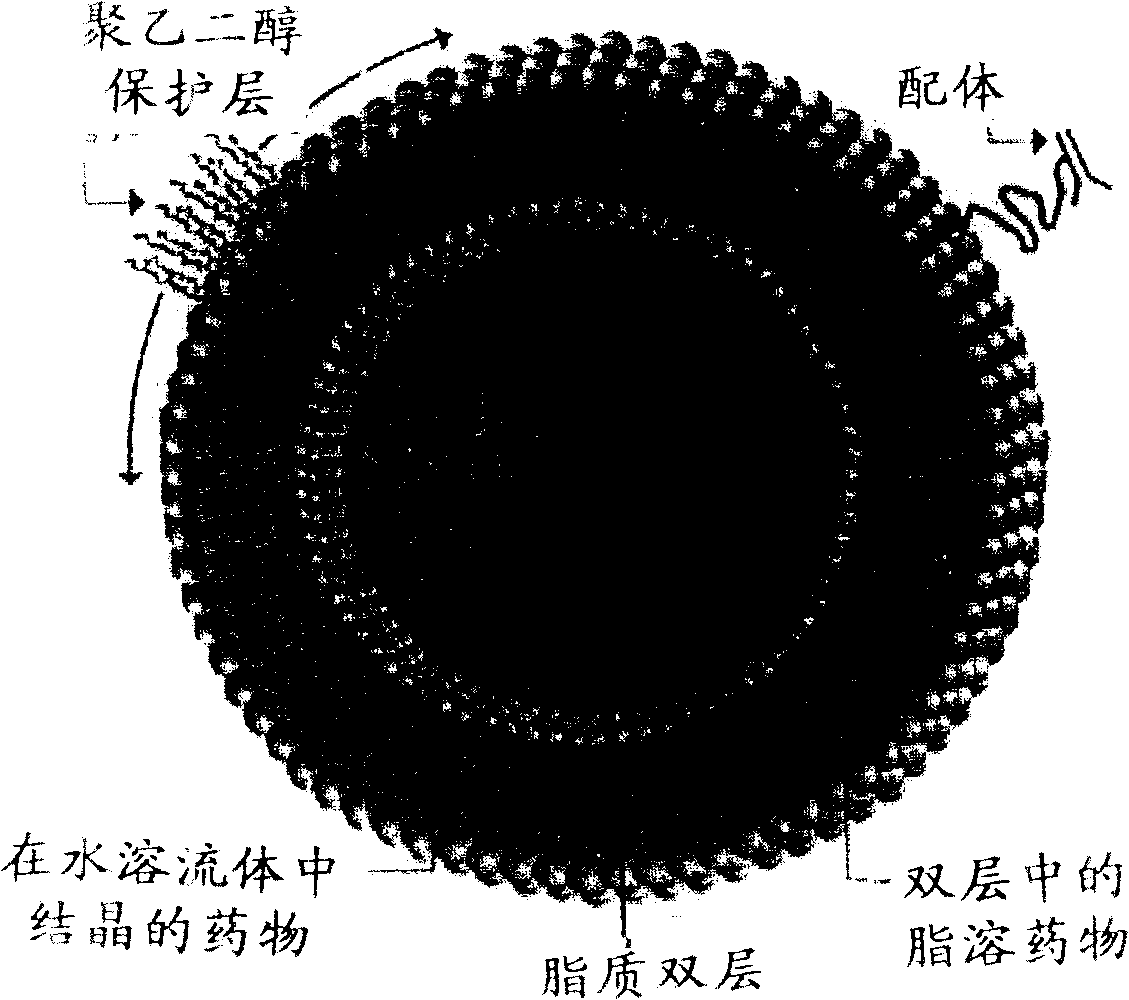

Biological endophilic ligand numerator mediated target liposome, preparation and uses thereof

A technology targeting liposomes and affinity, which is applied in liposome delivery, organic active ingredients, medical preparations of non-active ingredients, etc., which can solve the problems of low antibody affinity, fast clearance, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation prescription (25 ml capacity)

[0051] TAX 50mg

[0052] EPC 1850mg

[0053] Targeted Phospholipids 75mg

[0054] DSPG 75mg

[0055] Sucrose 2500mg

[0056] Preparation process one:

