curve is located in a band, and the experimental temperature is 20°C. According to the requirements of the experiment, six thin-walled square tubes with lengths of 850, 780, 720, 720, 780, and 850 and a wall thickness of 1.5 mm were selected to form a combined thin-walled square tube energy-absorbing method. Put 6 thin-walled square tubes on the thin-walled square tube mounting seat of the trolley in sequence, and use a tool to bend the thin-walled square tube by 45° at the front end 20mm of each thin-walled square tube to produce pre-deformation. The traction system accelerates the trolley to 50km / h and directly hits the fixed barrier. Do not place planks or other cushioning materials on fixed barriers. The experiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com