Preparation method of zirconium-silicate-coated cerium sulfide scarlet pigment and product prepared by same

A cerium sulfide and encapsulation technology, which is applied in the field of inorganic pigments, can solve the problems that restrict the performance improvement of cerium sulfide red pigment products and the expansion of application fields, and achieve high temperature stability and chemical stability, good dispersion, and low energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

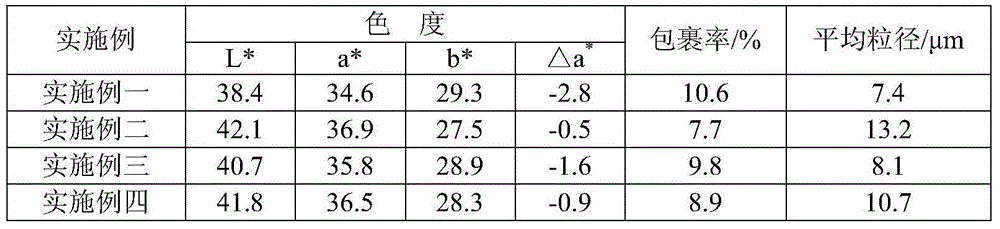

Examples

Embodiment 1

[0023] The preparation method of zirconium silicate wrapped type cerium sulfide bright red material of this embodiment, its steps are as follows:

[0024] (1) Preparation of raw material solution

[0025] Cerium sulfide suspension: 0.01mol γ-Ce 2 S 3 After the color material is dispersed in 30mL deionized water, add 0.4g dispersant CTAB, and ultrasonically disperse and homogenize for 30min under magnetic stirring to obtain a suspension of cerium sulfide;

[0026] Zirconium source solution: 0.03mol ZrClO 2 ·8H 2 Dissolve O in 50 mL of deionized water and stir evenly, add 0.036 mol of citric acid and 0.018 mol of NaF with magnetic stirring to homogenize to obtain a zirconium source solution;

[0027] Silicon source solution: Mix 0.027mol TEOS with 10ml absolute ethanol to obtain a silicon source solution;

[0028] (2) adding the silicon source solution into the zirconium source solution with magnetic stirring and mixing, and after homogenization, adjust the pH value of the ...

Embodiment 2

[0032] The preparation method of zirconium silicate wrapped type cerium sulfide bright red material of this embodiment, its steps are as follows:

[0033] (1) Preparation of raw material solution

[0034] Cerium sulfide suspension: 0.0075mol γ-Ce 2 S 3 After the color material is dispersed in 20mL of deionized water, mix with a solution formed by dissolving 0.3g of dispersant sodium dodecylsulfonate (SDS) in 5ml of ethanol, and ultrasonically disperse and homogenize for 30min under magnetic stirring to obtain a cerium sulfide suspension;

[0035] Zirconium source solution: 0.0195mol ZrClO 2 ·8H 2 O was dissolved in 40mL deionized water and stirred evenly, adding 0.021mol citric acid and 0.009mol CaF 2 Magnetic stirring is used to homogenize it to obtain a zirconium source solution;

[0036] Silicon source solution: Mix 0.015mol TEOS with 10ml absolute ethanol to obtain a silicon source solution;

[0037] (2) adding the silicon source solution into the zirconium source solu...

Embodiment 3

[0041] The preparation method of zirconium silicate wrapped type cerium sulfide bright red material of this embodiment, its steps are as follows:

[0042] (1) Preparation of raw material solution

[0043] Cerium sulfide suspension: 0.008mol γ-Ce 2 S 3 After the color material is dispersed in 30mL of deionized water, add 0.60g of dispersant PVP, and ultrasonically disperse and homogenize for 30min under magnetic stirring to obtain a suspension of cerium sulfide;

[0044] Zirconium source solution: 0.034mol ZrCl 4 Dissolve in 50mL deionized water and stir evenly, add 0.041mol citric acid and 0.016mol NaF magnetically stir to homogenize to obtain zirconium source solution;

[0045] Silicon source solution: Mix 0.027mol TEOS with 10ml absolute ethanol to obtain a silicon source solution;

[0046] (2) adding the silicon source solution into the zirconium source solution and stirring and mixing, after homogenization, adjust the pH value of the mixed solution to 11 with NaOH to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com