Method for synthesizing polypyrrole microcapsules

A technology of microcapsules and polypyrrole, which is applied in the field of polypyrrole synthesis, can solve problems such as the impact on human body and environment, the toxicity of chloroform, and its volatility, and achieve the effect of low cost, low price and easy purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

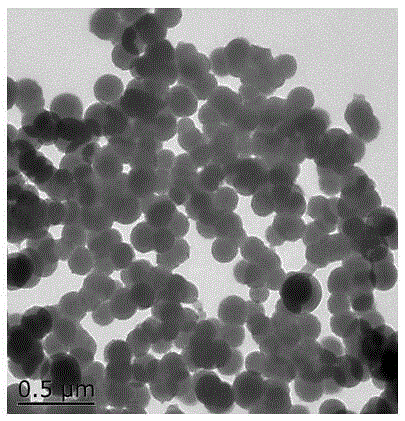

Embodiment 1

[0031] Add 40mL of water, 4.0g of benzoyl peroxide, 0.20g of sodium lauryl sulfate, 0.32g of polyethylene glycol 2000 into a 100ml three-neck flask, add a small amount of butanol and ethanol dropwise, stir mechanically for 1 hour, then add Peracetic acid, adjust the pH of the solution to about 2, add the refrigerated pyrrole monomer dropwise, continue to stir for 4-6 hours, and finally get a black substance, remove the black substance, wash once with cyclohexane, and wash with absolute ethanol for 3 Once, vacuum-dried at 60°C for 24 hours to obtain the product. The obtained product was characterized by transmission, its dispersion performance was compared, and the encapsulation rate was measured. The encapsulation rate of microcapsules was 91.8%. Obtained microcapsules TEM see figure 1 shown.

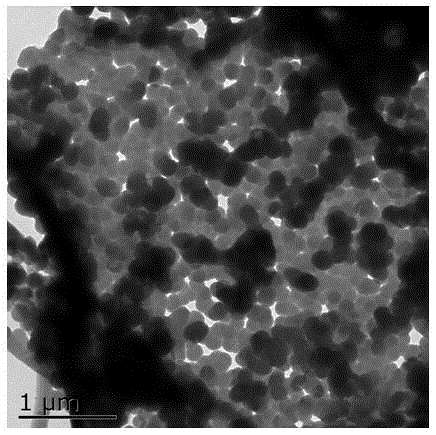

Embodiment 2

[0033]Add 40mL water into a 100ml three-necked flask, add 3.8g benzoyl peroxide, 0.16g sodium lauryl sulfate, 0.34g polyethylene glycol 600, drop a small amount of butanol and ethanol, stir mechanically for 1 hour, then add Peracetic acid, adjust the pH of the solution to about 3, add the refrigerated pyrrole monomer dropwise, continue to stir for 4-6 hours, and finally obtain a black substance, remove the black substance, wash once with cyclohexane, and wash with absolute ethanol for 3 Once, vacuum-dried at 60°C for 24 hours to obtain the product. The obtained product was characterized by transmission, its dispersion performance was compared, and the encapsulation rate was measured. The encapsulation rate of microcapsules was 90.1%. Obtained microcapsules TEM see figure 2 shown.

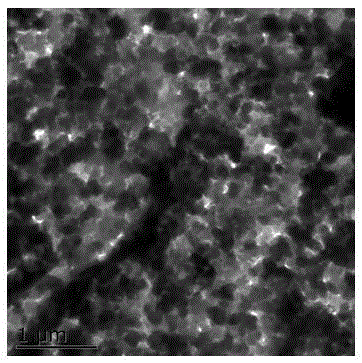

Embodiment 3

[0035] Add 40mL water into a 100ml three-necked flask, add 3.7g benzoyl peroxide, 0.24g sodium lauryl sulfate, 0.28g polyethylene glycol 600, drop a small amount of butanol and ethanol, stir mechanically for 1 hour, then add Peracetic acid, adjust the pH of the solution to about 4, add the refrigerated pyrrole monomer dropwise, continue to stir for 4-6 hours, and finally obtain a black substance, remove the black substance, wash once with cyclohexane, and wash with absolute ethanol for 3 Once, vacuum-dried at 60°C for 24 hours to obtain the product. The obtained product was characterized by transmission, its dispersion performance was compared, and the encapsulation rate was measured. The encapsulation rate of microcapsules was 89.5%. Obtained microcapsules TEM see image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com