Method for preparing high-color-developing zirconium-silicate-coated carbon black pigment by taking plant fiber as carbon source

A plant fiber, zirconium silicate technology, applied in the field of ceramic pigments, can solve the problems of unfavorable packaging, poor dispersion of zirconium silicate sol, low affinity, etc., and achieve the effect of broad market space, pure color and high packaging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

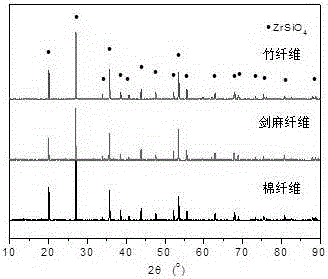

[0023] The sisal fiber was dried and dehydrated at 200°C, and the zirconium silicate sol was prepared by using the non-hydrolytic sol-gel method, that is, the molar ratio of ZrCl 4 : Ethyl Tetrasilicate: LiF=1:1.2:0.3 ratio ZrCl 4 , tetraethyl orthosilicate and LiF dissolved in isopropanol, where Zr 4+ The concentration is 1mol / L, after mixing evenly, reflux and heat at 110°C for 20 hours to obtain a zirconium silicate sol; then weigh 0.5g sisal fiber and ultrasonically disperse it in 13mL zirconium silicate sol, and then dry it in an oven at 100°C The dry gel was obtained in 6 hours; then heated at 5°C per minute to 900°C for 4 hours in a nitrogen atmosphere, and cooled with the furnace; then heated at 5°C per minute to 800°C for 2 hours in an air atmosphere to remove excess The wrapped carbon black obtains the zirconium silicate wrapped carbon black material.

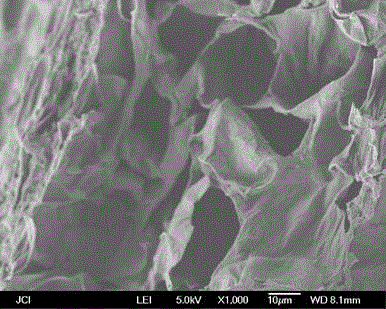

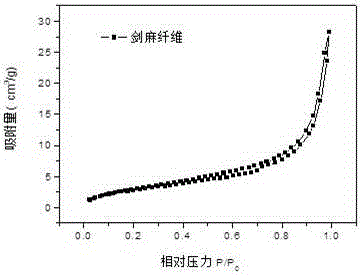

[0024] from figure 1 It can be observed that the sisal fiber is a porous structure; figure 2 The BET test also...

Embodiment 2

[0026] The preparation method and preparation conditions of this embodiment are the same as those of the above-mentioned Example 1. The difference is that the cotton fiber used is a carbon source, and the cotton fiber is dried and dehydrated at 150° C., and the molar ratio is zirconium acetate: silane coupling agent: Dissolve zirconium acetate, silane coupling agent and MgF in the ratio of MgF=1:1.1:0.2 in 13mL of ethanol solvent, then place it in a 25mL polyethylene-lined reactor, and take it out after solvothermal reaction at 100°C for 10 hours Finally, zirconium silicate sol was obtained; then 0.3 g of cotton fiber was weighed and ultrasonically dispersed in 13 mL of zirconium silicate sol, and then dried in an oven at 110° C. for 12 hours to obtain xerogel. Then, in a nitrogen atmosphere, the temperature was raised to 1050° C. for 4 hours at a rate of 5° C. per minute, and then cooled with the furnace. Then in an air atmosphere, heat up to 700°C at 5°C per minute and keep ...

Embodiment 3

[0029] The preparation method and preparation conditions of this embodiment and the above-mentioned embodiment 1 are the same, and the difference is that the rice straw fiber is used as the carbon source, and the molar ratio is zirconium isopropoxide: silicon tetrachloride: NaF=1:1.3:0.25 Ratio Dissolve zirconium isopropoxide, silicon tetrachloride and NaF in solvent toluene, where Zr 4+ The concentration is 1mol / L, and the zirconium silicate sol is obtained by microwave at 120°C for 0.5 hours in a commercially available microwave oven, and then 0.37g of rice straw fiber is weighed and placed in 13mL of zirconium silicate sol for 1 hour, and dried in an oven at 90°C for 20 After 1 hour to obtain dry gel; then in a nitrogen atmosphere at 5 ° C per minute to 750 ° C for 2 hours, followed by furnace cooling; then in an air atmosphere at 5 ° C per minute to 750 ° C for 2 hours to remove excess unwrapped The carbon black was obtained to obtain zirconium silicate wrapped carbon blac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color price | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com