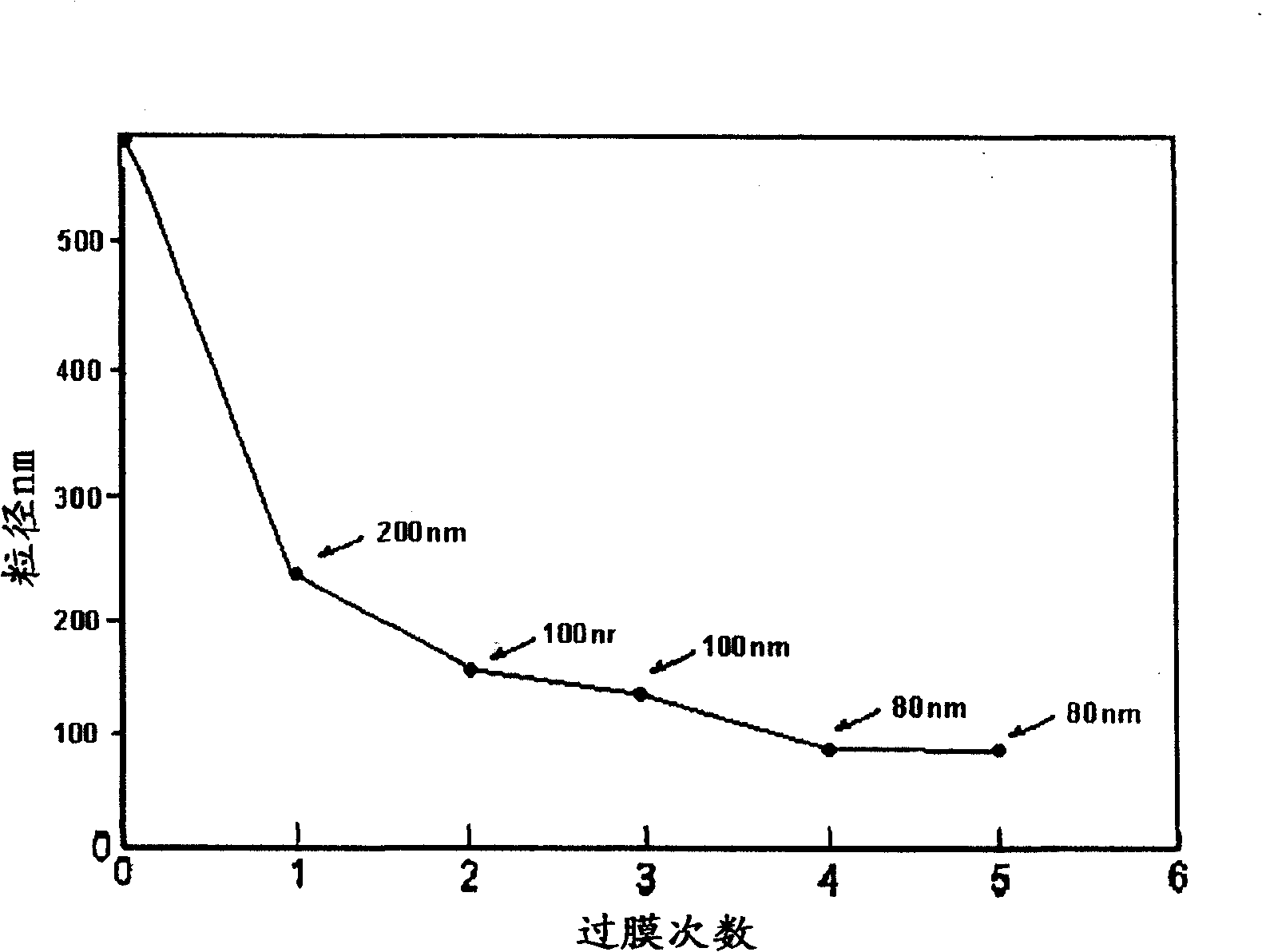

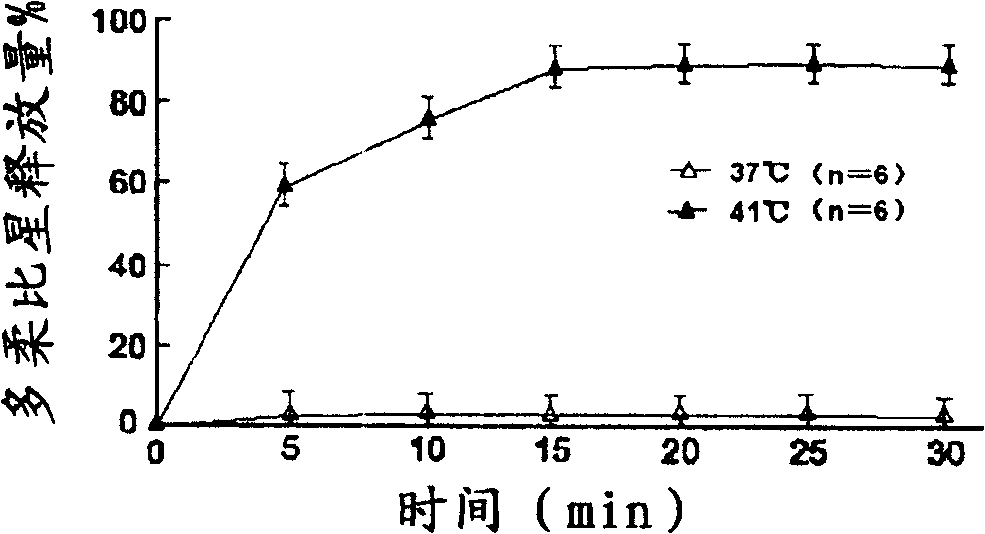

[0057] Add EPC, targeted phospholipids and DSPG into a round bottom flask according to the prescription ratio, add dichloromethane-methanol-water mixed solvent to dissolve, and remove the solvent by rotary evaporation under reduced pressure at 45°C. The phospholipid forms a film on the inner wall of the round bottom flask, and the prepared film is dried under vacuum for 20 hours to ensure that the organic solvent is completely removed. Add PBS buffer (Ph6.5) to the prepared film, hydrate at 45-60°C for 1 hour to obtain multilamellar liposomes (MLVs), and pass the prepared MLVs sequentially through the pores at a temperature greater than 45°C and high pressure On polycarbonate membranes of 200nm, 100nm, and 80nm, obtain large unilamellar liposomes (LUVs) with a particle si...

Embodiment 2

[0067] prescription:

[0068] TAX 50mg

[0069] EPC 1950mg

[0070] Targeted Phospholipids 25mg

[0071] CHOL 50mg

[0072] Lactose 1250mg

[0073] Preparation Process:

[0074] Add EPC and targeted phospholipids into a round bottom flask according to the prescription ratio, add dichloromethane / chloroform-methanol-water mixed solvent to dissolve, and remove the solvent by rotary evaporation under reduced pressure at 45°C. The phospholipid forms a film on the inner wall of the round bottom flask, and the prepared film is dried under vacuum for 20 hours to ensure that the