100% low floor tramcar non-power bogie and tramcar

A technology for trams and bogies, which is applied in the direction of the bogie, the device for lateral relative movement between the underframe and the bogie, the parts of the railway car body, etc. , wear and other problems, to achieve the effect of increasing service life, good guidance and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

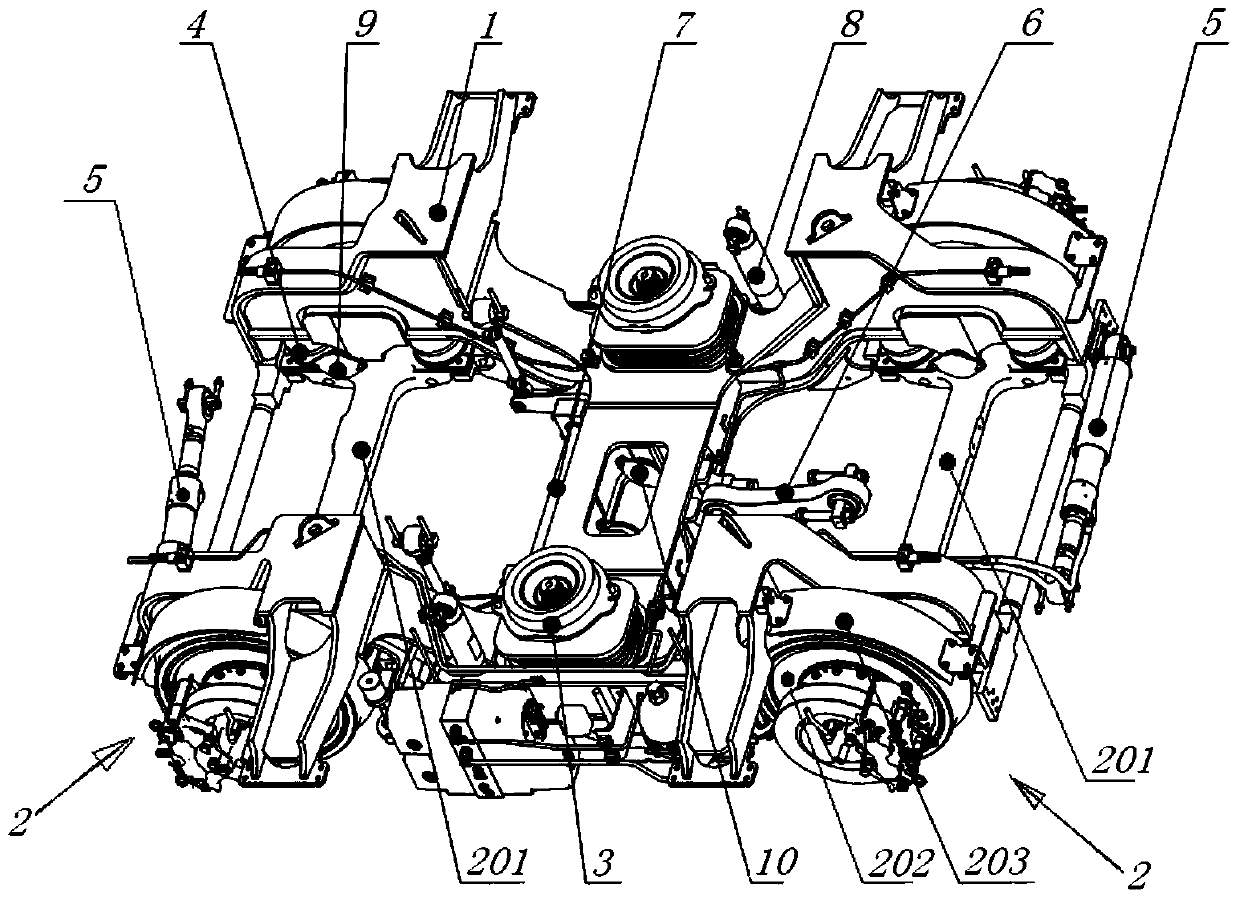

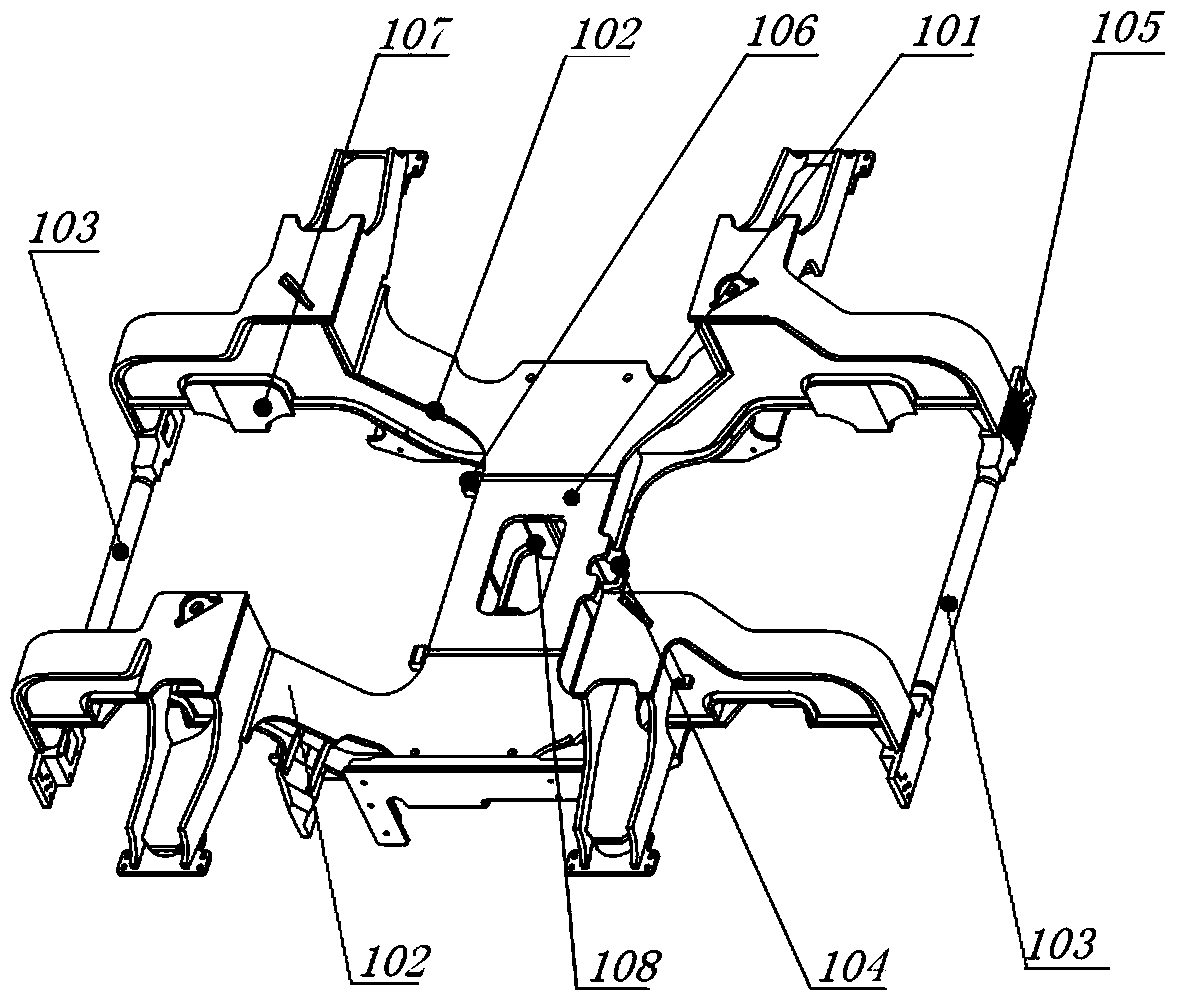

[0012] In order to make the purpose, technical solutions and advantages of the invention more clear, the technical solutions in the embodiments of the invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the invention. Obviously, the described embodiments are Invention type some embodiments, but not all embodiments.

