Method for preparing microcapsule phase change material by using composite emulsifier

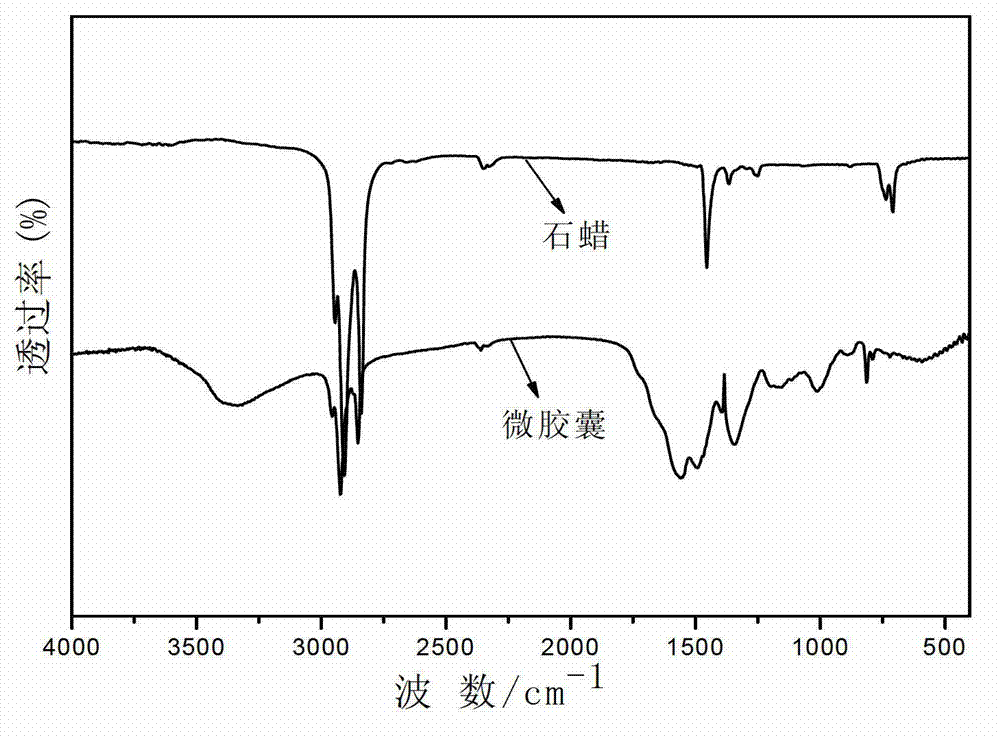

A composite emulsifier and phase change material technology, applied in microcapsule preparations, chemical instruments and methods, microsphere preparation, etc., can solve the problems of polluted environment, uneven dispersion, volume change, etc., and achieve high encapsulation rate, particle size Evenly distributed, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

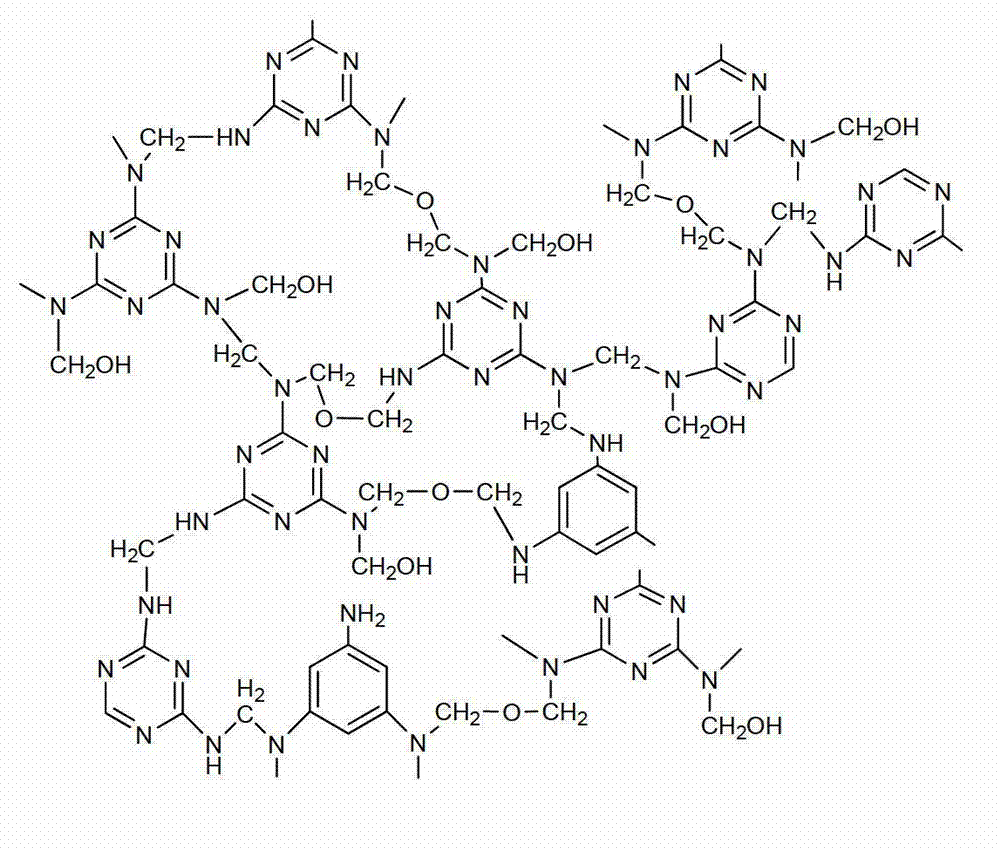

[0023] One, the preparation of melamine-formaldehyde prepolymer

[0024] Put a certain amount of melamine, formaldehyde aqueous solution (37-40wt%) and deionized water into a 150mL three-necked flask, adjust the pH value of the mixed solution to 8.5-9.0 with 10% triethanolamine, and stir in a constant temperature water bath at 70°C React until the mixed solution is completely transparent to obtain a prepolymer solution, which is set aside.

