Linseed oil microcapsules and preparation method thereof

A technology of linseed oil and microcapsules, which is applied in the fields of fat oil/fat refining, fat oil/fat production, and fat-containing food ingredients, etc. Emulsification and film-forming properties of the product, etc., to achieve the effects of large-scale production, good taste and flavor, and good storage stability

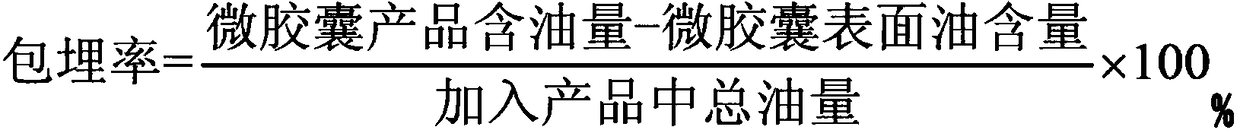

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of linseed oil microcapsules, comprising the following steps:

[0027] 1) Extraction of linseed oil by enzymatic hydrolysis: take 100g of linseed, after crushing, mix linseed with water at a mass ratio of 1:4, stir for 30-50 minutes, adjust the reaction temperature to 50-60°C, and use NaOH solution Adjust the pH to 8.5, add alkaline protease with a mass percentage of 2.0% (based on the total mass of the substrate), react for 4.5h, then adjust the temperature to 40-50°C, adjust the pH to 4.5-5.5 with HCL, add Composite cellulase with a mass percentage of 1.0-1.5% (based on the total mass of the substrate), the enzymolysis time is 4-5h, centrifuged at 3200rpm to obtain free oil 1, emulsion, hydrolyzate and slag , and then the obtained emulsion is subjected to secondary centrifugation to obtain free oil 2, and free oil 1 and free oil 2 are combined to form linseed oil, and the oil yield of linseed is 81.67%. ;

[0028] 2) Prepare the water phase: add...

Embodiment 2

[0037] A preparation method of linseed oil microcapsules, comprising the following steps:

[0038]1) Extraction of linseed oil by enzymatic hydrolysis: Take 150g of linseed, after crushing, mix linseed with water at a mass ratio of 1:5, stir for 40-60 minutes, adjust the reaction temperature to 55-65°C, and use NaOH solution Adjust the pH to 9.0, add alkaline protease with a mass percentage of 2.0% (based on the total mass of the substrate), react for 5.0 hours, then adjust the temperature to 50-60°C, adjust the pH to 5.0-6.0 with HCL, add Composite cellulase with a mass percentage of 1.2-1.7% (based on the total mass of the substrate), the enzymolysis time is 4.5-5.5h, centrifuged at 3500rpm to obtain free oil 1, emulsion, hydrolyzate and material Slag, then the obtained emulsion is subjected to secondary centrifugation to obtain free oil 2, and free oil 1 and free oil 2 are combined to form linseed oil, and the oil yield of linseed is 82.17%. ;

[0039] 2) Prepare the wate...

Embodiment 3

[0045] A preparation method of linseed oil microcapsules, comprising the following steps:

[0046] 1) Extraction of linseed oil by enzymatic hydrolysis: take 200g of linseed, after crushing, mix linseed with water at a mass ratio of 1:6, stir for 50-70 minutes, adjust the reaction temperature to 65-70°C, and use NaOH solution Adjust the pH to 9.0, add alkaline protease with a mass percentage of 2.0% (based on the total mass of the substrate), react for 6.0 hours, then adjust the temperature to 55-65°C, adjust the pH to 4.0-6.0 with HCL, add Composite cellulase with a mass percentage of 1.5-2.0% (based on the total mass of the substrate), the enzymolysis time is 5-6 hours, centrifuged at 3500rpm to obtain free oil 1, emulsion, hydrolyzate and slag , and then the obtained emulsion is subjected to secondary centrifugation to obtain free oil 2, and free oil 1 and free oil 2 are combined to form linseed oil, and the oil yield of linseed is 82.21%. ;

[0047] 2) Prepare the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com