organic solvent is completely removed. Add PBS (Ph6.5) to the prepared film and hydrate at 45-60°C for 1 hour to obtain multilamellar liposomes (MLVs) with a phospholipid concentration of 50 mg / ml, which will be prepared under high-pressure conditions at a temperature greater than 45°C The MLVs are in, pass through polycarbonate membranes with pore sizes of 200nm, 100nm, and 80nm in turn to obtain large u...

Embodiment 3

[0078] Preparation prescription (25ml capacity):

[0079] TAX 50mg

[0080] EPC 1600mg

[0081] Targeted Phospholipids 100mg

[0082] DPPG 25mg

[0083] PEG2000-DSPE 280mg

[0084] Mannitol 3750mg

[0085] Preparation process one:

[0086] Add the phospholipid into the round bottom flask according to the recipe ratio, add dichloromethane-methanol-water mixed solvent to dissolve, and remove the solvent by rotary evaporation under reduced pressure at 45°C. The phospholipid forms a film on the inner wall of the round bottom flask, and the prepared film is dried under vacuum for 20 hours to ensure that the organic solvent is completely removed. Add PBS buffer (Ph6.5) to the prepared film, and hydrate at 45-60°C for 1 hour to obtain multilamellar liposomes (MLVs), with a phospholipid concentration of 50 mg / ml. The prepared MLVs pass through polycarbonate membranes with apertures of 200nm, 100nm, and 80nm successively to obtain large unilamellar liposomes (LUVs) with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com