[0025] 2. Preparation of oil-in-water emulsion

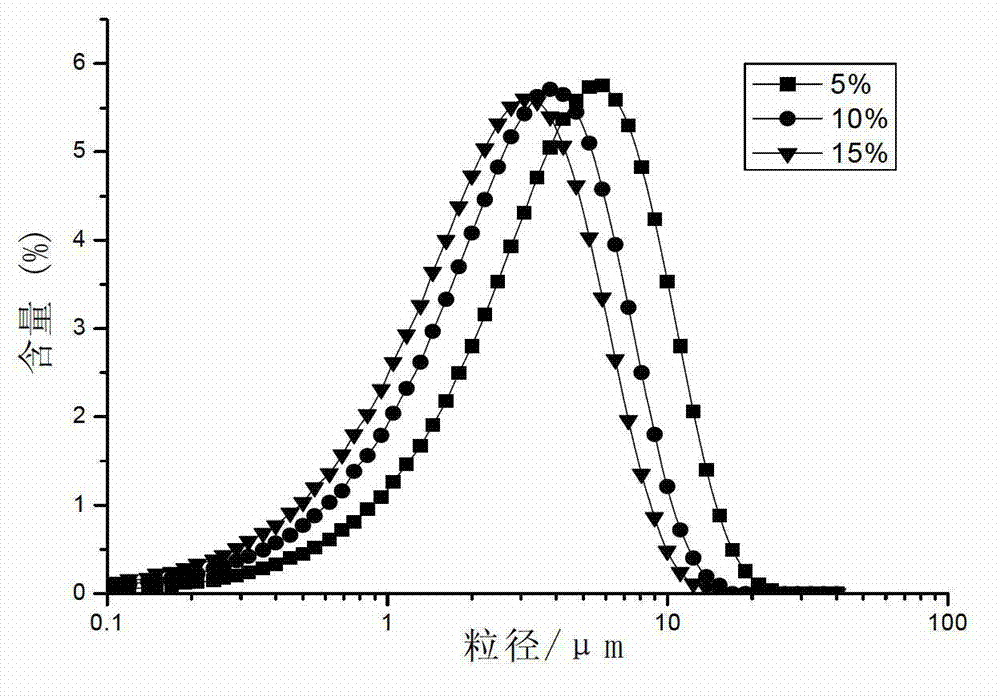

[0026] Uniformly disperse the oil phase monomer in the water phase to form an oil-in-water (o / w) emulsion, the shear speed is 1500-3000rpm, and the amount of compound emulsifier is 5-15% of the core material content, emulsifying the oil-water of paraffin The ratio is 1:3-1:10. Specific steps:

[0027] (1) Add a certain amount of distilled water (the ratio of oil to water is 1:3-1:10) and Tween 20 (Tween 20 accounts for 66% of the total mass of the emulsifier) into a 300mL beaker with a ...

Embodiment 1

[0037] One, the preparation of melamine-formaldehyde prepolymer

[0038] Put 2.92g of melamine, 5.8mL of formaldehyde solution (37-40wt%) and 20mL of deionized water into a 150mL three-necked flask, and adjust the pH value of the mixed solution to 8.5-9.0 with 10wt% triethanolamine (about 5-6 drops) , put it in a constant temperature water bath at 70°C and stir until the mixed solution is completely transparent, and keep it warm for 30 minutes to obtain a prepolymer solution, which is ready for use

[0039] 2. Preparation of oil-in-water emulsion

[0040] (1) Add 50mL of distilled water and 0.66g of Tween 20 into a 300mL beaker with a thermometer and mechanical stirring, heat the water bath to 50°C, and stir at 500r / min for 15 minutes to prepare an emulsifier aqueous solution.

[0041] (2) Slowly add the mixed solution of 10g phase-change paraffin and 0.34g Span 80 into the emulsified aqueous solution, keep the temperature of the water bath at 50°C, increase the speed to 3000...

Embodiment 2

[0045] One, the preparation of melamine-formaldehyde prepolymer: with embodiment 1.

[0046] 2. Preparation of oil-in-water emulsion

[0047] (1) Add 50mL of distilled water and 0.33g of Tween 20 into a 300ml beaker with a thermometer and mechanical stirring, heat in a water bath to 50°C, and stir at 500r / min for 15 minutes to prepare an aqueous emulsifier solution.

[0048] (2) Slowly add the mixed solution of 10g phase-change paraffin and 0.17g Span 80 into the emulsified aqueous solution, keep the temperature of the water bath at 50°C, increase the speed to 3000r / min, and stir rapidly for 30min to obtain a stable oil-in-water (o / w) lotion.

[0049] Three, microencapsulation process: with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com