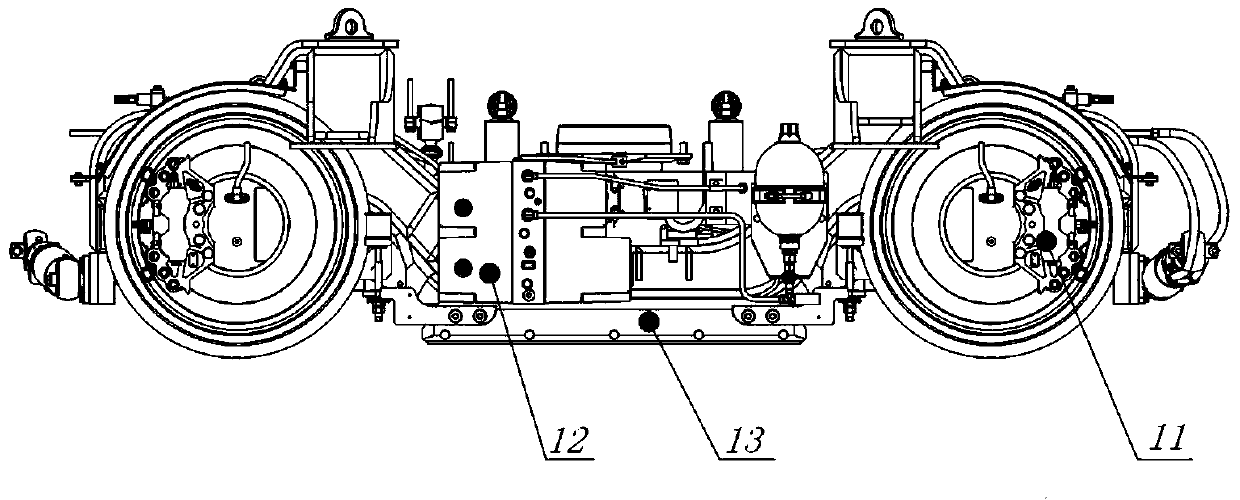

[0013] Embodiments of the present invention provide a 100% low-floor tram non-powered bogie, such as figure 1 As shown, the non-power bogie includes a bogie frame 1, and anti-kink devices are arranged at both ends of the bogie frame 1. The anti-kink device specifically includes a hydraulic cylinder 5 provided at the end of the bogie frame 1, the piston of the hydraulic cylinder 5 is connected to the vehicle body, so that the piston of the hydraulic cylinder 5 moves under the control of the control system, thereby adjusting the bogie frame 1 and the vehicle body. relative position.

[0014] The working p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com